Tetramethylthiuram Disulfide CAS 137-26-8

Factory wholesale Tetramethylthiuram Disulfide CAS 137-26-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Tetramethylthiuram Disulfide

CAS: 137-26-8

MOQ: 1KG

Directory Guidance on Tetramethylthiuram Disulfide

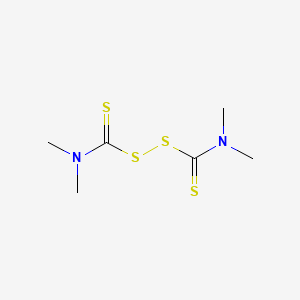

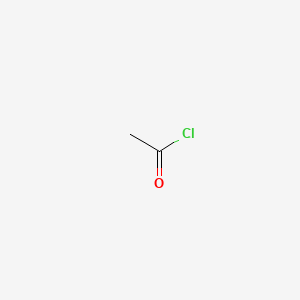

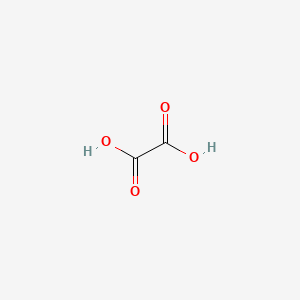

Chemical Structure

Basic Info:

| Melting Point | 156-158 °C(lit.) |

| Boiling Point | 129 °C (20 mmHg) |

| Density | 1.43 |

| Vapor Pressure | 8 x 10-6 mmHg at 20 °C (NIOSH, 1997) |

Tetramethylthiuram Disulfide Introduction:

Tetramethylthiuram Disulfide (TMTD) is an extremely important and long-standing thiuram vulcanization accelerator in the rubber industry. Its molecular structure is (C₂H₆)₂NCS₂S₂. It usually appears as white to off-white crystalline powder or flakes at room temperature, with a slight special smell.

From a chemical point of view, Tetramethylthiuram Disulfide belongs to the category of super accelerators. Its mechanism of action in the vulcanization reaction is quite complex and efficient. Under the vulcanization temperature conditions, the S-S bonds in the product molecules are prone to breakage, releasing highly reactive free radicals, and more importantly, decomposition to produce free sulfur or sulfur-containing free radical intermediates.

These active substances can quickly trigger the reaction sites on the rubber macromolecular chain, prompting the adjacent macromolecular chains to form a three-dimensional network structure through sulfur bridges, that is, to achieve vulcanization crosslinking. This process significantly reduces the activation energy required for the vulcanization reaction and greatly increases the vulcanization rate.

Tetramethylthiuram Disulfide exhibits extremely significant dual effects of “promotion” and “activation” in the vulcanization system. Its high efficiency is reflected in that it can not only provide active sulfur itself to accelerate the process of sulfur vulcanization alone, but also effectively activate other types of accelerators (especially sulfonamides such as CZ, NS, etc.).

When Tetramethylthiuram Disulfide is used in conjunction with sulfonamide accelerators, it can quickly decompose and catalyze sulfonamide to release active groups, thereby initiating an explosive vulcanization reaction, achieving faster vulcanization start and higher crosslinking density. This strong activation property makes it an indispensable component in many high-performance, fast-vulcanization formulas.

As a multifunctional compounding agent, the value of Tetramethylthiuram Disulfide is also reflected in its ability to partially or completely replace traditional sulfur as a vulcanizing agent (the so-called “sulfur-free vulcanization” or “effective vulcanization system”), in which case the sulfur it provides directly participates in the formation of a cross-linked network of single or double sulfur bonds. This characteristic gives the vulcanized rubber excellent resistance to heat and oxygen aging and extremely low compression set.

Tetramethylthiuram Disulfide also has a certain antioxidant function, and its decomposition products can capture free radicals generated during the aging process of rubber, playing a certain protective role on the rubber compound. In terms of processing safety and environmental protection characteristics, although its scorch time is relatively short and needs to be carefully controlled, modern processes can cope with it well; although there is carbon disulfide in its decomposition products that need attention, it is still safe to use under compliant operation and ventilation conditions.

Nature and Specifications:

| Item | Specification |

| Product Name | Tetramethylthiuram Disulfide |

| CAS No. | 137-26-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Refractive Index | 1.5500 (estimate) |

| Fp | 89°C |

| Storage Temp. | under inert gas (argon) |

| Solubility | 0.0184g/l |

| Form | solid |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Tetramethylthiuram Disulfide

Tetramethylthiuram Disulfide plays an irreplaceable and important role in rubber formulation design, and its application runs through a wide range of fields from general products to high-performance special rubbers. In the vulcanization system of general rubbers such as natural rubber (NR), styrene-butadiene rubber (SBR), butadiene rubber (BR), nitrile rubber (NBR) and isoprene rubber (IR), Tetramethylthiuram Disulfide is one of the core accelerators to increase the vulcanization speed and achieve short-time and efficient production.

Especially in the production of thin-walled products and high-yield molded products (such as seals, shock absorbing components, soles, etc.), its role in rapid vulcanization and shortening the vulcanization cycle is crucial. It is often designed to form a composite system with thiazole (such as M, DM) or sulfonamide (such as CZ, NS) accelerators. With its strong activation ability, it can significantly stimulate the potential of post-vulcanization, so that the delayed vulcanization characteristics of sulfonamide can be retained while bursting out extremely high vulcanization rates at high temperatures.

As an effective “sulfur carrier”, Tetramethylthiuram Disulfide plays a leading role in the construction of modern vulcanization systems (especially semi-effective vulcanization systems SEV and effective vulcanization systems EV). In the SEV system, Tetramethylthiuram Disulfide is often used with a moderate amount of sulfur and thiazole or sulfonamide accelerators to balance the vulcanization speed, physical and mechanical properties and aging resistance. This system is widely used in tire tread rubber and conveyor belt covering rubber that take into account production efficiency and product life requirements.

In the EV system, Tetramethylthiuram Disulfide becomes the main or only sulfur source (usually in higher amounts), supplemented by thiazoles or other accelerators, which completely provides the sulfur atoms required for cross-linking, forming a network rich in single and double sulfur bonds with high thermal stability, thereby giving the product excellent high temperature aging resistance, extremely low compression permanent deformation and good dynamic fatigue life, which is of great significance for demanding engine compartment seals, heat-resistant hoses, oil seals and other products.

The application of Tetramethylthiuram Disulfide is also critical in rubbers with high saturation and relatively slow vulcanization speed, such as butyl rubber (IIR) and ethylene propylene diene monomer rubber (EPDM). Its strong vulcanization accelerating effect is very effective in overcoming the problem of difficult vulcanization of butyl rubber and EPDM. In resin vulcanization and quinone oxime vulcanization systems, Tetramethylthiuram Disulfide is often added as an important activator or co-vulcanizer to significantly improve vulcanization efficiency and crosslinking density.

Especially in the fast vulcanization formula of EPDM, the synergistic combination of highly active accelerators such as Tetramethylthiuram Disulfide and other varieties of thiurams (such as TETD) or dithiocarbamates (such as ZDEC, ZDC), combined with a small amount of sulfur or sulfur carriers such as DTDM (morpholine disulfide), is a key technical path to achieve full vulcanization in short-cycle processes such as injection molding and compression molding.

In high-hardness, high-filled rubber products (such as hard rubber, rubber roller covering, wear-resistant lining), Tetramethylthiuram Disulfide can effectively overcome the inhibition of high filling content on vulcanization speed. Its strong promotion behavior and high vulcanization efficiency ensure that the required cross-linking degree can be achieved in a relatively short time in the presence of a large amount of fillers. At the same time, Tetramethylthiuram Disulfide has a certain activation effect on certain light-colored fillers.

In special application fields, Tetramethylthiuram Disulfide is also often used as a thermosensitive agent or auxiliary accelerator in the latex product industry, helping the latex to quickly gel when heated in the latex dipping process; in the activation modification of reclaimed rubber, it can promote the desulfurization chain breaking process to improve the plasticity and processability of reclaimed rubber; even in non-rubber fields (such as partial polymerization reactions, agricultural fungicides) can also be seen, but the core application is always focused on rubber vulcanization.

The Advantages Of Tetramethylthiuram Disulfide

The core technical competitiveness of Tetramethylthiuram Disulfide lies in its extremely high vulcanization speed. As a representative of super accelerators, it can initiate and complete the cross-linking process of rubber very quickly at a suitable temperature. This feature has unparalleled economic value in industrial scenarios of high efficiency and large-scale continuous production. Whether it is used in conjunction with sulfur to significantly increase the vulcanization speed, or to provide efficient cross-linking through the sulfur-free vulcanization system itself, Tetramethylthiuram Disulfide can shorten the vulcanization cycle to a critical level.

In the application of highly unsaturated rubbers such as natural rubber, Tetramethylthiuram Disulfide can effectively inhibit the “reversion” phenomenon during the vulcanization process. The conventional ordinary vulcanization system (CV) with a high sulfur dosage is prone to break and recombine the polysulfide cross-linking bonds (low bond energy) in the network at high temperatures, resulting in a decrease in cross-linking density and deterioration of physical properties.

The SEV or EV system in which Tetramethylthiuram Disulfide participates significantly improves the thermal stability of the cross-linking network due to the generation of a large number of stable single/double sulfur bonds. Therefore, even after long-term vulcanization or high-temperature exposure in subsequent use, the rubber can still maintain good physical and mechanical properties (such as tensile stress, tensile strength and resilience), which is crucial to ensure the long-term service reliability of the product under harsh conditions.

Another significant advantage of Tetramethylthiuram Disulfide is its excellent flexibility in combination. It can not only be used alone as a main accelerator or main vulcanizer, but also excels in producing strong synergistic effects with a variety of other types of accelerators (thiazoles, sulfonamides, guanidines, dithiocarbamates, etc.), especially its ability to catalyze the activation of sulfonamide accelerators is almost irreplaceable.

By adjusting its dosage, combination method and ratio with sulfur, formulation engineers can finely customize the required vulcanization curve shape (vulcanization speed, maximum torque), cross-linking network structure and final performance, thereby meeting the diverse needs from high-speed vulcanization with extreme efficiency to long-term service products with demanding aging resistance. This broad design space is difficult to achieve with a single-function accelerator.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Tetramethylthiuram Disulfide

Tetramethylthiuram Disulfide Manufacturer

Contact Us

As an experienced Tetramethylthiuram Disulfide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Tetramethylthiuram Disulfide CAS 137-26-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.