Potassium Silicate CAS 1312-76-1

Free Sample Potassium Silicate CAS 1312-76-1

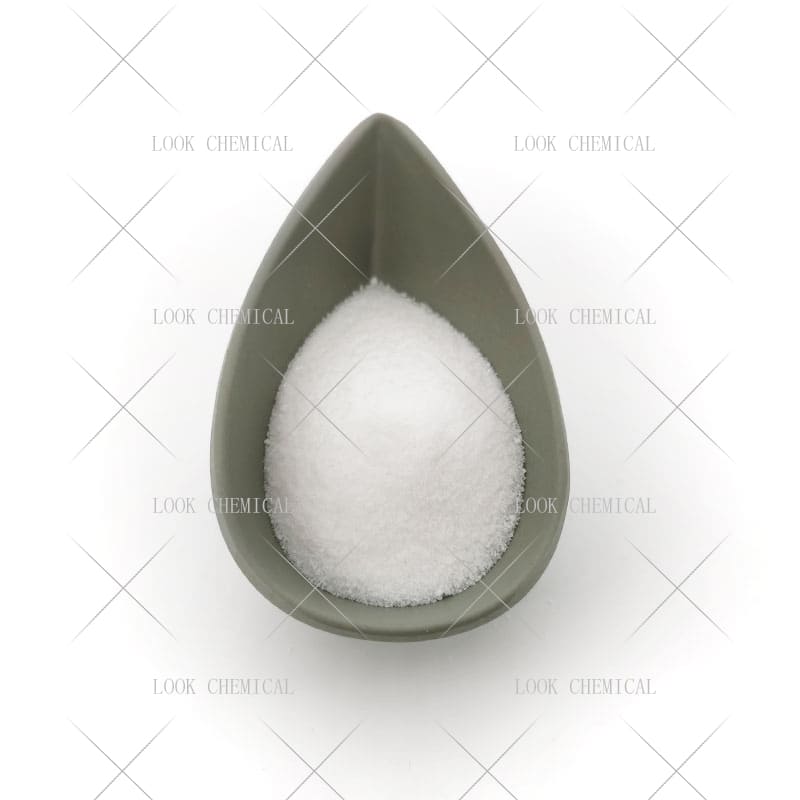

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Potassium Silicate

CAS:1312-76-1

MOQ: 1KG

Directory Guidance on Potassium Silicate

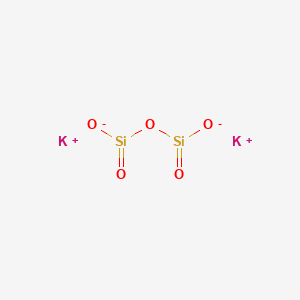

Chemical Structure

Basic Info:

| Melting point | >300°C |

| density | 1.203-1.209 g/cm3 |

| form | Powder |

| color | White |

Product Introduction:

Potassium Silicate (chemical formula K₂SiO₃) is an inorganic compound composed of potassium, silicon, and oxygen elements, usually existing in liquid or solid form. Its liquid form is a transparent or light green viscous solution, and its solid form is a glassy substance with significant chemical stability. The core characteristics of this compound come from its silicon-oxygen bond structure, which enables it to maintain a high degree of reaction inertness in both acidic and alkaline environments. The preparation process is mainly divided into high-temperature melting method and solution reaction method. The melting method generates a melt by reacting silica sand with potassium hydroxide at 1200~1400℃, and then dissolving and concentrating it through high-pressure steam to obtain the finished product; the solution method adjusts the ratio of silicon source to potassium salt to control the modulus of the product (SiO₂/K₂O ratio) to meet different application requirements. Low modulus Potassium Silicate is highly water-soluble and suitable for liquid waterproofing agents or coating bases, while high modulus products are easy to form a gel state and are mostly used in the field of refractory materials or adhesives.

From the perspective of physical properties, Potassium Silicate solution is slightly alkaline (pH 9-12), and the viscosity increases significantly with the concentration. This characteristic makes it have both fluidity and film uniformity in coating construction. It is worth noting that liquid Potassium Silicate is sensitive to carbon dioxide in the air. Long-term exposure will generate potassium carbonate, resulting in performance degradation, so sealed storage is a key requirement in industrial applications.

The historical application of Potassium Silicate can be traced back to the end of the 19th century. After the German chemist Kem obtained a patent in 1878, its properties as a mineral coating base were gradually discovered. After more than a hundred years of technological iteration, the modern product has expanded from the traditional construction field to multiple industries such as electronics, agriculture, and chemicals.

Nature and Specifications:

| Item | Specification |

| Product Name | Potassium Silicate |

| CAS No. | 1312-76-1 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Water Solubility | Soluble in water. |

| Merck | 14,7668 |

| CAS DataBase Reference | 1312-76-1(CAS DataBase Reference) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

However, when it comes to actual implementation, things change significantly. Here at CWC we take great pleasure in offering an in-house professional installation service which caters for a range of different clients’ requirements – be they residential or commercial projects. Potassium Silicate provides effective building protection, penetrating porous materials such as masonry and concrete to form water-insoluble calcium silicate gel which closes capillary pores while maintaining air permeability, effectively reducing freeze-thaw damage caused by water erosion. As opposed to organic coatings that often yellow and shed over time, surfaces treated with Potassium Silicate remain colorless and transparent over a prolonged period, making it particularly suitable for scenes requiring strict aesthetic standards, such as historical building restoration.

Used as part of wafer cleaning agents, Potassium Silicate helps remove metal impurities and particulate contaminants on semiconductor surfaces to increase yield rates of integrated circuits. Display panel manufacturing utilizes Potassium Silicate as part of their phosphor bonding layer coating system to maintain uniformity and long-term stability; additionally it is often included as an auxiliary component in packaging materials to increase moisture and heat resistance of components.

Potassium Silicate’s application in the chemical industry can be seen through its catalytic and adsorption properties. Organic synthesis uses it as a solid catalyst carrier, increasing reaction rate and product selectivity; wastewater treatment utilizes its strong adsorption capacity to remove heavy metal ions and organic pollutants; additionally it should be noted that Potassium Silicate must maintain solubility above pH 11.3, in order to avoid premature reaction with calcium or magnesium ions leading to precipitation – all factors which set forth stringent requirements for process control.

Innovative applications in agriculture show another facet of Potassium Silicate’s value. As a water-soluble silicon fertilizer, Potassium Silicate is taken up by plants in their cells in an ionic form and enhances mechanical strength of cell walls while improving crop resistance to lodging, pests and diseases. Studies have demonstrated how rational application of Potassium Silicate can reduce incidences by over 40% for barley crops while simultaneously increasing transport efficiency through strict concentration control while working synergistically with other nutrients to avoid antagonistic interactions between components.

Potassium Silicate continues to expand its role in environmental protection. When used as a flocculant, Potassium Silicate can effectively remove suspended solids and colloidal particles in wastewater treatment, providing effluent quality that meets national standards; waste gas purification involves reacting with acidic gases to form stable salts which reduce pollutant emissions; furthermore it also shows great promise as resource utilization tool by turning industrial waste residues into Potassium Silicate-based building materials to realize a circular economy model.

Potassium Silicate’s environmental friendliness is its core advantage. Its raw materials – silicon, oxygen and potassium – are some of the most abundant elements on Earth, making its production process far less reliant on petrochemical resources than traditional organic materials while VOC emissions are one-fourth of traditional organic materials. Potassium Silicate-based mineral coatings absorb carbon dioxide during curing processes thus indirectly reducing greenhouse gas concentrations thereby making this carbon capture property highly competitive under stringent regulations such as EU REACH regulations.

Chemical stability makes Potassium Silicate highly durable. Experimental data has demonstrated this by showing that when exposed to accelerated weathering experiments, stones treated with Potassium Silicate experience a 62% lower compressive strength decay rate compared to untreated samples; and their protective effect can last more than 10 years. When it comes to metal corrosion protection, the silica gel layer created can block oxygen and moisture penetration to steel structures exposed to salt spray environments; significantly decreasing corrosion rates by 75%! Not only does this provide maintenance savings, but its long-term effect also reflects economic advantages through life cycle assessments.

Potassium Silicate’s functional adjustability expands its application scope. By altering modulus or adding additives such as nano zinc oxide, derivative materials with self-cleaning, antibacterial or conductive properties can be created. While maintaining air permeability, surface contact angles of nano Potassium Silicate composite coating can reach 150deg, creating a superhydrophobic effect; its technical ductility also enables it to quickly respond to emerging industries, like solar cell encapsulation materials in new energy sectors.

Potassium Silicate’s nonflammable nature and alkaline environment (pH>10) make it significantly safer than organic solvent-based products in terms of safety performance, while meeting mold prevention requirements without toxic mildew inhibitors or fire safety standards for building materials. Furthermore, Potassium Silicate doesn’t emit toxic gases at high temperatures and meets fire safety regulations for building materials.

Economic benefits have seen large-scale production technology for Potassium Silicate mature, with unit production costs declining by 30% since 2010. When used as coating material in construction applications, comprehensive construction costs are 15%-20% lower than with organic coatings while maintenance cycle length has increased more than threefold compared with organic coatings; due to this cost advantage combined with performance enhancement it has found increased usage across infrastructure, electronics and agriculture industries.

Contact Us

Product Package picture:

Related References:

chemicalbook-Potassium Silicate

Potassium Silicate Manufacturer

Contact Us

As an experienced Potassium Silicate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Potassium Silicate CAS 1312-76-1 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.