Oxydipropyl Dibenzoate CAS 27138-31-4

Factory wholesale Oxydipropyl Dibenzoate CAS 27138-31-4

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Oxydipropyl Dibenzoate

CAS: 27138-31-4

MOQ: 1KG

Directory Guidance on Oxydipropyl Dibenzoate

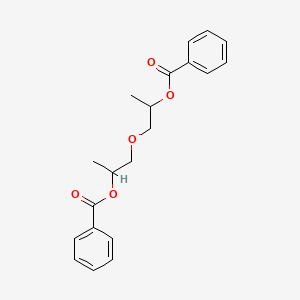

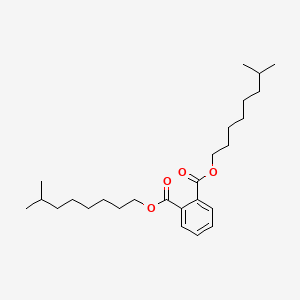

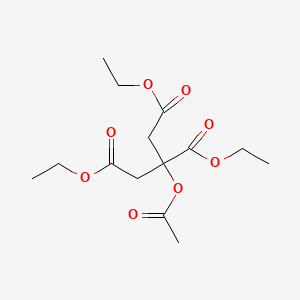

Chemical Structure

Basic Info:

| Melting Point | -40 |

| Boiling Point | 232 °C5 mm Hg(lit.) |

| Density | 1.12 g/mL at 25 °C(lit.) |

| Vapor Pressure | 0Pa at 25℃ |

| Refractive Index | n20/D 1.528(lit.) |

Oxydipropyl Dibenzoate Introduction:

Oxydipropyl Dibenzoate is a high-performance organic compound with a special molecular structure. Its chemical formula is C29H34O8 and its molecular weight is approximately 534.58 g/mol. This substance is formed by connecting two benzoic acid groups through polypropylene glycol segments. Its molecular structure simultaneously contains a rigid benzene ring and a flexible ether bond. This combination of rigidity and flexibility makes it show unique application potential in the field of materials science.

From the perspective of microstructure, the ester group functional group at the end of the Oxydipropyl Dibenzoate molecule endows the material with good reactivity, while the polypropylene glycol chain segment in the middle provides excellent flexibility and low-temperature resistance. This structural combination enables it to form stable interactions with various polymer matrices.

In terms of physicochemical properties, Oxydipropyl Dibenzoate usually presents as a transparent to pale yellow viscous liquid or a low-melting-point solid at room temperature. Its melting point is adjustable within the range of -15 ° C to 25 ° C, depending on the degree of polymerization of the polypropylene glycol segments. Its density is approximately 1.08-1.12 g/cm³ (at 25℃), and the viscosity range is 500-5000 mPa·s (at 40℃). These physical parameters can be precisely regulated by changing the raw material ratio and synthesis process.

Oxydipropyl Dibenzoate has good solubility in common organic solvents such as acetone, toluene and ethyl acetate. Meanwhile, it shows excellent hydrolytic stability and thermal stability. Its thermal decomposition temperature can reach above 280℃, and it can still maintain structural stability under high-temperature processing conditions.

The industrial production of Oxydipropyl Dibenzoate mainly adopts the transesterification process, using dimethylpropane diol and benzoic anhydride as the main raw materials, and the polycondensation reaction is carried out under the action of acidic catalysts. The production process requires precise control of the reaction temperature (usually maintained at 180-220℃), vacuum degree (≤10 kPa), and catalyst dosage (0.1-0.5 wt%) to ensure uniform molecular weight distribution of the product.

In terms of safety and environmental characteristics, the toxicological assessment of Oxydipropyl Dibenzoate shows that its acute oral toxicity (LD50) is > 2000 mg/kg, which belongs to the actual non-toxic grade substance. Its biodegradability test shows that the degradation rate is less than 5% within 28 days, indicating its persistence in the natural environment but without causing bioaccumulation effects. According to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), this substance does not need to be marked with a hazard pictogram. However, it may release trace amounts of benzene series substances when handled at high temperatures.

Nature and Specifications:

| Item | Specification |

| Product Name | Oxydipropyl Dibenzoate |

| CAS No. | 27138-31-4 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | >230 °F |

| Storage Temp. | Sealed in dry,Room Temperature |

| Form | Liquid |

| Water Solubility | 8.69mg/L at 20℃ |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Oxydipropyl Dibenzoate

As a key modifier for high-performance synthetic materials, Oxydipropyl Dibenzoate plays an important role in the field of polymer processing. In the production of polyurethane elastomers, when used as a chain extender, this substance can significantly improve the tear strength and resilience of the material. The benzene ring structure in its molecule can effectively enhance the ordered arrangement of the hard segment phase region, while the flexible chain segment promotes the formation of microphase separation structure.

This dual effect enables the modified polyurethane products to maintain stable mechanical properties in a wide temperature range of -40℃ to 120℃, and is particularly suitable for the manufacture of automotive suspension parts, industrial seals and other parts with strict temperature tolerance requirements. In the field of polyvinyl chloride (PVC) processing, when Oxydipropyl Dibenzoate is used as a main plasticizer, compared with traditional phthalate plasticizers, it can not only provide considerable flexibility, but also significantly improve the product’s anti-migration and anti-extraction properties, which is particularly important for special application scenarios such as medical devices and food contact materials.

In the special coatings industry, Oxydipropyl Dibenzoate, with its excellent film-forming property and weather resistance, is widely used in high-end fields such as Marine coatings and protective coatings for wind turbine blades. As a reactive thinner, it can not only reduce the viscosity of the system and improve the construction performance, but also form a three-dimensional cross-linked network by participating in the curing reaction, thereby increasing the salt spray resistance of the coating by more than 30%.

In the UV curing system, the benzene ring structure in the Oxydipropyl Dibenzoate molecule can effectively absorb UV energy and reduce the photodegradation phenomenon during the curing process. Combined with the flexibility of the polypropylene glycol chain segment, the coating has the dual advantages of high hardness and impact resistance. In the field of electronic packaging materials, its low dielectric constant (ε=2.8-3.2 at 1 MHz) and low dielectric loss (tanδ<0.005) make it an ideal choice for high-frequency substrate materials for 5G communication equipment, which can effectively reduce signal transmission loss.

The adhesive industry makes full use of the dual reaction characteristics of Oxydipropyl Dibenzoate to develop high-performance structural adhesives. In epoxy resin system, after it is introduced as a flexible modifier, the elongation at break of the cured product can be increased from 2% to more than 15%, while maintaining the tensile strength at 40 MPa. This rigid-flexible balance makes it an important application in aerospace composite bonding, building structure reinforcement and other fields.

In hot melt adhesive formulas, the low crystallinity of Oxydipropyl Dibenzoate can effectively extend the open time, and with the rapid wetting ability of the polypropylene glycol segment, the bonding strength can be quickly established during the cooling process, which is particularly suitable for the high-speed bonding requirements of automated production lines. In the field of pressure-sensitive adhesives, by adjusting the addition ratio of this substance, the storage modulus (G’) and loss factor (tanδ) of the colloid can be accurately controlled, achieving performance regulation from permanent bonding to removable bonding.

The Advantages Of Oxydipropyl Dibenzoate

Compared with traditional plasticizers and modifiers, the core advantage of Oxydipropyl Dibenzoate is first reflected in its excellent thermal stability. The stable benzene ring structure and ether bond combination in its molecular structure make its thermal decomposition temperature more than 50°C higher than that of phthalate products. After long-term heat aging at 180°C for 1,000 hours, the volatility loss rate is less than 1.5%. This feature is irreplaceable in high-temperature application scenarios such as wires and cables and engine compartment components.

The unique molecular design of Oxydipropyl Dibenzoate also gives the material excellent cold resistance. It still maintains good flexibility in the low-temperature test of -50°C, overcoming the defect of traditional plasticizers that are easy to become brittle at low temperatures. This wide temperature range adaptability significantly expands the application range of modified materials.

From the perspective of economic benefits, although the initial cost of Oxydipropyl Dibenzoate is 20-30% higher than that of traditional materials, its long-term performance can extend the service life of the product by 2-3 times, and the full life cycle cost is reduced by more than 15%.

In the field of lightweight automobiles, plastic parts modified with Oxydipropyl Dibenzoate can reduce weight by 30% while maintaining the same mechanical properties, which is of great value to the improvement of the cruising range of new energy vehicles. In the electronics and electrical industry, its dielectric performance advantage can reduce signal transmission loss by 0.2 dB/cm, which means a significant technological breakthrough for scenarios such as 5G base station construction and high-speed data transmission equipment.

Environmental performance is another outstanding advantage of Oxydipropyl Dibenzoate. Its molecular structure does not contain controlled substances such as halogens and heavy metals, and meets the strict requirements of REACH regulations and RoHS directives. Acute toxicity experiments show that its safety threshold is two orders of magnitude higher than that of traditional phthalate plasticizers, and it has significant competitive advantages in sensitive fields such as medical devices and children’s products.

In terms of sustainable development, clean process technology is used in the production of Oxydipropyl Dibenzoate, which reduces unit product energy consumption by 25% compared with traditional processes, reduces three waste emissions by 40%, and can achieve chemical recovery through catalytic cracking, with a recycling rate of more than 85%. These characteristics perfectly match the current policy orientation of circular economy development.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Oxydipropyl Dibenzoate

Oxydipropyl Dibenzoate Manufacturer

Contact Us

As an experienced Oxydipropyl Dibenzoate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Oxydipropyl Dibenzoate CAS 27138-31-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.