Polyvinylpyrrolidone CAS 9003-39-8

Factory wholesale Polyvinylpyrrolidone CAS 9003-39-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polyvinylpyrrolidone

CAS: 9003-39-8

MOQ: 1KG

Directory Guidance on Polyvinylpyrrolidone

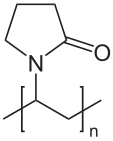

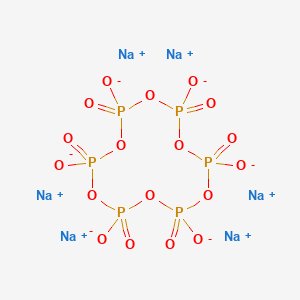

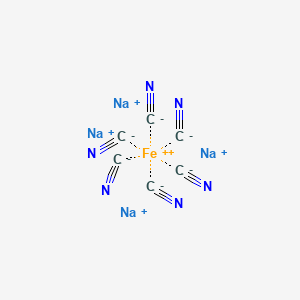

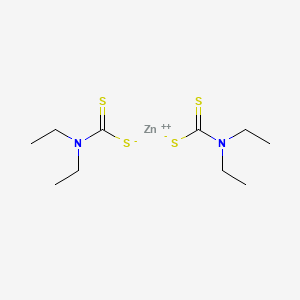

Chemical Structure

Basic Info:

| Melting point | >300 °C |

| Boiling point | 90-93 °C |

| bulk density | 330kg/m3 |

| density | 1,69 g/cm3 |

| Tg | 175 |

Polyvinylpyrrolidone Introduction:

Polyvinylpyrrolidone (abbreviated as PVP) is a water-soluble high-molecular compound generated by the free radical polymerization of N-vinylpyrrolidone monomer. Its molecular main chain is of carbon-carbon structure, and the side chains contain highly polar pyrrolidone rings. This unique chemical structure endows it with excellent solubility, adsorption and biocompatibility. Since its first synthesis by German scientists in the 1930s, PVP has gradually become an indispensable functional material in the fields of medicine, cosmetics, industry, etc. due to its multi-functional properties.

The physical form of Polyvinylpyrrolidone is usually white or light yellow powder. It is readily soluble in water and various polar solvents (such as ethanol and chloroform), but insoluble in non-polar solvents. Its aqueous solution has a relatively high viscosity, and the viscosity increases significantly with the increase of molecular weight. According to the difference in molecular weight, PVP can be divided into various models, such as K15, K30, K90, etc., where the “K value” represents its average molecular weight range.

In terms of chemical properties, Polyvinylpyrrolidone exhibits a high degree of chemical stability. In addition, PVP has strong complexing ability and can form reversible complexes with a variety of metal ions, dyes and small molecular organic matter. This property makes it of great value in the fields of drug carriers and catalyst loading. From the perspective of biosafety, Polyvinylpyrrolidone is widely regarded as a low-toxic, non-irritating material. It has passed a number of international safety certifications and is suitable for human contact products.

As a synthetic polymer, the preparation process of Polyvinylpyrrolidone has been optimized for decades and has formed a mature industrial production system. Its polymerization reaction is usually carried out in solution or bulk. By controlling the reaction temperature, initiator concentration and monomer feed ratio, the molecular weight distribution of the product can be precisely regulated. In recent years, with the promotion of the concept of green chemistry, some enterprises have begun to explore environmentally friendly polymerization processes using water as the solvent, further reducing the use of organic solvents in the production process.

Nature and Specifications:

| Item | Specification |

| Product Name | Polyvinylpyrrolidone |

| CAS No. | 9003-39-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| refractive index | (25) 1.5300 |

| refractive index | 1.5300 |

| storage temp. | 2-8°C |

| solubility | H2O: soluble100mg/mL |

| form | powder |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Polyvinylpyrrolidone

In the pharmaceutical field, the application of Polyvinylpyrrolidone runs through almost the entire process of drug development and production. As a binder for solid preparations, PVP can effectively improve the fluidity of powders and enhance the mechanical strength of tablets; in liquid preparations, it is often used as a thickener or stabilizer to prevent active ingredients from settling or agglomerating.

More importantly, Polyvinylpyrrolidone has a unique role in drug delivery systems – its molecules can bind to drugs through hydrogen bonds or van der Waals forces to form stable solid dispersions, thereby significantly improving the dissolution rate and bioavailability of poorly soluble drugs. In addition, PVP also occupies an important position in the field of medical devices, such as being used as a hydrophilic coating for hemodialysis membranes or preparing medical catheters with anticoagulant properties.

Polyvinylpyrrolidone’s wide array of film-forming and moisturizing properties has made it an integral component of many cosmetics products, from styling hair gels and facial masks to skin creams and makeup removal products.In hair care products, the transparent film formed by PVP can fix the hairstyle while avoiding stiffness.In recent years, with the growing demand for “residue-free” cosmetics from consumers, the easy-to-clean feature of Polyvinylpyrrolidone has further driven the innovation of its application in makeup remover products.

The application in the industrial field fully demonstrates the versatility of Polyvinylpyrrolidone. In the coating and ink industry, PVP as a dispersant can effectively prevent the agglomeration of pigment particles and ensure uniform color of the coating; in textile printing and dyeing, its complexation with dyes can improve color fastness and reduce dye residues in wastewater.PVP is widely utilized in electronics manufacturing to prepare photoresists or act as temporary protective films for semiconductor wafers, meeting precision manufacturing’s stringent purity and impurity requirements. Furthermore, its high purity meets environmental protection needs by acting as a flocculant to treat industrial wastewater and purify water by binding heavy metal ions or organic pollutants from entering.

Food grade Polyvinylpyrrolidone products can be used as clarifiers in juice and beer production to increase transparency by absorbing polyphenols, while in agriculture PVP acts as film-forming material for seed coating agents to improve stress resistance and slow release pesticides; PVP cell cryoprotectants help decrease ice crystal formation while increasing cryopreservation recovery rates of biological samples; these multidisciplinary applications not only demonstrate Polyvinylpyrrolidone’s versatility but also encourage its continued production processes.

The Advantages Of Polyvinylpyrrolidone

The core advantage of Polyvinylpyrrolidone lies in its outstanding chemical stability and environmental adaptability. Whether under high-temperature sterilization conditions (such as a 121℃ high-pressure steam environment) or strong oxidizing media (such as hydrogen peroxide solution), PVP can maintain the integrity of its molecular structure and will not release harmful by-products. This characteristic makes it the preferred material in scenarios that require long-term stability or harsh processing conditions. For instance, in the production of injections, Polyvinylpyrrolidone needs to withstand a high-temperature filling process without affecting its performance, ensuring the safety of the final product.

Biocompatibility is the key competitiveness of Polyvinylpyrrolidone that distinguishes it from other synthetic polymers. A large number of toxicological experiments have shown that PVP has no accumulation in the body and can be completely excreted through the kidneys. Its models with a molecular weight greater than 10,000 cannot penetrate biological membranes, further reducing the risk of systemic toxicity. This safety makes it widely used in products that directly contact biological tissues, such as implantable medical devices and eye drops. At the same time, PVP is non-irritating to the skin and mucous membranes, meeting the strict regulatory requirements for cosmetic raw materials.

The compatibility of Polyvinylpyrrolidone with a variety of substances has opened up a wider application space for it. In complex formulation systems, PVP can not only synergize with anionic surfactants (such as enhancing the foam stability of shampoo), but also form an interpenetrating network structure with non-ionic polymers (such as polyvinyl alcohol) to improve the mechanical properties of the material. In pharmaceutical preparations, PVP can be well compatible with excipients of different pH values, avoiding precipitation or phase separation phenomena. This “versatile” feature significantly reduces the difficulty and cost of formula development.

From the perspective of functional design, the molecular modiitability of Polyvinylpyrrolidone makes it possible for customized applications.By introducing functional groups such as carboxyl and amino groups through chemical modification, PVP can be given special functions such as pH responsiveness and targeted adsorption. For example, the solubility of carboxylated PVP changes suddenly under a specific pH environment, which can be used to design a colon-targeted drug delivery system; quaternized PVP exhibits antibacterial activity, expanding its application potential in wound dressings. This flexible functional expansion capability enables it to continue to meet the needs of emerging fields.

Environmental protection and economic advantages are also important reasons why Polyvinylpyrrolidone is so popular. Its water-soluble properties greatly reduce the use of organic solvents and reduce VOCs emissions during the production process. Compared with natural polymers (such as gelatin), PVP has higher batch-to-batch quality stability and is not affected by raw material origin or seasonal fluctuations. From a full life cycle cost analysis, although PVP has a higher unit price, its comprehensive benefits in improving product performance and reducing the amount of excipients are often more competitive.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polyvinylpyrrolidone

Polyvinylpyrrolidone Manufacturer

Contact Us

As an experienced Polyvinylpyrrolidone manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polyvinylpyrrolidone CAS 9003-39-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.