Triethylene Glycol Dimethyl Ether CAS 112-49-2

Factory wholesale Triethylene Glycol Dimethyl Ether CAS 112-49-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Triethylene Glycol Dimethyl Ether

CAS: 112-49-2

MOQ: 1KG

Directory Guidance on Triethylene Glycol Dimethyl Ether

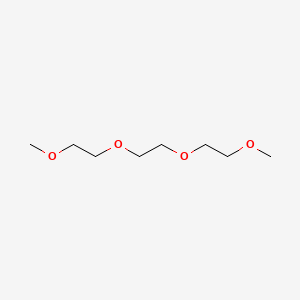

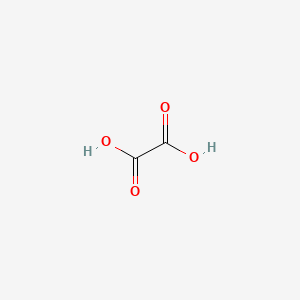

Chemical Structure

Basic Info:

| Melting Point | −45 °C(lit.) |

| Boiling Point | 216 °C(lit.) |

| Density | 0.986 g/mL at 25 °C(lit.) |

| Vapor Density | >4.7 (vs air) |

Triethylene Glycol Dimethyl Ether Introduction:

Triethylene Glycol Dimethyl Ether, TGME or TEGDME for short, has the chemical formula CH3O(CH2CH2O)3CH3. It is a key member of the glycol ether solvent family and is a relatively long-chain and outstanding variety in the polyglyme series (Glymes).

As a colorless, transparent, slightly sweet, low-volatility liquid, its molecular structure contains two methoxy end groups and multiple hydrophilic ethoxy (-CH2CH2O-) units. This unique molecular conformation endows it with a series of outstanding physical and chemical properties.

In terms of physical properties, Triethylene Glycol Dimethyl Ether exhibits impressive solvent capabilities. It has a boiling point of up to 285°C (normal pressure), making it of key value in high-temperature processes. Its freezing point is about -45°C, which means that it can maintain liquid operation convenience over a fairly wide range of industrial operating temperatures.

The mainstream process for the synthesis and production of Triethylene Glycol Dimethyl Ether is usually the monomethyl ether of ethylene glycol or diethylene glycol in the presence of an alkaline catalyst (such as sodium hydroxide or sodium methoxide) and a step-by-step ring-opening addition reaction with ethylene oxide (EO). Its selectivity and yield can be optimized by precise control of the catalyst, reactant ratio, temperature and feeding method.

Although Triethylene Glycol Dimethyl Ether has relatively low toxicity, as an organic solvent, it still has a certain degree of irritation to the eyes, skin and respiratory tract during actual operation in industrial sites. Therefore, it is crucial to provide sufficient and effective ventilation conditions to avoid the accumulation of its vapor or aerosol in the operation area. Operators must wear standard personal protective equipment such as chemical goggles and compliant impermeable protective gloves to ensure that the risk of physical exposure is minimized.

Given the low vapor pressure of Triethylene Glycol Dimethyl Ether (typically < 0.1 mmHg, 20°C), it has a lower risk of emitting volatile organic compounds (VOCs) to the environment under normal use conditions, reflecting its potential environmental advantages in specific application areas. However, in specific applications such as wastewater systems, its biodegradability and ecotoxicity data still need to be considered to meet increasingly stringent environmental compliance requirements. Understanding and respecting the intrinsic physicochemical properties of this compound and adhering to standard operating procedures (SOPs) are the core prerequisites for its safe and efficient application.

Nature and Specifications:

| Item | Specification |

| Product Name | Triethylene Glycol Dimethyl Ether |

| CAS No. | 112-49-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Vapor Pressure | 1.2 hPa (20 °C) |

| Refractive Index | n20/D 1.423(lit.) |

| Fp | 231 °F |

| Storage Temp. | Store below +30°C. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Triethylene Glycol Dimethyl Ether

In the field of lithium-based batteries, the core role of Triethylene Glycol Dimethyl Ether is reflected in its role as the main solvent component of the electrolyte. It has good solubility for various lithium salts, such as the most common lithium hexafluorophosphate (LiPF6), lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) and new lithium salts, ensuring the formation of an electrolyte system with the required concentration and sufficient ionic conductivity. Its extremely high dielectric constant (about ~7.5, 25°C) can effectively weaken the Coulomb attraction between anions and cations in the salt, and promote the dissociation of lithium salts to generate sufficient effective carriers (Li+ ions).

At the same time, the relatively low viscosity characteristics contribute to the rapid migration and diffusion of Li+ ions in the electrolyte body. More importantly, its lower molecular orbital energy level gives it a relatively wider electrochemical stability window (relative to the lithium potential, the negative electrode is stable to about 1.5V or less, and the positive electrode is stable to 4.5V or more), and its chemical compatibility with high-voltage positive electrode materials and active lithium metal negative electrodes is better than many traditional carbonate solvents.

This wide electrochemical window is essential for the development of high energy density batteries. Its low freezing point and good thermal stability over a wide temperature range are conducive to the expansion of high and low temperature performance and working safety of the battery. In addition, due to its extremely low vapor pressure, it helps to reduce the risk of gas expansion in the battery system at high temperatures, thereby extending the battery life.

Triethylene Glycol Dimethyl Ether is also an extremely important, versatile, highly polar aprotic reaction solvent in the pharmaceutical industry and fine organic synthesis. Its high boiling point makes it an ideal choice for reactions that need to be carried out at high temperatures for a long time (such as catalytic hydrogenation, various coupling reactions C-C, C-N bond construction, nitration, sulfonation and other electrophilic reactions). It ensures a uniform reaction environment while avoiding excessive evaporation loss of the solvent.

As an inert (non-reaction) highly polar solvent, it can well dissolve a variety of reactants (including polar intermediates and certain salts), effectively stabilize charged reaction intermediates (such as carbon cations), and help dissipate the reaction heat in a timely manner. In complex multi-step organic synthesis, especially conditions that require the participation of strong alkaline or strong nucleophilic reagents (such as Grignard reagent reactions, alkyl lithium reactions, and some organic metal catalytic reactions), its non-protonic nature avoids unnecessary proton transfer side reactions with these sensitive reagents.

In the field of gas treatment, Triethylene Glycol Dimethyl Ether has also found key applications. Due to its good miscibility with water and its certain solubility for specific organic compounds such as alcohols, aldehydes, and acids, as well as its low volatility and insolubility in natural gas components, it is very suitable for the removal or deep drying (dehydration) of acidic gases (such as CO2 and H2S).

In a typical physical absorption gas purification process, Triethylene Glycol Dimethyl Ether or a mixed solvent formula containing this component is used as an absorption solvent in the absorption tower to countercurrently contact with the gas to be treated, and selectively absorbs and separates acidic gas impurities or moisture with its physical solubility. Solvent regeneration by reducing pressure and raising temperature can achieve its efficient recycling. Its low vapor pressure characteristics effectively reduce the vapor phase entrainment loss (carrying loss) of the solvent during the absorption operation, which is its outstanding advantage in gas purification applications.

It also plays a supporting role in the synthesis process of high value-added materials. For example, in the preparation of polyamic acid solution, the precursor of high-performance polymers such as polyimide, Triethylene Glycol Dimethyl Ether can be used as a polymerization solvent or a dissolving spinning solvent. Its high solubility and thermal stability are the guarantee of process success. When constructing complex catalytic systems, it can be used as a co-solvent or diluent for transition metal complexes, playing a role in regulating the reaction environment during catalytic synthesis.

In the field of special coatings, inks and adhesives, Triethylene Glycol Dimethyl Ether is also one of the options to be considered in formulations that require high boiling point solvents to ensure uniform film drying or adjust viscosity. In addition, it also has mature application practices as a solvent, diluent or sample extraction solvent in liquid chromatography (LC) or gas chromatography (GC) analysis. This wide penetration fully reflects the strong technical value that a well-designed molecular platform can show when it spans multiple industries.

The Advantages Of Triethylene Glycol Dimethyl Ether

The outstanding and broad dissolution ability constitutes its core competitiveness. Triethylene Glycol Dimethyl Ether has an extraordinary solubility range: it can not only be completely miscible with water, but also establish reliable compatibility with most common alcohols (methanol, ethanol), ketones (acetone), esters (ethyl acetate), chlorinated hydrocarbons (dichloromethane, chloroform), aromatic hydrocarbons (benzene, toluene), etc. More importantly, it exhibits excellent solubility for various inorganic and organic electrolytes, such as lithium salts, quaternary ammonium salts, and metal complexes,

Extraordinary thermochemical and electrochemical stability are the cornerstone of its foothold in high demand scenarios. At high temperatures, Triethylene Glycol Dimethyl Ether molecules can maintain good resistance to thermal degradation. Its thermal decomposition initiation temperature is usually much higher than 250 ℃, and it can withstand high temperatures of around 300 ℃ in an inert atmosphere, making it suitable for harsh environments that require high-temperature synthesis, separation, or energy storage operations.

In terms of chemical stability, Triethylene Glycol Dimethyl Ether has good tolerance to many common weak acids and weak bases. Its molecules lack sites that are easily oxidized (such as unsaturated bonds or active hydrogen atoms), are not prone to common oxidation reactions, and are usually only slowly destroyed under strong oxidizing conditions. Its chemical compatibility with various reducing environments (such as catalytic hydrogenation) and Lewis acid catalytic systems is generally better than many common aprotic solvents (such as tetrahydrofuran).

Excellent electrochemical properties are the determining factor for Triethylene Glycol Dimethyl Ether core position in energy storage. Its high dielectric constant (about 7.5 to 8.0, 25°C) can effectively overcome the strong Coulomb attraction between the anions and cations of the lithium salt dissolved therein, and promote the dissociation and separation of more Li⁺ and anions. This directly improves the bulk ionic conductivity of the electrolyte at the technical level, allowing the battery to operate at a higher rate and a wider temperature range.

At the same time, multiple ether oxygen atoms inTriethylene Glycol Dimethyl Ether molecular structure can form a weak coordination effect with Li⁺ ions, and this moderate effect reduces the Li⁺ ion migration energy barrier (reducing the desolvation energy). In addition, its low viscosity (~4.8 mPa·s, 25°C) facilitates the rapid migration and diffusion of carriers (Li⁺) in liquid media. These properties work together to make the electrolyte solution prepared by it have a sufficiently high and practical ionic conductivity (usually up to 10^{-3} S/cm).

Contact Us

Product Package picture:

Related References:

Chemicalbook-Triethylene Glycol Dimethyl Ether

Triethylene Glycol Dimethyl Ether Manufacturer

Contact Us

As an experienced Triethylene Glycol Dimethyl Ether manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Triethylene Glycol Dimethyl Ether CAS 112-49-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.