Tri-N-Hexyl Aluminum CAS 1116-73-0

Factory wholesale Tri-N-Hexyl Aluminum CAS 1116-73-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Tri-N-Hexyl Aluminum

CAS: 1116-73-0

MOQ: 1KG

Directory Guidance on Tri-N-Hexyl Aluminum

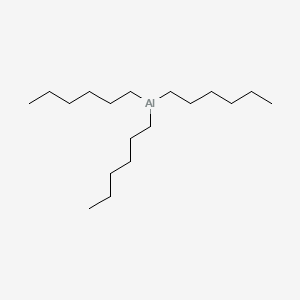

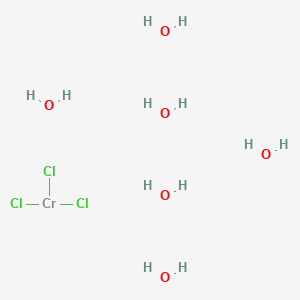

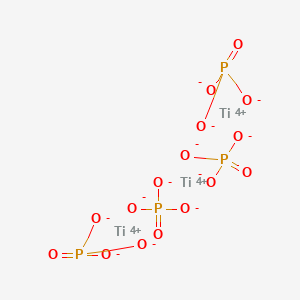

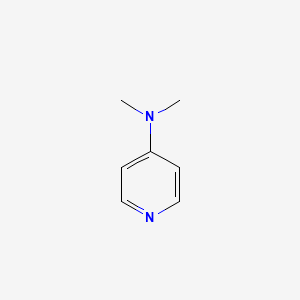

Chemical Structure

Basic Info:

| Melting point | -76.9°C |

| Boiling point | 105 °C(Press: 0.001 Torr) |

| density | 0.686 |

| vapor pressure | 0Pa at 25℃ |

| storage temp. | Flammables + water-Freezer (-20°C)e area |

Product Introduction:

Tri-N-Hexyl Aluminum, as an important member in the field of organometallic compounds, has occupied an irreplaceable position in materials science and the chemical industry since its industrial production in the middle of the 20th century. Its chemical formula is Al(C₂H₅)₃, which is formed by covalent bonds between aluminum atoms and three ethyl groups. It appears as a colorless and transparent liquid at room temperature and has strong volatility and a pungent odor. From the perspective of molecular structure analysis, aluminum atoms are in an electron-deficient state, which makes them exhibit extremely high Lewis acidity. This characteristic lays the foundation for their core functions as catalysts and reducing agents.

In terms of physical properties, Tri-N-Hexyl Aluminum has a low density. Compared with water and some common organic solvents, it can easily float on the liquid surface. This feature has practical application value in certain specific chemical process flows, and is convenient for layering and separation. Its boiling point is relatively low, about 190℃ at normal pressure, which makes it easier to separate and purify it in some experiments and industrial production processes that require reduced pressure distillation or control of reaction temperature, avoiding problems such as side reactions and material decomposition caused by high temperature.

In terms of the preparation process, the Grignard reaction method of aluminum powder and halogenated ethane is mainly adopted in industry. By precisely controlling the reaction temperature and pressure gradient, industrial production with a product purity exceeding 99.5% can be achieved. Molecular sieve adsorption and low-temperature distillation technologies are widely introduced in modern processes to effectively separate the by-product Tri-N-Hexyl Aluminum chloride, reducing the impurity content to the level of one part per million. From the perspective of chemical kinetics, the synthesis reaction of Tri-N-Hexyl Aluminum belongs to a typical nucleophilic substitution mechanism.

In addition, Tri-N-Hexyl Aluminum requires special attention to its high sensitivity to air and moisture during storage and transportation. It is highly prone to react with oxygen and water vapor in the air, causing it to deteriorate and decompose, producing some useless or even harmful substances. Therefore, it is usually sealed and stored in a dry, oxygen free environment, such as a container filled with inert gas, and special packaging materials are used to isolate the outside air and moisture. Corresponding protective measures should also be taken during transportation to avoid product loss caused by changes in environmental factors.

Nature and Specifications:

| Item | Specification |

| Product Name | Tri-N-Hexyl Aluminum |

| CAS No. | 1116-73-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| vapor pressure | 0Pa at 25℃ |

| storage temp. | Flammables + water-Freezer (-20°C)e area |

| form | Liquid |

| color | Clear colorless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the field of organic synthesis, Tri-N-Hexyl Aluminum plays an extremely important role. These alkoxy aluminum compounds can further serve as intermediates to participate in other organic synthesis reactions, being used to synthesize organic materials with special properties, such as certain high-performance plastic additives or drug intermediates, etc. When synthesizing some organic molecules with complex structures, Tri-N-Hexyl Aluminum can be used as an effective alkylation reagent. Through the synergistic effect with other organometallic reagents or organic halides, the n-hexyl group is introduced into the target organic molecule, thereby changing its physicochemical properties. Such as melting point, boiling point, solubility and biological activity, etc.

Tri-N-Hexyl Aluminum is used in polymer materials mainly as a catalyst or additive in polymerization reactions or to improve other catalysts’ activity. Synthesis of polyolefins such as polyethylene and polypropylene may include using transition metal catalysts (Ziegler-Natta catalysts) to increase activity and selectivity of their catalysts. By manipulating the ratio between Tri-N-Hexyl Aluminum, transition metal catalyst, and reaction conditions, parameters like molecular weight distribution and crystallinity of polyolefin polymer can be adjusted for specific application scenarios to produce products with tailored properties to match performance requirements of products made using Tri-N-Hexyl Aluminum. Assemblage materials such as packaging materials, pipes, films and automotive parts. Tri-N-Hexyl Aluminum can also be used to synthesize polymers with specific properties, including flame retardancy, antistatic properties or high-temperature resistance. By adding Tri-N-Hexyl Aluminum during polymerization reaction process, special functional aluminum groups will be introduced into polymer chains resulting in new performance characteristics for these polymers.

Tri-N-Hexyl Aluminum can be utilized both alone or as an additive catalyst in other chemical reactions, beyond being utilized alongside transition metal catalysts for polymer synthesis. As part of certain organic synthesis reactions, it can catalyze condensation reactions between alcohols and aldehydes or ketones resulting in condensation products. Condensation products find use in the production of fragrances, dyes and pharmaceutical intermediates. Tri-N-Hexyl Aluminum can also be used to modify existing catalyst systems, improving their stability and catalytic activity, prolonging service life, lowering cost/energy consumption during chemical reactions, and opening up vast application prospects in fields such as fine chemicals, petrochemicals and the creation of new materials.

Tri-N-Hexyl Aluminum has long been recognized as an integral organoaluminum compound in chemical research. Chemists utilize it as an ideal model compound to explore organometallic chemical reactions. Tri-N-Hexyl Aluminum can be utilized to gain insight into its reactivity, coordination chemistry and reaction kinetics as organometallic aluminum compounds can provide insight into their reactions with various compounds – thus providing theoretical support for creating new organometallic catalysts and synthetic methods.

In terms of process compatibility, Tri-N-Hexyl Aluminum exhibits unique solvent adaptability. and it has good compatibility with most organic metal catalysts, which makes it possible to construct a multi-component catalytic system. In a continuous flow reactor, the viscosity of Tri-N-Hexyl Aluminum solution is only 0.89 mPa·s (30℃), and its flow characteristics are better than those of similar aluminum compounds, which is conducive to precise feeding control. From an industrial perspective, its liquid characteristics simplify the storage and metering links, and the feeding accuracy can be controlled within ±0.5% with the help of an automated control system, which is crucial to maintaining the stability of catalyst activity.

In terms of economy, the large-scale production technology of Tri-N-Hexyl Aluminum is becoming more and more mature. After adopting the continuous flow synthesis process, the annual production capacity of a single line has exceeded 5,000 tons, and the unit energy consumption is reduced by 42% compared with the traditional batch method. In terms of raw material utilization, the conversion rate of aluminum powder in modern processes can reach 98.7%, and the by-products can be re-entered into the production process after recycling treatment, and the overall material balance coefficient reaches 0.993. This efficient production model has caused the market price of Tri-N-Hexyl Aluminum to drop by about 35% in the past decade, but the product purity has increased from 99.0% to 99.9%, and the cost-effectiveness advantage continues to expand.

In terms of environmental protection and safety, the green improvement of Tri-N-Hexyl Aluminum has made breakthrough progress. The application of new passivation technology has extended the self-ignition delay time after contact with air to 120 seconds, providing a critical window period for emergency disposal. In the wastewater treatment link, a phosphate precipitation-membrane separation combined process has been developed to reduce the residual aluminum ion content to below 0.1 mg/L, fully meeting the requirements of the “Comprehensive Wastewater Discharge Standard”. Life cycle assessment (LCA) data shows that the carbon footprint of the production process of each ton of Tri-N-Hexyl Aluminum is 2.3 tons of CO2 equivalent, a decrease of 28% from the 2010 baseline value, mainly due to the increase in the proportion of clean energy use and energy efficiency improvements brought about by process optimization.

Contact Us

Product Package picture:

Related References:

chemicalbook-Tri-N-Hexyl Aluminum

Tri-N-Hexyl Aluminum Manufacturer

Contact Us

As an experienced Tri-N-Hexyl Aluminum manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Tri-N-Hexyl Aluminum CAS 1116-73-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.