Lead Tetraacetate CAS 546-67-8

Factory wholesale Lead Tetraacetate CAS 546-67-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Lead Tetraacetate

CAS: 546-67-8

MOQ: 1KG

Directory Guidance on Lead Tetraacetate

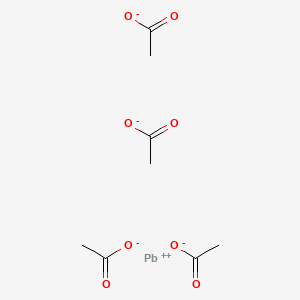

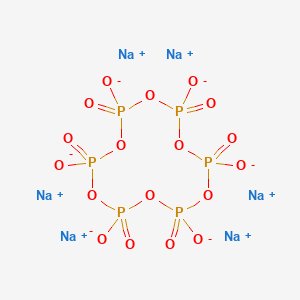

Chemical Structure

Basic Info:

| Melting Point | 175-180 °C |

| Boiling Point | 118.1°C |

| Density | 2,28 g/cm3 |

| Storage Temp. | Inert atmosphere,2-8°C |

Lead Tetraacetate Introduction:

Lead Tetraacetate is an important organometallic compound with the chemical formula Pb(CH3COO)4. It is a white or light yellow crystalline powder at room temperature. This compound is relatively stable in a dry environment, but because its molecule contains a high oxidation state of lead (+4 valence), it easily absorbs moisture in the air and undergoes hydrolysis reaction to produce products such as acetic acid and lead dioxide.

In the crystal structure of Lead Tetraacetate, the lead atom is located in the center and is bound to four acetate groups through coordination bonds to form a tetrahedral configuration. This unique structure gives it excellent oxidation ability and coordination characteristics, making it play an irreplaceable role in specific chemical reactions.

From the perspective of the synthesis process, Lead Tetraacetate is usually prepared by reacting lead oxide with glacial acetic acid under heating conditions. The temperature and time parameters need to be strictly controlled during the reaction to avoid the formation of by-products. Industrial-grade products usually contain a small amount of free acid and water, while high-purity reagents need to undergo multiple recrystallization and vacuum drying processes.

It is worth noting that the compound is extremely sensitive to humidity and temperature during storage and needs to be sealed and stored under inert gas protection. Special attention should be paid to protective measures during laboratory operations, because both its dust and solution are toxic and may cause damage to the nervous system and hematopoietic system.

In terms of physical and chemical properties, the melting point of Lead Tetraacetate is about 175-180℃, but in practical applications, it often decomposes at lower temperatures. Its solubility shows significant characteristics: it is easily soluble in organic solvents such as glacial acetic acid, benzene, and chloroform, but its solubility in water is extremely low. This solubility property makes it particularly suitable for use as an oxidant in non-aqueous systems.

Spectral analysis shows that the lead-oxygen bond in its molecule has a strong polarity, which directly determines its high efficiency in electron transfer reactions. In addition, the thermogravimetric analysis curve of Lead Tetraacetate shows that the acetic acid group will be gradually lost above 120℃, and lead oxide residues will eventually be generated.

Nature and Specifications:

| Item | Specification |

| Product Name | Lead Tetraacetate |

| CAS No. | 546-67-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Solubility | Chloroform, Methanol (Slightly) |

| Form | Crystalline Powder |

| Color | White to light orange-pink |

| Specific Gravity | 2.28 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Lead Tetraacetate

As a strong oxidant, Lead Tetraacetate has unique value in the field of organic synthesis. Its oxidation ability is between that of lead dioxide and peroxy acid, making it particularly suitable for certain specific types of oxidation reactions. For example, in the cleavage reaction of adjacent diols, it can selectively cleave carbon carbon bonds without affecting other functional groups. This selectivity comes from the synergistic effect of its steric hindrance effect and electronic effect.

In metal organic chemistry, Lead Tetraacetate often participates in complex reactions as a ligand, and its strong coordination ability can effectively stabilize the structure of intermediates. These characteristics make it an important tool in the design of complex molecular synthesis routes.

In the field of industrial applications, Lead Tetraacetate is mainly used as a high-performance oxidant in the production of fine chemicals. Its high oxidation efficiency and few by-products have obvious advantages in the preparation of dye intermediates and drug precursors. Lead Tetraacetate is used as a catalyst in some special types of epoxy resin curing systems because it can accurately control the curing reaction process.

In analytical chemistry, this compound is used as a colorimetric reagent for specific elements, and trace detection is achieved by forming characteristic complexes with the target. Although stricter environmental regulations in recent years have restricted some of its applications, it still maintains an important position in some irreplaceable process links.

Research in materials science has demonstrated the utility of Lead Tetraacetate as a precursor in creating functional materials, such as lead oxide materials with specific crystal forms that perform well for photoelectric conversion and piezoelectric sensing applications. Furthermore, trace amounts of Lead Tetraacetate added during polymer modification can significantly enhance thermal stability and mechanical strength for enhanced material performance.

In addition, in the development of new battery systems, researchers are exploring its possibility as an electrode additive, using its unique redox properties to improve battery performance. These exploratory applications have opened up new development space for Lead Tetraacetate.

Pharmaceutical research and development professionals must tread lightly when using Lead Tetraacetate; however, its use remains essential in certain specific drug synthesis routes – for instance in creating antibiotics using certain key steps where lead oxidant molecules play an essential role as oxidants. Pharmaceutical companies utilize strict process controls to ensure that any lead residue found in their final products meets international standards.

Lead Tetraacetate compounds have long been utilized as tracer research compounds, and its chemical stability ensures reliable experimental data collection. Even as pressure mounts to develop alternatives to its strategic position in this field, its place will likely remain difficult to dislodge within an acceptable timeframe.

The Advantages Of Lead Tetraacetate

The outstanding advantages of Lead Tetraacetate are first reflected in its unique selective oxidation ability. Compared with other oxidants, it can precisely act on specific functional groups without affecting other parts of the molecule. This selectivity comes from the synergistic effect of the steric hindrance and electronic effects of its molecular structure, which makes the reaction highly specific.

In the later modification of complex molecules, this characteristic can significantly improve the economy and feasibility of the synthesis route. At the same time, its oxidation product is usually an easy-to-handle lead acetate byproduct, which simplifies the post-processing process. This comprehensive advantage makes it a preferred reagent in multi-step synthesis routes.

In terms of reaction efficiency, Lead Tetraacetate can start highly active reactions under mild conditions. Most oxidation reactions using this reagent can be completed in the range of room temperature to 80°C, and the energy consumption is significantly lower than the traditional process that requires high temperature and high pressure. The reaction time is usually controlled within a few hours, and the conversion rate can reach more than 90%.

This high efficiency not only improves production efficiency, but also reduces energy consumption and carbon emissions. Especially in reactions involving sensitive substrates, its mild reaction conditions can effectively protect easily decomposable functional groups, which is an advantage that other strong oxidants cannot achieve.

Continuous improvement of environmental performance is the key to Lead Tetraacetate’s competitiveness. Modern production processes have reduced lead emissions in the production process by more than 90% through closed reaction systems, solvent recovery technology and other means. The development of new stabilizers has significantly extended the product shelf life and reduced waste caused by deterioration.

On the application side, chemists have developed a matching lead ion capture technology to ensure that the lead content in the reaction wastewater meets the emission standards. These technological advances have effectively resolved the environmental risks of traditional lead compounds and laid the foundation for their sustainable development.

In terms of cost-effectiveness, Lead Tetraacetate shows a good economic balance. Although the price per unit mass is higher than some alternatives, its high reactivity greatly reduces the actual feed amount. The maturity of large-scale production technology has led to a continuous decline in the cost of industrial-grade products, and the current market price has been reduced by about 40% compared with ten years ago.

What is more noteworthy is that the use of this reagent can usually shorten the process flow and improve the purity of the product, thereby bringing comprehensive cost advantages. In the production of fine chemicals, this cost advantage can be converted into significant market competitiveness. With the advancement of recycling technology, its recycling economy will be further improved.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Lead Tetraacetate

Lead Tetraacetate Manufacturer

Contact Us

As an experienced Lead Tetraacetate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Lead Tetraacetate CAS 546-67-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.