Thionyl Chloride CAS 7719-09-7

Factory wholesale Thionyl Chloride CAS 7719-09-7

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Thionyl Chloride

CAS: 7719-09-7

MOQ: 1KG

Directory Guidance on Thionyl Chloride

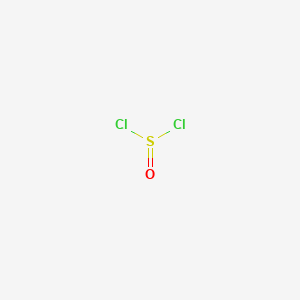

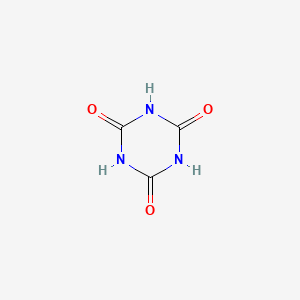

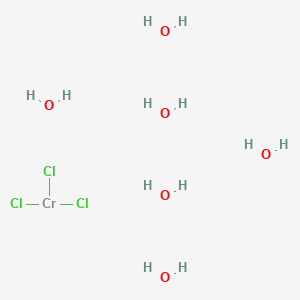

Chemical Structure

Basic Info:

| Melting point | -105 °C |

| Boiling point | 79 °C(lit.) |

| density | 1.64 g/mL at 20 °C |

| vapor density | 4.1 (vs air) |

| vapor pressure | 97 mm Hg ( 20 °C) |

| refractive index | n20/D 1.518(lit.) |

Product Introduction:

Thionyl Chloride (chemical formula SOCl₂) is a colorless to pale yellow liquid with a strong pungent odor. It is volatile and hydrolyzes violently in water to produce hydrogen chloride (HCl) and sulfur dioxide (SO₂). Its molecular weight is 118.97, boiling point is about 79°C, density is 1.631 g/cm³, and it is miscible with ethers, alkanes and halogenated hydrocarbons at room temperature, but reacts violently with water and protic solvents (such as DMF, DMSO). As an important fine chemical raw material, Thionyl Chloride is highly active in chemical properties and has both chlorination and dehydration functions. Therefore, it is often used as a chlorinating agent, dehydrating agent or catalyst in organic synthesis.

From the perspective of preparation technology, the industrial production of Thionyl Chloride mainly adopts the chlorosulfonic acid method, co-production method, sulfur dioxide gas phase method and sulfur trioxide gas phase method. The early chlorosulfonic acid method has been gradually eliminated due to its low efficiency and high pollution. Although the co-production method has low investment costs, the market demand for the by-product phosphorus oxychloride is limited, and the product is prone to contain impurities.

In terms of safety and environmental protection, the strong corrosiveness and toxicity of Thionyl Chloride impose strict requirements on production, HCl and SO₂ produced by hydrolysis need to be absorbed by the tail gas treatment system to avoid environmental pollution. In addition, Thionyl Chloride may decompose to generate Cl₂, SO₂ and S₂Cl₂ at high temperature (>140°C) or in the presence of metal ions (such as iron and zinc). Therefore, it needs to be stored away from light, dry, and away from metal impurities.

The global Thionyl Chloride production capacity is highly concentrated. China is the main producer, and leading companies such as Shandong Kaisheng New Materials Co., Ltd. have occupied a dominant position in the market through technological innovation. The company adopts a gas-phase continuous synthesis process to achieve sulfur dioxide recycling, greatly reducing raw material consumption and “three wastes” emissions. The product purity and production capacity are at the leading level in the industry. The current global Thionyl Chloride annual production capacity is about 480,000 tons, of which China accounts for more than 60%. Downstream demand covers pesticides, medicines, dyes, new energy and other fields, and the market prospects are broad.

Nature and Specifications:

| Item | Specification |

| Product Name | Thionyl Chloride |

| CAS No. | 7719-09-7 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 105°C |

| storage temp. | Store at RT. |

| solubility | Miscible with toluene, chloroform, benzene, carbon tetrachloride and diethyl ether. |

| form | Liquid |

| color | ≤50(APHA) |

| Odor | Characteristic, pungent odor |

| Water Solubility | REACTS |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the traditional chemical industry, the core applications of Thionyl Chloride include chlorination reaction, preparation of acyl chloride and dehydration reaction. As an efficient chlorination agent, it can convert alcohols into chlorinated hydrocarbons. For example, the synthesis of pesticide intermediates (such as deltamethrin, cypermethrin) and pharmaceutical raw materials (such as ciprofloxacin, vitamin E) depends on this reaction path. In addition, the property of Thionyl Chloride to react with carboxylic acid to generate acyl chloride is widely used in the preparation of high value-added products, such as polyester monomers terephthaloyl chloride and isophthaloyl chloride, the latter of which is a key raw material for the production of high-performance aramid fibers.

The pesticide industry is one of the important downstream markets of Thionyl Chloride, involving the synthesis of pyrethroid insecticides, fungicides and herbicides. For example, the production of intermediates of pesticides such as propargite and endosulfan requires the chlorination of Thionyl Chloride to achieve functional group transformation. The pharmaceutical field relies on it to prepare antibiotics, anti-tumor drugs and cardiovascular drugs. For example, the anti-inflammatory drug ciprofloxacin and the lipid-lowering drug fluvastatin both require it as a chlorinating agent. In the dye industry, the synthesis of the reactive turquoise series of dyes is also inseparable from its chlorination modification of hydroxyl groups.

In recent years, breakthroughs in the fields of new energy and new materials have opened up new demands for Thionyl Chloride. the synthesis of the new lithium salt lithium bis(fluorosulfonyl)imide (LiFSI) requires it as a raw material, and LiFSI is regarded as the core component of the next generation of electrolytes due to its excellent conductivity and thermal stability, and the market demand is growing significantly.

Thionyl Chloride also shows potential in the field of environmental protection. For example, in the process of leaching germanium from germanium-rich lignite, it achieves efficient extraction of germanium (leaching rate > 95%) by replacing the hydroxyl groups in lignite, while retaining the lignite structure for energy recovery and realizing comprehensive resource utilization.

Facing the “dual carbon” goal, the value of Thionyl Chloride in green chemistry is further highlighted. As a dehydrating agent, it participates in the ring-closing reaction of polymer materials to reduce the generation of by-products; in the synthesis of high-temperature resistant engineering plastics such as polyetherketoneketone (PEKK), it improves material performance by catalyzing polycondensation reactions. With the growing demand for high-performance materials in aerospace, 5G communications and other fields, the high-end application of Thionyl Chloride will continue to expand.

The core competitiveness of Thionyl Chloride comes from the continuous optimization of its production process and the synergy of the industrial chain. Taking the gas phase method as an example, the synthesis and refining processes are integrated through reactive distillation technology, which not only shortens the production cycle, but also makes the product purity reach more than 99.8%, far exceeding the industry standard. Some leading companies reduce the cost of raw materials by more than 30% through the recycling of by-product sulfur dioxide (recovery rate>95%), while reducing waste gas emissions, meeting the requirements of green manufacturing.

In terms of cost control, integrated layout is a key strategy for industry-leading companies. Self-produced Thionyl Chloride provides stable and low-cost raw materials for downstream products (such as aramid monomers and acyl chloride derivatives), avoiding the price fluctuation risk of external procurement. Taking isophthaloyl chloride as an example, Thionyl Chloride accounts for more than 60% of its production cost, and the self-supply model can significantly improve the profit margin. In addition, the recycling of by-product hydrochloric acid further reduces the cost of environmental protection treatment, forming a closed-loop economy of “resources-products-renewable resources”.

The technical research and development barriers are reflected in the preparation of high-purity products and the development of new applications. Trace impurities (such as S₂Cl₂) in Thionyl Chloride may affect the efficiency of downstream reactions. Advanced companies control the impurity content below 0.004% through distillation tower optimization and catalyst modification. In the field of new energy, some companies have developed exclusive purification processes to achieve the international leading level of electrochemical performance of LiFSI in view of the high purity requirements of Thionyl Chloride in LiFSI synthesis.

Innovation in environmental protection and safety technology has also become a watershed in the industry. Through closed production systems and automated control, the risk of manual contact is reduced; multi-stage absorption devices for hydrolysis tail gas (such as alkali spraying and activated carbon adsorption) ensure that emissions meet standards. Some companies also convert the decomposition product S₂Cl₂ into sulfur for reuse, realizing the resource utilization of hazardous waste and reducing environmental risks.

From the perspective of the market structure, the industry concentration continues to increase. Leading companies dominate the high-end market with scale effects and patent barriers. For example, the core equipment design and catalyst formulation of the gas phase process have formed a technical monopoly, and new entrants need to break through bottlenecks such as reactor design and heat recovery. In addition, downstream customers’ high requirements for product consistency (such as pharmaceutical-grade Thionyl Chloride must comply with GMP standards) further consolidate the competitive advantages of leading companies.

In the future, with the explosion of demand for new energy and new materials, the Thionyl Chloride industry will develop in the direction of high purity and specialization. Companies need to continue to invest in research and development to expand their applications in cutting-edge fields such as solid-state battery electrolytes and biodegradable materials, while improving production efficiency and safety through intelligent transformation to consolidate their core position in the global supply chain.

Contact Us

Product Package picture:

Related References:

chemicalbook-Thionyl Chloride

Thionyl Chloride Manufacturer

Contact Us

As an experienced Thionyl Chloride manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Thionyl Chloride CAS 7719-09-7 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.