Sodium Bisulfite CAS 7631-90-5

Factory wholesale Sodium Bisulfite CAS 7631-90-5

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Sodium Bisulfite

CAS: 7631-90-5

MOQ: 1KG

Directory Guidance on Sodium Bisulfite

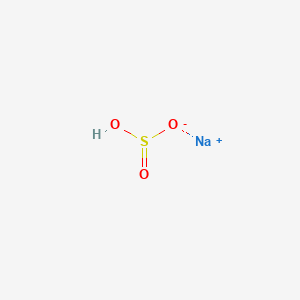

Chemical Structure

Basic Info:

| Melting Point | 150 °C |

| Density | 1.48 |

| Vapor Pressure | 40 hPa ( 20 °C) |

| Storage Temp. | Store at RT. |

| Solubility | 300 g/L |

Sodium Bisulfite Introduction:

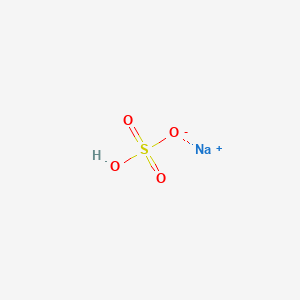

The physical properties of Sodium Bisulfite are quite characteristic: it usually appears as prismatic or plate-like crystals, has a faint sulfur smell, is very soluble in water (the aqueous solution is acidic), and can be slowly oxidized in the air. Compared with its “close relative” sodium sulfite (Na₂SO₃), its molecular structure contains a dissociable hydrogen atom, which is relatively more acidic, more soluble in water, and has a tendency to oxidize and deteriorate more easily in the air, which is a factor that requires special attention in its use.

The molecular structure of Sodium Bisulfite determines its core value. As an acid salt, it dissociates in aqueous solution to produce bisulfite ions (HSO₃⁻), which have strong reduction potential and can provide hydrogen atoms or electrons to participate in redox reactions, making Sodium Bisulfite an important reducing agent in the chemical field.

The industrial production of Sodium Bisulfite mainly follows two mature process paths. The most common route is to absorb sulfur dioxide (SO₂) gas with soda ash (sodium carbonate, Na₂CO₃) or caustic soda (sodium hydroxide, NaOH). Controlling the molar ratio of the reactants is the core technical link, the purpose of which is to maximize the crystallization of the final product as a single salt state of Sodium Bisulfite.

The other path is to achieve conversion by absorbing sulfur dioxide gas with sodium sulfite (Na₂SO₃) solution. This route usually uses surplus sulfur dioxide raw materials to produce Sodium Bisulfite while preparing sodium sulfite, which reflects the advantages of industrial co-production and resource intensiveness. Therefore, precise control of sulfur dioxide gas concentration and judgment of reaction endpoint are crucial to obtain high-purity, standard-compliant products.

During the storage, transportation and use of the product, due to its characteristics of being hygroscopic and easily oxidized to sulfate, Sodium Bisulfite must be packaged in well-sealed containers and stored in a cool, dry and well-ventilated environment, away from oxidants, strong acids and moist air, in order to slow down its deterioration process to the greatest extent.

During the operation, appropriate personal protective equipment must be worn to prevent dust inhalation or solution contact with skin and mucous membranes. At the same time, the working environment should ensure good ventilation conditions, because its decomposition may produce sulfur dioxide gas with a pungent odor. Standardized storage and operation not only ensure its stable performance, but also greatly reduce safety risks and environmental loads.

Nature and Specifications:

| Item | Specification |

| Product Name | Sodium Bisulfite |

| CAS No. | 7631-90-5 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Form | Powder/Solid |

| Specific Gravity | 1.48 |

| Color | White |

| PH | 4.5 (20°C in H2O) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Sodium Bisulfite

In the food and beverage industry, Sodium Bisulfite (usually in solution form) is a widely recognized food additive that mainly undertakes the task of strong preservation. It inhibits the growth and metabolism of molds, yeasts and some bacteria by significantly reducing the redox potential of the living environment of food microorganisms;

At the same time, as a highly efficient antioxidant, it can quickly capture the reaction product quinone catalyzed by endogenous polyphenol oxidase in fruit and vegetable tissues, thereby effectively preventing or delaying the occurrence and development of enzymatic browning reactions, which is essential for maintaining the color and fresh flavor of canned fruits, dried vegetables and fruits, fruit wine, fruit juice drinks, etc.

In the field of water treatment applications, the core value of Sodium Bisulfite lies in its strong dechlorination ability. Its aqueous solution can quickly and quantitatively react with free chlorine (Cl₂) and hypochlorite ions (ClO⁻) dissolved in water to generate inert chloride ions (Cl⁻) and sulfate ions (SO₄²⁻), completely eliminating the residual effectiveness of oxidative disinfectants.

This highly efficient dechlorination property enables it to play a key safety role in the post-treatment unit of the tap water treatment plant, the pre-treatment of the influent of the reverse osmosis membrane device of the industrial circulating cooling water system, and the ultrapure water preparation process of the precision manufacturing industry.

The chemical pharmaceutical industry’s reliance on Sodium Bisulfite mainly focuses on its reducing ability. In many organic synthesis processes, it is selectively used as a mild reducing agent, especially in the synthesis stage of key intermediates of complex drug molecules, to reduce certain nitro functional groups to amino functional groups, or to break azo chromophores to obtain specific structural units.

In certain specific polymer polymerization processes, it is used as a reducing agent component in the redox initiation system in combination with peroxide to achieve a more controllable chain initiation process at a lower temperature. In addition, in specific sulfonation reactions, Sodium Bisulfite may also participate in the sulfonation conversion process of specific substituent groups.

The textile industry is one of the important areas of Sodium Bisulfite consumption. In continuous dyeing or printing production lines, especially in the pre-treatment of natural fiber fabrics such as cotton and linen, the treatment bath containing it is mainly used to remove residual oxidants (such as hydrogen peroxide) on the fabric after bleaching to prevent these residues from causing fiber damage or color changes in subsequent dyeing or finishing. This step is specifically called “deoxygenation” or “deoxidation” process, which is the core process to ensure the brightness and uniformity of dyeing.

On the other hand, in the process of making rayon (viscose fiber) from cellulose fibers, Sodium Bisulfite is used to dissolve lignin and maintain the stability of cellulose xanthate spinning solution, playing a protective role in specific viscose fiber production routes. In addition, it is also used as an important component of reducing aids in specific types of reducing dye dyeing processes.

The papermaking industry is a traditional application of Sodium Bisulfite and its salts (collectively referred to as sulfite process). In specific pulp preparation processes (such as sulfite pulping), the main components of its core cooking liquor include bisulfite ions and sulfite ions. Under appropriate pH control conditions, the liquid can dissolve the lignin and polysaccharide components that connect the fibers in the wood relatively gently and effectively, and separate the fiber bundles for subsequent papermaking.

Compared with the strong sulfide smell produced by the sulfate pulping process, the environmental characteristics of the sulfite process are more friendly. In the middle or terminal wastewater treatment of the papermaking process, it is also used to effectively reduce toxic heavy metals such as hexavalent chromium ions, reduce their ecotoxicity and promote removal efficiency.

The Advantages Of Sodium Bisulfite

Its primary core competitiveness comes from its multifunctional integrated properties. Sodium Bisulfite provides the triple functions of redox regulation (strong reducing agent), acid-base buffering (weak acid regulation), and specific ion removal (especially free chlorine) almost at the same time. This high degree of integration greatly enhances its value in complex fluid treatment systems.

Take industrial boiler water pretreatment or reverse osmosis membrane equipment water inlet protection as an example: a single addition can not only effectively remove residual chlorine with strong oxidative destructive power (reduction effect), but also gently adjust the pH value of the water system (buffering effect) to avoid the sensitive corrosion range of the equipment. This ability to integrate process goals that originally require multiple independent steps to achieve into an efficient unit operation significantly reduces the processing links, reduces equipment investment and operation management complexity, and improves the reliability and economy of the overall treatment process.

Excellent reduction efficiency and reaction specificity constitute the core of its technical barriers. Under mild reaction conditions (normal temperature water environment), Sodium Bisulfite can show a high reduction reaction rate and conversion efficiency. Its reaction with common oxidants (especially chlorine, peroxides, and some high-valent heavy metal ions) is usually rapid and thorough, without producing complex by-products.

This high selectivity and high rate characteristics are particularly important in time-sensitive or automated control scenarios. For example, in the production stage of precise printed electronics or pharmaceutical intermediates, the ability to immediately terminate the influence of residual oxidants is decisive for ensuring the reliable quality of the end product. And its good chemical specificity is also conducive to the precise anticipation and control of treatment results in industrial design.

The significant cost-effectiveness and raw material accessibility have undoubtedly laid a solid foundation for its industrial application. As a mature large-scale inorganic chemical product, Sodium Bisulfite relies on mature sulfur dioxide tail gas recovery technology and bulk acid and alkali production technology to be mass-produced, and the acquisition cost per unit mass is extremely competitive in the field of reducing agents.

Compared with other synthetic reducing agents such as sodium borohydride or dithionite, it has a huge advantage in terms of procurement cost; and compared with metal reducing powders (such as zinc powder and iron powder), it shows comprehensive cost-effectiveness at the operational level in terms of the convenience of dosing operation, dissolution uniformity and difficulty in handling the residue after the reaction. This affordability based on large-scale production and mature processes is one of the key reasons why it can penetrate into the routine processes of various industries rather than remain in the experimental pilot stage.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Sodium Bisulfite

Sodium Bisulfite Manufacturer

Contact Us

As an experienced Sodium Bisulfite manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Sodium Bisulfite CAS 7631-90-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.