Styrenated Phenol CAS 61788-44-1

Factory wholesale Styrenated Phenol CAS 61788-44-1

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Styrenated Phenol

CAS: 61788-44-1

MOQ: 1KG

Directory Guidance on Styrenated Phenol

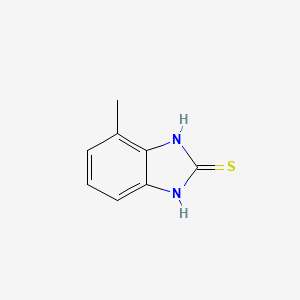

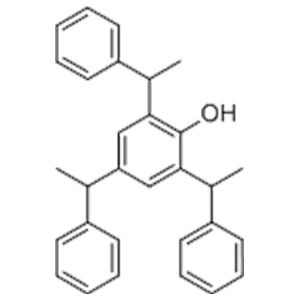

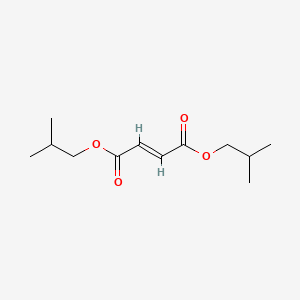

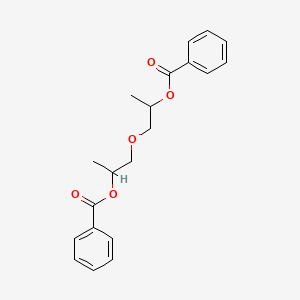

Chemical Structure

Basic Info:

| Boiling Point | >250℃ |

| Density | 1.08g/cm3 |

| Vapor Pressure | 0.1Pa at 20℃ |

| Refractive Index | 1.5785~1.6020 |

Styrenated Phenol Introduction:

From the perspective of the chemical synthesis pathway, Styrenated Phenol is usually prepared through the Friedel-Crafts alkylation reaction. Under the action of an acidic catalyst, styrene undergoes electrophilic substitution with the hydroxyl groups of phenol at the ortho or para positions, generating monosubstituted or polysubstituted products. The regulation of reaction conditions has a significant impact on the product structure. For instance, temperature, the type of catalyst and the ratio of raw materials will directly affect the position and quantity of substituents, thereby determining the performance of the final product.

From the perspective of physical properties, Styrenated phenols are mostly colorless or pale yellow viscous liquids at room temperature, and some highly substituted products may be in a solid state. Its solubility shows obvious polar characteristics. It is soluble in most organic solvents such as acetone, toluene and ethanol, but its solubility in water is relatively low.

Cationic polymerization usually uses protonic acid or Lewis acid as a catalyst. This type of reaction has extremely stringent requirements on the humidity and impurity content of the reaction environment, and needs to be carried out under anhydrous and oxygen-free conditions to prevent catalyst deactivation and the occurrence of side reactions. Anionic polymerization is relatively tolerant of impurities, but the purity of the reactants and the uniformity of the reaction temperature need to be strictly controlled during the reaction to avoid reaction runaway and product degradation caused by local overheating.

The development of Styrenated Phenol in the field of chemistry is quite tortuous and full of opportunities. In the early days, due to insufficient understanding of its synthesis reaction mechanism and the limitations of separation and purification technology, the output of Styrenated Phenol was low and the purity was not high, which limited its scope of application. However, with the continuous progress of the chemical industry and the increase in scientific research investment, people have gradually mastered more efficient polymerization catalysts and more precise reaction control technologies, which have significantly improved the production efficiency and product quality of Styrenated Phenol.

At the same time, driven by interdisciplinary disciplines such as materials science, new uses of Styrenated Phenol have been continuously discovered, from the initial use as a preservative, rust inhibitor, etc., to gradually expanding to applications in high-end fields such as resin modification, electronic materials, and coatings.

Styrenated Phenol has also been one of the hot spots in chemical research. Many scientific research teams are committed to the in-depth exploration of the relationship between its structure and performance. By changing the molar ratio of styrene to phenol, introducing different substituents, and adopting a variety of polymerization methods, a series of Styrenated Phenol derivatives with specific properties have been synthesized.

Nature and Specifications:

| Item | Specification |

| Product Name | Styrenated Phenol |

| CAS No. | 61788-44-1 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 182℃ |

| Solubility | 1000g/L in organic solvents at 20 ℃ |

| Pka | 0[at 20 ℃] |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Styrenated Phenol

In the industrial field, the application of Styrenated Phenol is mainly concentrated in the functional modification of polymer materials. As a highly efficient antioxidant, it is particularly widely used in rubber products. Rubber is susceptible to thermal oxidative aging during processing and use, resulting in a decrease in mechanical properties.

It can significantly delay the aging process of rubber through the dual action mechanism of quenching free radicals and decomposing peroxides. In addition, its good compatibility with the rubber matrix avoids surface frosting and ensures the appearance quality of the product.

In the plastic industry, Styrenated Phenol is mainly used as a heat stabilizer and light stabilizer. Polyolefin materials are prone to thermal degradation during high-temperature processing. Adding 0.3% -1.5% of this product can control the fluctuation of the material’s melt index within 5%. The styrene group in its molecule can form π – π conjugation with polymer segments, effectively inhibiting molecular chain breakage.

In plastic products used outdoors, this compound can also absorb ultraviolet energy and convert it into thermal energy for release, reducing the material’s photooxidation rate. Experimental data shows that the retention rate of fracture elongation of polyethylene film with added Styrenated Phenol is increased by about 40% in xenon lamp aging test.

The demand for Styrenated Phenol in the field of electronic chemicals has grown rapidly in recent years. As a modified component of film-forming resin, solder mask ink used in printed circuit boards can significantly improve the heat resistance and dielectric properties of the ink. The hydrophobic properties brought by styrene groups can also reduce the moisture absorption rate of ink and avoid insulation performance degradation in high humidity environments.

In semiconductor packaging materials, this compound can improve the fluidity and curing uniformity of the material by blending with silicone resin, and its thermal expansion coefficient can be controlled below 5ppm/℃, meeting the requirements of precision packaging.

The tightening of environmental regulations has promoted the application expansion of Styrenated Phenol in environmentally friendly materials. In the field of biodegradable plastics, it can balance the processing stability and degradation performance of materials as an antioxidant. Compared with mineral oil-based antioxidants, it has lower biological toxicity and meets the safety standards of food contact materials.

The Advantages Of Styrenated Phenol

Styrenated Phenol offers numerous advantages when it comes to performance. Thanks to its superior thermal stability and the ability of Styrenated Phenol to retain both chemical structure and performance at higher temperatures, it makes an excellent material choice for high-temperature processing environments such as packaging electronic devices requiring high-temperature curing processes; for instance the thermal stability provided by Styrenated Phenol ensures its performance continuity during this process.

Styrenated Phenol excels at performing its functional properties well. It boasts powerful antioxidant abilities to slow down aging and performance degradation caused by oxidation; in some polymer materials it can even be added as an antioxidative to inhibit this reaction by capturing free radicals or other mechanisms thereby prolonging durability of materials. Furthermore, its excellent electrical insulation properties make it a highly desirable material in electronic materials to meet stringent device insulation specifications and guarantee safe operation of electronic devices.

Styrenated Phenol offers substantial production cost advantages and economic returns. As its raw materials, styrene and phenol are both widely-available bulk chemicals within the petrochemical industry with relatively stable pricing structures that offer cost advantages when producing large-scale batches.

Chemical synthesis technology has continued to advance over time, increasing production efficiency while simultaneously decreasing costs. Meanwhile, Styrenated Phenol is widely applied across products, providing significant economic advantages and adding considerable value. These developments are of immense benefit in furthering industry advancement.

Styrenated Phenol also boasts environmental-friendliness advantages. When compared with some traditional organic chemical products, its production and use create significantly less pollution to the environment than their counterparts; less wastewater and waste gas emissions occur during production processes while many of those generated can be treated and discharged in accordance with existing environmental protection technologies.

During use, its low volatility and low toxicity make it pose less harm to the environment and human health, which is in line with the current society’s high regard for environmental protection and health.

The molecular structure of Styrenated Phenol is highly designable, which provides a broad space for its performance optimization and functional expansion. Researchers can precisely regulate the molecular structure of styrene and phenol by means of changing the degree of polymerization of styrene and phenol, introducing different substituent groups and adopting different polymerization methods.

As an example, adding long-chain alkyl groups into Styrenated Phenol molecules can improve its flexibility and lipophilicity; adding polar groups can increase compatibility and reactivity with polar materials; designing molecular structures this way allows them to adapt easily to ever-evolving market demand and allows the creation of novel high-performance materials.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Titanium Tetrachloride

Styrenated Phenol Manufacturer

Contact Us

As an experienced Styrenated Phenol manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Styrenated Phenol CAS 61788-44-1 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.

Contact us for the latest quotation and free samples of Styrenated Phenol

New Product

Hot Product