Polymaleic Acid CAS 26099-09-2

High Quality Polymaleic Acid CAS 26099-09-2 With Good Service

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polymaleic Acid

CAS: 26099-09-2

MOQ: 1KG

Directory Guidance on Polymaleic Acid

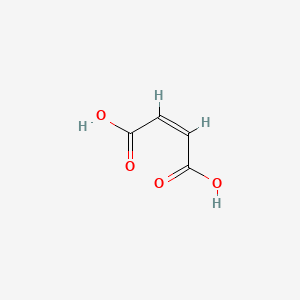

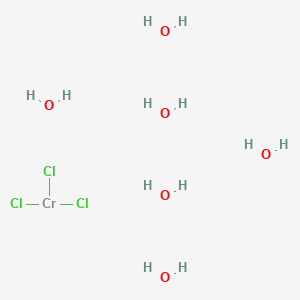

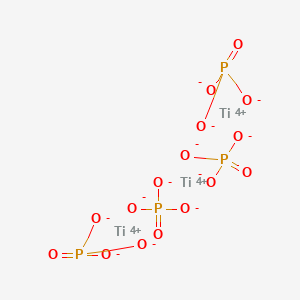

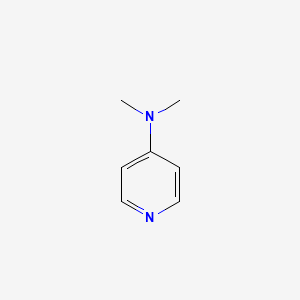

Chemical Structure

Basic Info:

| density | 1.18 (48% aq.) |

| Fp | 95 °C |

| storage temp. | 2-8°C |

| solubility | Methanol (Sparingly), Water (Soluble) |

| form | Pale Yellow to Yellow Solution |

Product Introduction:

Polymaleic Acid is an important water-soluble polymer, usually light yellow to brownish red transparent liquid, with a certain viscosity, easily soluble in water, the pH value of its 1% aqueous solution is between 2.0 and 3.0, the relative density is 1.2 (20°C), the average molecular weight is about 600, the general relative molecular weight is 400-800, non-toxic, chemical stability and thermal stability are high, and the decomposition temperature is above 330°C. Polymaleic Acid is obtained by partial hydrolysis of maleic anhydride and belongs to the polycarboxylic acid scale inhibitor dispersant. Its production process mainly includes two steps: polymerization and hydrolysis of maleic anhydride. In the polymerization stage, maleic anhydride monomer undergoes chain polymerization reaction under the action of initiator to generate high molecular weight polymaleic anhydride. Common initiators include peroxides, azo compounds, etc.; in the hydrolysis stage, polymaleic anhydride undergoes hydrolysis reaction under acid or base catalysis to break part of the anhydride bonds and introduce carboxylic acid groups to obtain the product.

Polymaleic Acid has good scale inhibition performance. It can form chelates with calcium, magnesium and other ions in water to prevent these ions from depositing and forming scale. It can also promote lattice distortion, so that the formed tiny crystals are dispersed in the aqueous solution instead of aggregating into large crystal precipitation. It has a good scale inhibition effect on carbonate, phosphate and other scales, with a scale inhibition rate of up to 98% and a scale inhibition time of up to 100 hours. In addition, the oxygen atoms in the polar groups in its molecules can become adsorption centers, form chelates with metal ions in water, adsorb on the metal surface, form a protective film, and thus play a corrosion inhibition role. When compounded with zinc salts, it can more effectively prevent the corrosion of metals such as carbon steel. Polymaleic Acid also has excellent dispersibility, which can disperse fine particles suspended in water, prevent them from aggregating to form sediments, and help keep the system clean.

In terms of safety, Polymaleic Acid is non-toxic and environmentally friendly. It can be degraded by microorganisms, and its degradation products have no negative impact on the ecological environment. However, as an acidic substance, it should be avoided from contact with sensitive parts such as skin and eyes. If contact occurs, it should be immediately rinsed with plenty of water and medical treatment should be sought as appropriate.

Nature and Specifications:

| Item | Specification |

| Product Name | Polymaleic Acid |

| CAS No. | 26099-09-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| solubility | Methanol (Sparingly), Water (Soluble) |

| form | Pale Yellow to Yellow Solution |

| Odor | Slight |

| InChI | InChI=1S/C4H4O4/c5-3(6)1-2-4(7)8/h1-2H,(H,5,6)(H,7,8)/b2-1- |

| InChIKey | VZCYOOQTPOCHFL-UPHRSURJSA-N |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Polymaleic Acid’s scale and corrosion inhibiting properties have long been recognized for use in industrial water treatment applications. Circulating cooling water systems have the capacity to increase scale inhibition rates to over 98% by inhibiting calcium carbonate and calcium sulfate formation while simultaneously extending equipment cleaning cycles to 100 hours. Polymaleic Acid has proven its worth as an efficient tool in protecting medium and low pressure boiler systems from mineral salt deposition at higher temperatures and pressures, thus decreasing thermal efficiency losses and saving on overall costs. Compounding with sodium ethylenediaminetetramethylenephosphonate (EDTMPS) at a ratio of 1:3, the scale inhibition effect can be further enhanced, becoming a mainstream solution for in-furnace water treatment. Furthermore, seawater desalination devices often employ flash evaporation devices using this substance due to its high temperature resistance which greatly reduces scaling risks while prolonging equipment lifespans.

Oilfield chemistry is another key application area for Polymaleic Acid. When extracting oil and gas, Polymaleic Acid can serve multiple roles during extraction: as an anti-scaling agent to prevent mineral salt deposits from depositing on pipes and equipment to avoid blockage or corrosion; as an electrochemical corrosion inhibitor (zinc salts can synergize with this compound to decrease corrosion by up to 69.3%); it also improves fluidity of oilfield water for efficient extraction processes, particularly those found in high temperature/high salt reservoir environments.

Textile printing and dyeing industries rely on Polymaleic Acid’s dispersant properties to optimize production processes. When dyeing, Polymaleic Acid’s dispersing capabilities help prevent dye particles from aggregation, ensure uniform dyeing results, reduce suspended solids in wastewater discharged, as well as maintaining pigment particle stability and avoiding precipitation and stratification thereby improving product quality.

Polymaleic Acid’s application in construction primarily takes form in cement and concrete modification; adding it can improve fluidity of cement slurry, reduce viscosity, increase construction efficiency and extend service life of building structures; as a mortar additive it can improve crack resistance, durability and service life of structures. Furthermore, in agriculture Polymaleic Acid can be found used as an ingredient for formulation of pesticides and liquid fertilizers so as to increase uniform spraying uniformity while simultaneously dispersing active ingredients to avoid solid precipitation ensuring drug efficaciency stability.

Polymaleic Acid has become an indispensable tool in meeting increasingly stringent environmental protection regulations, while also branching out into various new fields. Saline-alkali soil improvement uses it to disperse particles, break up compacted structures and increase air permeability and water retention; its biocompatibility makes it an attractive candidate material for thickeners and stabilizers in cosmetics industry; these cross-field applications prove its versatility and technical ductility.

Polymaleic Acid stands out as an attractive competitor due to its superior chemical and physical stability, both during high temperature (above 330) and alkaline environments, where its molecular structure remains undamaged, maintaining scale inhibition performance unaffected compared with many traditional scale inhibitors such as polyacrylic acid. Polymaleic Acid’s mechanism of action combines “lattice distortion” and threshold effect: It interferes with crystallization by adsorbing on crystal surfaces; yet can inhibit scale layer growth at very low concentration (1-15 mg/L), making its use cost-effective and eco-friendly.

Polymaleic Acid’s environmental benefits are numerous. Certified as non-toxic by international standards and featuring biodegradability for easy disposal, Polymaleic Acid avoids risks associated with phosphorus-based scale inhibitors that could eutrophicate water bodies while fulfilling global requirements for green chemicals. Furthermore, its production process has been continuously optimized in line with environmental initiatives; promotion of solution methods reduces organic solvent usage for reduced carbon emissions and environmental pollution.

Polymaleic Acid’s synergistic effect in compound applications is especially notable. When combined with organic phosphonates, they work in synergy through different mechanisms of action (chelation and dispersion) for maximum scale inhibition rates of 98%; combined with zinc salts they form dense protective films which double corrosion inhibition efficiency; these flexible properties enable Polymaleic Acid to adapt easily to complex water conditions like industrial circulating water with both high hardness and alkalinity levels.

Economic benefits associated with Polymaleic Acid include its efficiency in terms of both dosage reduction and equipment maintenance costs. For instance, its scale inhibition effect in boiler systems has been estimated at 10-15% energy loss reduction while increasing service life by 3-4 years. Furthermore, its wide applicability (pH 2.0-8.3, temperature range 350+) makes operating easier as frequent adjustments no longer need to take place during operation process.

Polymaleic Acid has an extensive quality control system in place, as outlined by national standard GB/T 10535-2014, including rigorous regulations on key indicators like product appearance, solid content and bromine value to ensure batch stability. Enterprises can further ensure production compliance by attaining ISO three-system certification (quality, environment and occupational health and safety), providing reliable support for large-scale industrial applications.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polymaleic Acid

Polymaleic Acid Manufacturer

Contact Us

As an experienced Polymaleic Acid manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polymaleic Acid CAS 26099-99-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.