Oleamide CAS 301-02-0

Factory wholesale Oleamide CAS 301-02-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Oleamide

CAS: 301-02-0

MOQ: 1KG

Directory Guidance on Oleamide

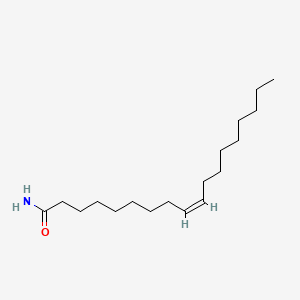

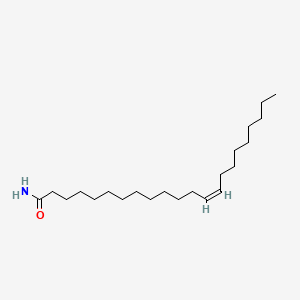

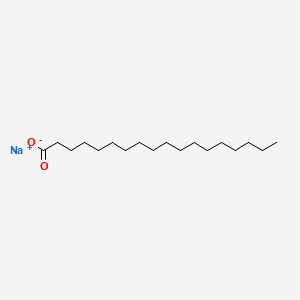

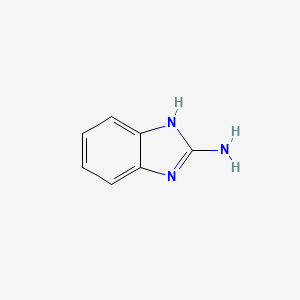

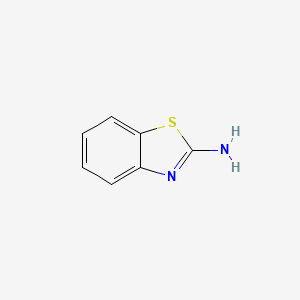

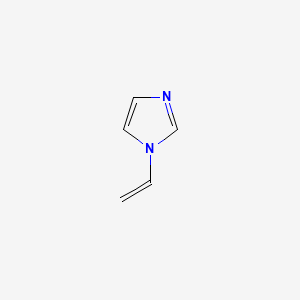

Chemical Structure

Basic Info:

| Melting Point | 70°C |

| Boiling Point | 433.3±24.0 °C(Predicted) |

| Density | 0.94 g/cm3 |

| Storage Temp. | -20°C |

Oleamide Introduction:

Oleamide is an organic compound with important industrial value, chemical name cis-9-octadecenamide, molecular formula C ₁₈ H ∝₅ NO, CAS number 301-02-0. Its molecular structure is composed of long-chain oleic acid groups combined with amide groups, and this unique configuration endows it with excellent surface activity and lubrication properties.

From a physical perspective, Oleamide appears as a white or light yellow waxy solid at room temperature, with a melting point of 75-85 ℃. It is insoluble in water but soluble in organic solvents such as ethanol and acetone. This hydrophobic and oleophilic property makes it perform well in various industrial scenarios, especially in fields that require reducing material surface friction or improving interface compatibility, making it irreplaceable.

In terms of preparation process, Oleamide is mainly synthesized by reacting oleic acid with ammonia or urea under high-temperature catalytic conditions. In recent years, with the popularization of green chemistry concepts, some enterprises have begun to use bio based raw materials to replace traditional petroleum based oleic acid, improve product purity through environmentally friendly processes such as enzyme catalysis, and reduce carbon emissions during the production process.

This technological innovation not only responds to the call for global sustainable development, but also provides higher quality raw material guarantees for downstream application fields. It is worth noting that Oleamide has high chemical stability and is not easy to oxidize and decompose under normal storage conditions, but it needs to avoid long-term exposure to strong acid, strong alkali or ultraviolet environment to prevent molecular chain breakage and affect performance.

Oleamide has earned high praise as both environmentally friendly and user-safe chemical material, meeting EU REACH regulation and Globally Harmonized System of Classification and Labelling of Chemicals (GHS) standards for safety and environmental friendliness. Biodegradation studies demonstrate its potential decomposition into carbon dioxide and water through natural environment decomposition through microbe action without producing persistent pollution; such qualities make Oleamide widely utilized in areas requiring higher safety requirements such as food packaging or medical devices.

Nature and Specifications:

| Item | Specification |

| Product Name | Oleamide |

| CAS No. | 301-02-0 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Pka | 16.61±0.40(Predicted) |

| Form | Solid |

| Color | White to off-white |

| Water Solubility | Insoluble in water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Oleamide

Oleamide holds an integral place in the plastic processing industry as an effective high-performance additive. By adding just 0.1%-1% Oleamide to resin systems like polyethylene and polypropylene resins, its use can significantly decrease melt viscosity, improve extrusion efficiency and decrease equipment energy consumption. Furthermore, its migration towards material surfaces also gives products enhanced demolding performance–especially high gloss injection molded ones which eliminate flow marks while improving surface smoothness–while on blown film products it prevents adhesion while increasing anti-static effect–this feature being particularly advantageous for electronic component packaging films that may contain electronic component packaging films.

Oleamide is widely utilized within the rubber industry as an internal lubricant and anti sticking agent. When mixing rubber material, Oleamide helps reduce frictional resistance between it and chamber walls of an internal mixer, promote uniform dispersion of fillers, and ultimately enhance mechanical properties of vulcanized rubber products. Furthermore, tire manufacturing processes that utilize multi-layer rubber composites benefit greatly from using this additive to help prevent adhesion between semi-finished components, increase molding efficiency, prevent interlayer adhesion between semi-finished components as well as improve molding efficiency; in production of seals this additive improves demolding effects by reducing surface defects while simultaneously increasing service life of molds.

Oleamide finds many applications in coatings and inks. When applied as a leveling agent in solvent based coatings, Oleamide can help improve surface tension distribution and eliminate defects such as orange peeling or shrinkage; when added to aqueous systems it enhances pigment wetting properties for uniform coloring, UV curable ink curing shrinkage rate adjustments, edge warping prevention, UV curing shrinkage rate adjustments as well as slow release properties to extend protection periods in special ship antifouling paints like ship antifouling paints.

Oleamide’s popularity in the daily chemical industry can mainly be found within personal care products, specifically hair conditioners and moisturizers. When added to these formulas, it provides a breathable protective film over skin or hair surface with smooth touch feel and moisturizing function, improving powder dispersion and makeup fit; with recent trend of silicone free cleaning products becoming more widely adopted; Oleamide has shown great promise as natural source conditioner replacing organosilicon.

Oleamide is widely utilized within the textile industry as the core component of spinning oil, providing a uniform lubricating layer on fiber surfaces while simultaneously decreasing frictional coefficients between spinning process and guide wire, decreasing yarn breakage rates, and producing ultrafine fibers more easily. Furthermore, for ultrafine fiber production precise oiling agent formulas can effectively control electrostatic adsorption between monofilaments which ensure smooth weaving progress and post-treatment softeners containing it can impart long-term silky hand feel with breathability or color fastness issues.

The Advantages Of Oleamide

Oleamide stands out as an exceptionally versatile chemical property from an engineering viewpoint due to its customisable molecular structure. By altering carbon chain length or adding modification groups, its compatibility with different substrates can be tailored precisely and targetedly; for instance, increasing proportion of amide groups or lengthening carbon chain structure are both effective ways of increasing interfacial interaction; in non-polar rubber systems extending carbon chain structure increases migration efficiency. Such molecular level controllability gives Oleamide the flexibility and control needed to meet complex and changeable industrial demands, giving traditional additives one function or another distinct advantages over traditional additives with single functions.

Application compatibility is another core competitiveness of it. Oleamide can form a synergistic effect with most polymer additives. For instance, when used in combination with antioxidants, it can delay self-oxidation, and when used in conjunction with fillers, it can enhance the uniformity of dispersion. In complex formulation systems, it neither reacts with acidic stabilizers nor interferes with the efficacy of light stabilizers. This “friendly” additive feature greatly simplifies the development difficulty for formula engineers and is particularly suitable for the design of composite materials that need to take into account multiple performance requirements.

In terms of economy, the unit efficiency cost advantage of Oleamide is prominent. Take plastic processing as an example. An addition of 0.5% can achieve a modification effect of 1.2% of traditional stearic acid lubricants, which means that raw material consumption is reduced by 40% under the same output. In the rubber mixing process, it can shorten the mixing time by 15% to 20%, directly reducing energy consumption and labor costs. What is more worth mentioning is that its migration speed in the product is controllable and will not affect the appearance of the product due to excessive exudation, which reduces the additional expenditure of subsequent surface treatment processes.

Considering the convenience of use, the physical form of Oleamide is similar to that of conventional resin particles and can be directly added to the extruder through the main feeding port without the need for dedicated premixing equipment. Its melting temperature is highly consistent with the general plastic processing temperature range (180-240℃), and molecular-level dispersion can be achieved during the melt blending process. For precision injection molding scenarios that require precise measurement, the particle size distribution range can be customized to 50-100μm, ensuring excellent batch stability even with trace additions.

In terms of environmental protection attributes, Oleamide has a relatively low environmental load throughout its entire life cycle. Its raw material, oleic acid, can be extracted from renewable vegetable oils. The production process adopts a closed-loop circulation technology, and the discharge of three wastes is reduced by more than 30% compared with similar products. Compared with fluorine-containing compounds or organosilicon lubricants, the bioaccumulation index (BCF) of Oleamide is only 0.02, and its ecotoxicity is significantly reduced. This enables it to maintain a stable market access qualification under strict regulatory systems such as the EU’s Regulation on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH).

Contact Us

Product Package picture:

Related References:

chemicalbook-Oleamide

Oleamide Manufacturer

Contact Us

As an experienced Oleamide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Oleamide CAS 301-02-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.