Sodium Hexametaphosphate CAS 57-57-8

Factory wholesale Sodium Hexametaphosphate CAS 57-57-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Sodium Hexametaphosphate

CAS: 57-57-8

MOQ: 1KG

Directory Guidance on Sodium Hexametaphosphate

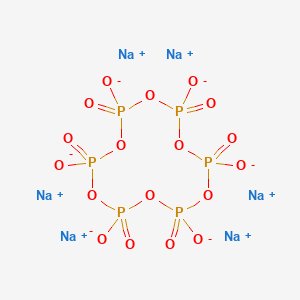

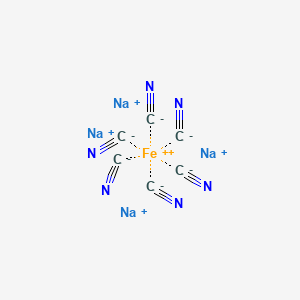

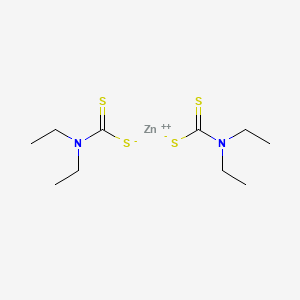

Chemical Structure

Basic Info:

| Melting Point | 616℃ |

| Boiling Point | 1500℃ |

| Density | 2.181 |

| Refractive Index | 1.482 |

Sodium Hexametaphosphate Introduction:

In the field of inorganic chemical engineering, Sodium Hexametaphosphate occupies a unique and important position. It is not a simple orthophosphate, but a complex mixture of cyclic or long-chain sodium polyphosphate salts formed by bridging multiple PO₃⁻ units with oxygen atoms. Among them, the hexmer form is relatively common, hence the name.

Its molecular structure endows it with a series of special chemical properties distinct from ordinary phosphates, making it an indispensable functional additive in numerous industrial categories. As a white powder or colorless transparent glass-like solid, Sodium Hexametaphosphate is relatively stable at normal temperature and pressure, but its behavior in aqueous solution is highly active.

The industrial production of Sodium Hexametaphosphate mainly uses sodium dihydrogen phosphate (NaH₂PO₄) or orthophosphoric acid (H₃PO₄) and soda ash (Na₂CO₃) or caustic soda (NaOH) as raw materials. The key step lies in conducting a dehydration polycondensation reaction of the mixed sodium phosphate salt at high temperatures (usually above 600°C), followed by rapid cooling (quenching) of the molten material to obtain a transparent glassy solid, and then crushing and grinding to obtain a powder-like finished product.

This high-temperature melting and polymerization process determines the degree of polymerization and main performance indicators of the product. Product quality is usually controlled and evaluated by the content of total phosphate (calculated as P₂O₅), the content of insoluble substances in phosphorus pentoxide, iron content, pH value, and most importantly, the binding ability with calcium ions (calculated as CaCO₃), etc.

From the perspectives of safety and environmental impact, Sodium Hexametaphosphate itself is a low-toxicity to slightly toxic substance and is relatively safe to use under regular industrial operations and prescribed dosage. However, like many phosphates, their large-scale discharge into water bodies may bring the risk of eutrophication, promote excessive algae growth, consume dissolved oxygen in water, and damage aquatic ecosystems.

Therefore, industrial wastewater containing Sodium Hexametaphosphate needs to be effectively treated and can be discharged only after meeting the standards. In food applications, its dosage is strictly restricted by regulations (such as the National Food Safety Standard GB 2760) to ensure that it functions within the safety threshold. When operating, it is still necessary to pay attention to avoiding dust inhalation and long-term skin contact, and take good environmental protection measures.

Nature and Specifications:

| Item | Specification |

| Product Name | Sodium Hexametaphosphate |

| CAS No. | 57-57-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Storage Temp. | 2-8°C |

| Form | Solid |

| Color | White |

| Odor | odorless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Sodium Hexametaphosphate

Sodium Hexametaphosphate plays multiple key roles in the food industry. It is widely used as a food quality improver. Its main functions include chelating metal ions, adjusting pH, improving protein water retention, stabilizing emulsification systems and preventing fat oxidation.

In addition, it is also commonly used in canned beans, fruits and vegetables. By softening water and integrating calcium and magnesium ions, it promotes water penetration, accelerates softening and improves texture.

In the field of water treatment, Sodium Hexametaphosphate is a long-standing and effective scale inhibitor and corrosion inhibitor. Its core function is to firmly bind scale-forming cations (mainly Ca²⁺ and Mg²⁺) in water through strong chelating ability, preventing them from combining with anions (such as CO₃²⁻, SO₄²⁻, SiO₃²⁻) to form insoluble scale deposited on the surface of pipes, boilers, heat exchangers, cooling towers and other equipment.

In the formulation of synthetic detergents and cleaning agents, Sodium Hexametaphosphate was once one of the key “synergists”. It has a certain ability to disperse and suspend dirt particles, preventing dirt from re-depositing. In addition, it can also provide a certain alkaline buffering capacity, maintain a suitable pH environment for the detergent, and optimize the cleaning efficiency of the surfactant.

Although it has been partially replaced by other additives (such as zeolite and layered sodium silicate) in some household detergents due to environmental considerations (eutrophication), Sodium Hexametaphosphate still maintains an important position in some industrial cleaning agents, hard surface cleaners, and automatic dishwasher detergents due to its excellent comprehensive performance.

In the ceramic, refractory and glaze industries, Sodium Hexametaphosphate is mainly used as an efficient debonding agent (water reducer) and suspension stabilizer. After adding Sodium Hexametaphosphate, its anionic properties make it adsorbed on the edge of positively charged clay particles, neutralizing the charge, which can significantly reduce the viscosity of the mud, improve the fluidity (i.e., debonding effect), and improve the grouting molding performance.

At the same time, it maintains the dispersed and stable state of particles, prevents sedimentation and stratification, ensures uniform suspension of glaze slurry, facilitates glazing operation and obtains uniform glaze layer. In refractory castables, it also plays a similar role in improving fluidity and construction performance.

In the textile printing and dyeing industry, Sodium Hexametaphosphate is mainly used for water softening and is an important pre-treatment auxiliary in the printing and dyeing process. Adding this product can effectively chelate harmful metal ions, soften process water, ensure normal color development and fixation of dyes, improve color fastness and levelness, improve bleaching efficiency and protect fibers, and prevent soap scum from contamination. It is also commonly used to prepare pre-treatment auxiliary agents such as scouring agents and penetrants to improve the wetting and penetration properties of the treatment solution.

In the field of metal surface treatment and processing, the application of Sodium Hexametaphosphate is also indispensable. In metal cleaning (such as electroplating pretreatment, coating pretreatment), it is used as a cleaning agent component to prevent the formation of spots or water marks on the surface of the cleaned parts by chelating the hardness and metal ions in the water, and enhance the emulsification and dispersion effect of the cleaning agent on grease and dirt.

In the electroplating solution, it can be used as an auxiliary complexing agent to help stabilize the composition of the plating solution (such as controlling the state of metal ions such as zinc and copper), refine the crystallization of the coating, and improve the gloss and uniformity of the coating. In addition, it is also a commonly used high-efficiency dispersant in the production and dispersion process of pigments and fillers (such as calcium carbonate, kaolin, and titanium dioxide).

The Advantages Of Sodium Hexametaphosphate

The core and incomparable advantage of Sodium Hexametaphosphate lies in its excellent chelating ability, especially its binding ability to calcium ions (Ca²⁺), which ranks among the best among common industrial phosphates. This broad-spectrum, strong, and wide pH adaptability chelating ability is the fundamental reason why it is difficult to be completely replaced in applications such as water treatment scale prevention, food metal catalysis prevention, and printing and dyeing soft water.

Sodium Hexametaphosphate shows significant economic advantages in application, mainly reflected in its efficient “threshold effect”. This low dosage, high efficiency, and relatively low cost make it a very cost-effective choice in industrial fields that require large-scale and continuous use of chelating agents (such as industrial water treatment, detergents, and some food processing).

In terms of safety, Sodium Hexametaphosphate has a relatively reliable safety record under standardized use. Its acute oral toxicity (LD50) is low toxic or practically non-toxic. In the food industry, it is a legal food additive (such as a moisture retainer and quality improver), and its scope of use and maximum allowable dosage are subject to food safety regulations in various countries. In industrial applications, its operational risks mainly lie in dust (need to prevent inhalation) and avoid large-scale discharge into water bodies (environmental protection requirements). Compared with some organic chelating agents (such as certain amines, chlorinated solvents) or strong acids and alkalis, it is less corrosive and the potential hazards to equipment and operators are relatively controllable.

Sodium Hexametaphosphate shows significant economic advantages in application, mainly reflected in its efficient “threshold effect”. This low dosage, high efficiency, and relatively low cost make it a very cost-effective choice in industrial fields that require large-scale and continuous use of chelating agents (such as industrial water treatment, detergents, and some food processing).

In terms of safety, Sodium Hexametaphosphate has a relatively reliable safety record under standardized use. Its acute oral toxicity (LD50) is low toxic or practically non-toxic. In the food industry, it is a legal food additive (such as a moisture retainer and quality improver), and its scope of use and maximum allowable dosage are subject to food safety regulations in various countries. In industrial applications, its operational risks mainly lie in dust (need to prevent inhalation) and avoid large-scale discharge into water bodies (environmental protection requirements). Compared with some organic chelating agents (such as certain amines, chlorinated solvents) or strong acids and alkalis, it is less corrosive and the potential hazards to equipment and operators are relatively controllable.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Sodium Hexametaphosphate

Sodium Hexametaphosphate Manufacturer

Contact Us

As an experienced Sodium Hexametaphosphate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Sodium Hexametaphosphate CAS 57-57-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.