Trimethylolpropane Triacrylate CAS 15625-89-5

Factory wholesale Trimethylolpropane Triacrylate CAS 15625-89-5

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Trimethylolpropane Triacrylate

CAS: 15625-89-5

MOQ: 1KG

Directory Guidance on Trimethylolpropane Triacrylate

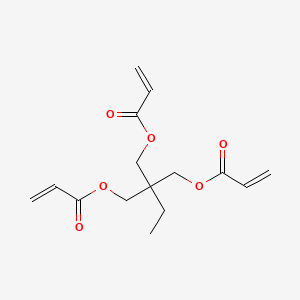

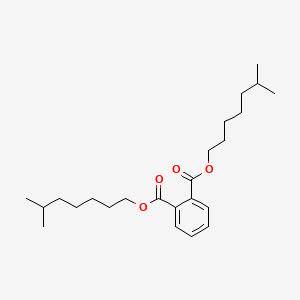

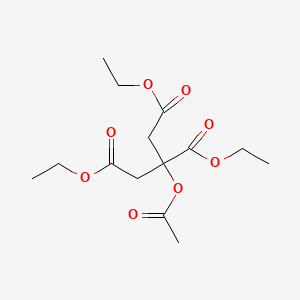

Chemical Structure

Basic Info:

| Melting point | -66°C |

| Boiling point | >200°C |

| density | 1.1 g/mL at 25 °C (lit.) |

| vapor density | >1 (vs air) |

| vapor pressure | <0.01 mm Hg ( 20 °C) |

| refractive index | n20/D 1.474(lit.) |

| Fp | >230 °F |

Product Introduction:

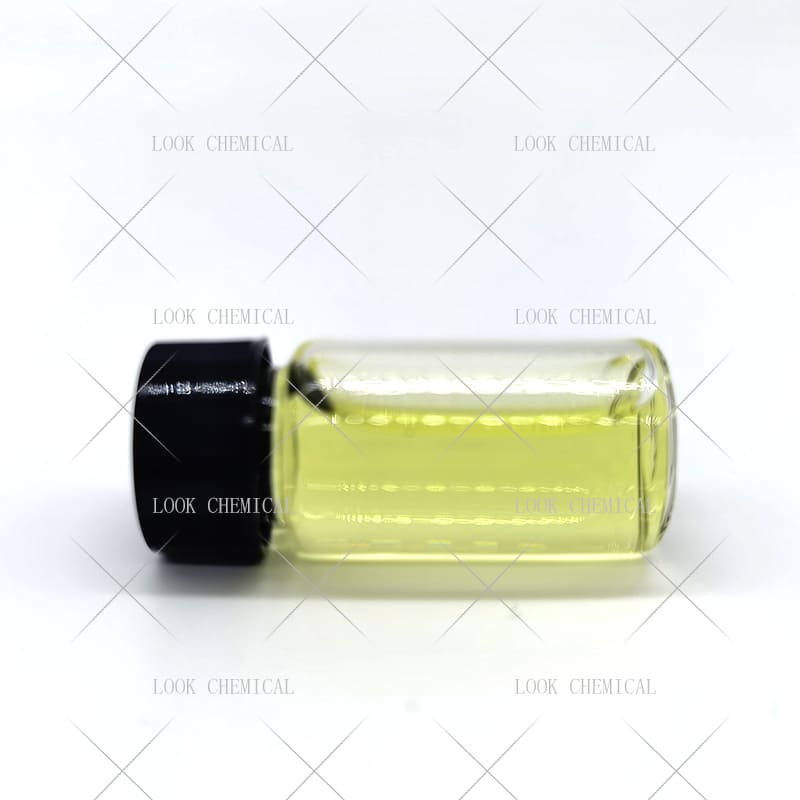

Trimethylolpropane Triacrylate is an integral three-functional monomer with unique chemical structure and excellent properties, featuring colorless or yellow transparent liquid, almost insoluble in water yet soluble in organic solvents such as aromatic hydrocarbons. It has the formula C15H20O6 with an approximate molecular weight of 296.32, high boiling point but low vapor pressure; density 1.06g/ml at 25 degrees Celsius and refractive index of about 1.472.

Trimethylolpropane Triacrylate’s chemical properties are extremely dynamic due to the three acrylate groups present within its molecules. These three acrylate groups give Trimethylolpropane Triacrylate properties of high reactivity and rapid curing that make it an excellent candidate for radiation curing applications, including ultraviolet or electron beam irradiation to form hard and scratch-resistant films with good solvent resistance and mechanical properties – with relatively low viscosity that enables easy processing and application when mixed with other monomers for easier radiation curing applications.

Trimethylolpropane Triacrylate can be found in many fields, from coatings, inks, adhesives, electronic materials and rubber production. Within these industries it has wide-ranging applications, spanning the coatings industry (using UV curable coatings with improved hardness, wear resistance and adhesion properties), ink production (light curing inks to improve printing quality and reduce drying times) as well as rubber crosslinking agent to increase its aging resistance, corrosion resistance as well as hardness/heat resistance properties in rubber products produced using rubber products vulcanization techniques as well as rubber crosslinking agent used as part of rubber crosslinking processes vulcanization agents).

Although Trimethylolpropane Triacrylate offers many benefits, its use must also be undertaken with care to avoid skin and eye irritation during operation. When operating, use appropriate safety measures like wearing protective gloves and goggles to avoid direct skin or eye contact; should this occur, flush immediately with plenty of water until medical assistance can be sought if necessary.

Nature and Specifications:

| Item | Specification |

| Product Name | Trimethylolpropane Triacrylate |

| CAS No. | 15625-89-5 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Refrigerator |

| pka | 0[at 20 ℃] |

| form | Liquid |

| color | Colorless to Light yellow to Light orange |

| Specific Gravity | 1.1 |

| Water Solubility | Miscible with water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Trimethylolpropane Triacrylate is widely utilized within the coatings industry for UV-curable coating production. Containing three acrylate double bonds that rapidly crosslink upon exposure to ultraviolet radiation, it forms an interlink network structure with high cross-link density. This results in coating films with high hardness, gloss levels and scratch resistance – while drastically shortening curing times and increasing production efficiency. Trimethylolpropane Triacrylate can also be used to modify coatings such as epoxy acrylates, polyurethanes and unsaturated polyesters to increase bonding strength and quality through curing crosslinking techniques like electron beam irradiation or heating – making it suitable for wood coatings, PVC coatings and metal finishes. As such it has become widely utilized across numerous fields including wood finishes, PVC finishes, metal coatings and many more.

Trimethylolpropane Triacrylate has found widespread application in ink production. Primarily utilized for light curing applications due to its fast curing rate and high cross-linking density characteristics, Trimethylolpropane Triacrylate helps produce light curing ink with quick drying times that helps reduce solvent volatilization while improving printing quality and production efficiencies. Ideal for offset printing, flexographic printing and screen printing processes as it has good adhesion and wear resistance on various substrates such as paper plastic and metal surfaces while 3D printing inks provide enhanced mechanical strength and durability of printed parts created using 3D printing inks containing Trimethylolpropane Triacrylate.

Trimethylolpropane Triacrylate adhesives are widely used to improve bond strength and chemical resistance, thanks to their high cross-linking density network structure that enhances cohesion of adhesive. Furthermore, this adhesive boasts exceptional results when bonding metals, glass, ceramics, etc. Additionally, Trimethylolpropane Triacrylate can also be used to produce UV light curing adhesive that has fast curing speed, strong bond strength, weatherproof properties as well as widespread applications within electronic equipment, auto parts manufacturing as well as building decoration fields such as building decoration – widely utilized throughout electronics, auto parts manufacturing industries as well as building decoration industries.

Trimethylolpropane Triacrylate holds great potential in electronic materials manufacturing. It is commonly used as an insulation material for microelectronic products like packaging materials for integrated circuits and printed circuit boards, among other applications. Polymer films possess excellent heat resistance, radiation resistance, moisture resistance, and electrical insulation properties that can significantly enhance reliability and service life of electronic products. Additionally, it can also be used to produce high-performance ion exchange resins with superior characteristics for wastewater treatment and electronics ion exchange processes in electronics industry applications, including pollution resistance, high strength, heat resistance and corrosion resistance. This resin has proven useful as an economical and sustainable ion exchange option.

Trimethylolpropane Triacrylate is widely utilized within the rubber industry as a crosslinker and co-vulcanizing agent, and can help improve hardness, heat resistance and aging resistance of rubber products. For instance, PVC cable materials using radiation crosslinking with this substance can increase their temperature resistance level up to over 105 deg C with its addition. Furthermore, TPT can also be used to create thermoplastic polyurethane elastomers, which combine elastic properties of rubber with processing properties similar to plastic; they find use within automotive parts, shoe materials as wire and cable sheaths among many other industries.

Trimethylolpropane Triacrylate is a versatile monomer with outstanding performance and many significant advantages. First, its three acrylate double bonds enable rapid cross-linking under UV or electron beam (EB) radiation, creating a network structure with high cross-link density and providing for fast curing times in coatings, inks and adhesives production; this feature enhances production efficiency while shortening processing times for industrial production processes and offering great convenience to industry production processes.

Trimethylolpropane Triacrylate stands out among fast curing materials by also possessing excellent physical properties. Its cross-linked density polymer network offers high hardness, gloss and wear resistance, along with scratch resistance. Curing film can meet the requirements for high hardness and wear resistance in surface coating, making it suitable for use in high performance protection applications. Additionally, polymer films made of Trimethylolpropane Triacrylate boast both good heat and chemical resistance, providing stable performance even under harsh environments. When applied to rubber and plastic products it can greatly increase heat resistance as well as solvent resistance; further expanding its application range.

Trimethylolpropane Triacrylate boasts low viscosity, making it suitable for dispersion and processing in coatings and inks. When compared with monofunctional and bifunctional monomers, its lower viscosity characteristics allow it to effectively reduce temperature, time, energy usage and costs associated with production efficiency and energy consumption. Furthermore, Trimethylolpropane Triacrylate offers cost-effective solutions in cost-sensitive applications like paper polish and wood paint that meet market demands for high performance materials.

Trimethylolpropane Triacrylate’s versatility is one of its primary assets. Not only can it excel in coatings, inks and adhesives applications but it can also find uses in rubber products as crosslinking agents or co-vulcanizing agents to increase mechanical strength and aging resistance; among its wide applications in rubber products alone, plastics, electronic materials and electronic materials among others; its applications can include rubber products, plastics as well as rubber products containing crosslinking agents to improve mechanical strength/aging resistance/aging resistance of products as well as high performance ion exchange resins/thermoplastic polyurethane elastomers showing high application value!

Contact Us

Product Package picture:

Related References:

chemicalbook-Trimethylolpropane Triacrylate

Trimethylolpropane Triacrylate Manufacturer

Contact Us

As an experienced Trimethylolpropane Triacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Trimethylolpropane Triacrylate CAS 15625-89-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.