Trimethylolpropane Trimethacrylate CAS 3290-92-4

Trimethylolpropane Trimethacrylate CAS 3290-92-4 With Best Quality

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Trimethylolpropane Trimethacrylate

CAS: 3290-92-4

MOQ: 1KG

Directory Guidance on Trimethylolpropane Trimethacrylate

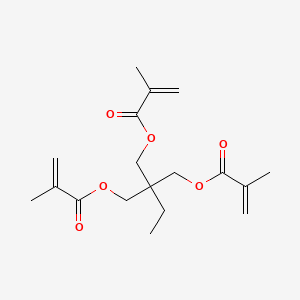

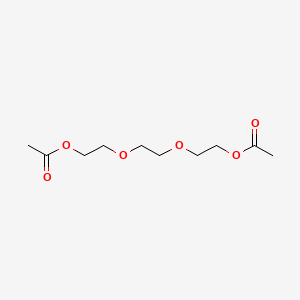

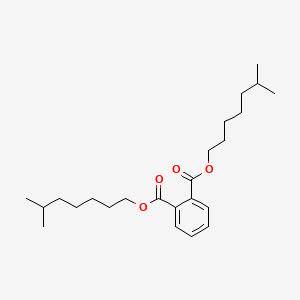

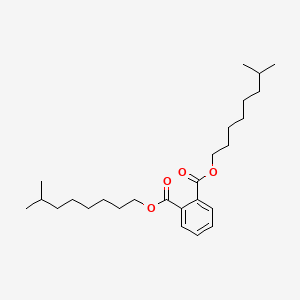

Chemical Structure

Basic Info:

| Melting point | -25°C |

| Boiling point | >200°C 1mm |

| density | 1.06 g/mL at 25 °C (lit.) |

| vapor density | >1 (vs air) |

| vapor pressure | <0.01 mm Hg ( 20 °C) |

| refractive index | n20/D 1.472(lit.) |

Product Introduction:

In terms of physical properties, Trimethylolpropane Trimethacrylate has a density of about 1.06 g/mL and a refractive index of 1.472 at 25 ° C. It is almost insoluble in water, but it dissolves well in common organic solvents such as alcohols and esters. This compound has a low melting point, about -25 ° C, and a boiling point above 200 ° C at 1mm Hg pressure. Its flash point is high, exceeding 230°F, so it is relatively safe to store and transport at room temperature, but care should still be taken to avoid contact with eyes and skin to prevent irritation.

From a synthetic point of view, Trimethylolpropane Trimethacrylate is usually prepared by esterification of trimethylolpropane with methacrylic acid. As an important polyhydroxyl compound, trimethylol propane can be esterified with carboxylic acid to produce ester compounds with different functional groups. This synthesis process not only has mild reaction conditions, but also has high purity of the product, which is suitable for large-scale industrial production.

In the field of application, Trimethylolpropane Trimethacrylate is widely used in many industries due to its unique chemical structure and properties. It is often used as a crosslinking agent to synthesize high performance resin materials, which can significantly improve the mechanical strength, heat resistance and chemical stability of the resin. In addition, it is used to make UV-curing coatings and adhesives, which can cure quickly under light to form a hard protective film and are widely used in industries such as electronics, automotive and construction.

Nature and Specifications:

| Item | Specification |

| Product Name | Trimethylolpropane Trimethacrylate |

| CAS No. | 3290-92-4 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | >230 °F |

| storage temp. | under inert gas (nitrogen or Argon) at 2-8°C |

| solubility | Insoluble in water |

| form | liquid |

| color | Color Colorless to yellowish |

| Odor | slightly ester-like |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Trimethylolpropane Trimethacrylate (TMPT) is an outstanding multi-functional monomer with unique chemical structure and excellent properties, widely utilized across numerous fields due to its application in multiple fields.

Trimethylolpropane Trimethacrylate is one of the primary raw materials for UV-cured coatings in the coatings industry, due to its highly reactive nature and quick cross-link curing under ultraviolet light. Due to this property, Trimethylolpropane Trimmethacrylate forms hard coatings with excellent wear resistance, chemical resistance and gloss that have become widely used as protective layers on cars, electronics products and furniture surfaces. Furthermore, Trimethylolpropane Trimethacrylate can also act as reactive diluents to adjust viscosity and curing speeds thereby optimizing construction performance of coatings applications.

Trimethylolpropane Trimethacrylate adhesives provide high performance pressure sensitive adhesives and structural adhesives, with multifunctional properties to increase cross-linking density of cross-linked bonds, increasing bond strength and durability. It excels in areas such as electronic device assembly, automotive parts bonding, building sealing or anywhere fast curing with strong bond strength is required.

Trimethylolpropane Trimethacrylate is often employed in the synthesis of resin materials as a crosslinker or chain extender, crosslinking with various resin types such as polyurethane, epoxy, and unsaturated polyester resins to produce materials with greater mechanical strength and thermal stability. When added to polyurethane resin it can drastically increase both hardness and wear resistance for use in sports equipment manufacturing or industrial part manufacturing applications.

Trimethylolpropane Trimethacrylate’s high purity and low volatility makes it an ideal material for electronic packaging in the electronics industry. It can be used to produce photoresist, electronic inks and insulating coatings used extensively in semiconductor production, circuit board packaging and microelectronic devices; its fast curing time and strong adhesion properties help shield components from environmental elements.

Trimethylolpropane Trimethacrylate can also be found in cosmetics products as a film forming agent and hair conditioner, providing a flexible film used in hair styling products and nail polish to provide shine and durability.

Trimethylolpropane Trimethacrylate shows significant advantages in industrial applications due to its unique combination of molecular structure and properties. The three methacrylate groups in the molecule give it high reactivity, which can quickly participate in free radical polymerization and form a dense cross-linked network. This feature enables rapid film formation in seconds in UV-curable coatings, reduces curing time by more than 40% in electronic packaging materials, and provides stronger bond strength for adhesives, significantly increasing production efficiency.

The cross-linked Trimethylolpropane Trimethacrylate polymer system has excellent physical and chemical stability. The mechanical strength of the material is increased to 2-3 times that of traditional resin, and the wear resistance can meet the needs of high-frequency friction scenarios. In the field of plastic modification, the addition of 5%-8% Trimethylolpropane Trimethacrylate can raise the heat resistance temperature of the material to more than 120℃, while maintaining the impact resistance retention rate of more than 85%. Its excellent electrical insulation (dielectric constant < 3.0) and radiation resistance make it the preferred component of packaging materials for 5G communications equipment.

The versatility of the compound covers multiple industrial scenarios. As a crosslinking agent, it can replace more than 30% organic peroxide in rubber vulcanization system, and improve the aging resistance of products simultaneously; As a reactive diluent, the viscosity of the coating can be adjusted to the suitable range of 200-500mPa·s. In the field of cosmetics, the flexible film formed by it can achieve a lasting setting effect of more than 48 hours, and the elution rate is less than 15%, avoiding the hair damage caused by traditional styling agents.

From an environmental perspective, the production of Trimethylolpropane Trimethacrylate uses a solvo-free process, and VOC emissions are reduced by more than 90% compared with traditional processes. The volatile organic matter content of the cured product is < 50μg/m³, which conforms to the EU REACH regulation standard. In the application of electronic adhesives, its low toxicity characteristics reduce the concentration of benzene series in the workshop working environment by 70%, significantly reducing occupational health risks.

In terms of economy, the industrial production cost of Trimethylolpropane Trimethacrylate is 18%-22% lower than that of similar crosslinkers. In the production of automotive seals, the addition of this material can shorten the vulcanization cycle by 25%, reduce energy consumption by 30%, and improve the product qualification rate to more than 99.5%. This cost advantage combined with the dual benefits of improved performance makes it penetrate rapidly in emerging fields such as new energy battery packaging and photovoltaic backplane bonding.

In summary, Trimethylolpropane Trimethacrylate achieves the balance of performance and benefit through molecular design, and its innovative applications in the fields of polymer material modification, electronic packaging and environmental protection coatings continue to promote the technological upgrading and sustainable development of related industries.

Contact Us

Product Package picture:

Related References:

chemicalbook-Trimethylolpropane Trimethacrylate

Trimethylolpropane Trimethacrylate Manufacturer

Contact Us

As an experienced Trimethylolpropane Trimethacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Trimethylolpropane Trimethacrylate CAS 3290-92-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.