Lauroyl Peroxide CAS 105-74-8

Manufacturer Lauroyl Peroxide CAS 105-74-8

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Lauroyl Peroxide

CAS: 105-74-8

MOQ: 1KG

Directory Guidance on Lauroyl Peroxide

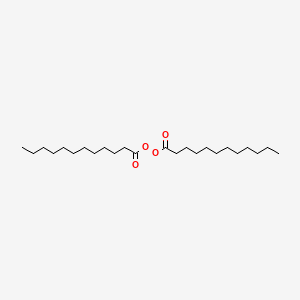

Chemical Structure

Basic Info:

| Melting point | 53-57 °C(lit.) |

| Boiling point | 441.76°C (rough estimate) |

| density | 0,91 g/cm3 |

| vapor density | 13.7 (vs air) |

| vapor pressure | 0Pa at 20℃ |

Product Introduction:

Lauroyl Peroxide, with the chemical formula C24H46O4, and molecular weight 398.62 is an important organic peroxide with a melting point between 53degC and 57degC, as well as decomposition temperatures between 70degC to 80degC. Lauroyl Peroxide can easily dissolve in organic solvents like acetone, chloroform, mineral oils etc; but cannot dissolve in water itself. While relatively stable at room temperatures it should be handled carefully during storage or use to prevent explosion.

Lauroyl Peroxide can be made by reacting dodecanoyl chloride with hydrogen peroxide in petroleum ether, adding sodium hydroxide, and finally hydrogen peroxide for oxidation reaction. Once complete, its final product can be obtained through cooling, stirring, filtering, and washing steps before use as an efficient free radical initiator. Typical composition includes an active oxygen content of around 4.02 percent with high activation energy that makes this an efficient free radical initiator.

Lauroyl Peroxide has numerous industrial applications. Primarily, it serves as an initiator of free radical polymerization reactions and can be seen widely used in producing polymers like polyvinyl chloride and high-pressure polyethylene. Furthermore, Lauroyl Peroxide may also be employed as a cross-linking agent for unsaturated polyesters, cross-linking agent for rubber, foaming agent, bleaching agent or cross-linking agent (crosslinker), foaming agent or bleaching agent (food industry and oil production). Finally it may even serve to improve appearance and quality.

Lauroyl Peroxide can be found in many industries and food fields, yet due to its oxidizing and potentially hazardous properties it must be handled carefully when used or stored. As it falls under primary organic oxidant classification and dust has an extremely irritating effect on eyes, skin, mucous membranes and can even lead to burns; Lauroyl Peroxide must also be packaged and transported according to regulations to ensure the safest delivery experience possible.

Nature and Specifications:

| Item | Specification |

| Product Name | Lauroyl Peroxide |

| CAS No. | 105-74-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| refractive index | 1.4460 (estimate) |

| storage temp. | 2-8°C |

| solubility | Chloroform (Slightly), DMSO (Slightly, Sonicated) |

| form | Powder |

| color | White |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the field of polymer synthesis, Lauroyl Peroxide occupies an important position as a free radical initiator. Its moderate decomposition temperature makes it particularly suitable for bulk polymerization and solution polymerization processes, especially in the synthesis of general plastics such as polyvinyl chloride (PVC) and polyethylene (PE), Lauroyl Peroxide can effectively regulate the polymerization reaction rate and molecular weight distribution. Compared with azo initiators, the free radicals produced by its decomposition have higher reactivity, which enables faster polymerization rates at the same addition amount. At the same time, the residual lauric acid by-product can also play an internal lubricating role and improve the processing performance of the final product. In recent years, with the growth of demand for special polymer materials, its application ratio in high-end fields such as functionalized polyolefins and modified engineering plastics has continued to rise.

The rubber processing industry is another important application scenario for Lauroyl Peroxide. Especially in silicone rubber processing, it has become a key auxiliary agent for the preparation of high-strength transparent silicone products due to its good compatibility with siloxane matrix.

In the field of fine chemicals, the oxidation properties of Lauroyl Peroxide have been innovatively applied.The food packaging materials industry uses its controllable decomposition characteristics to develop a coating system with self-sterilization function. This versatility makes Lauroyl Peroxide show unique value in emerging fields such as surface treatment and special coatings.

The pharmaceutical and daily chemical industries continue to deepen their exploration of the application of Lauroyl Peroxide. In drug synthesis, it participates in the preparation process of certain antibiotic intermediates as a free radical initiator, which has the advantages of mild reaction conditions and high product purity compared with traditional methods. Cosmetic formulators use the slow-release oxidation characteristics of Lauroyl Peroxide to develop an anti-acne ingredient carrier system with controlled release function. It should be pointed out that these applications are based on a strict quality control system to ensure that the final product meets the health and safety standards of the relevant industry.

With the popularization of the concept of green chemistry, the role of Lauroyl Peroxide in the development of environmentally friendly materials has become increasingly prominent. In the synthesis of biodegradable plastics, Lauroyl Peroxide as an initiator can ensure polymerization efficiency without introducing difficult-to-degrade metal residues. In the field of chemical recycling of waste polymer materials, its controllable decomposition characteristics are used in selective chain breaking technology to achieve efficient conversion of polymers to monomers.

The core competitiveness of Lauroyl Peroxide is first reflected in its excellent thermal response characteristics. By precisely controlling the process conditions, Lauroyl Peroxide can achieve continuous release of free radicals within a predetermined temperature range. Compared with traditional initiators such as dibenzoyl peroxide, its decomposition activation energy is more moderate, which not only avoids the problem of low-temperature storage, but also does not require excessively high reaction temperatures, which has significant advantages in reducing energy consumption. This balance makes it the preferred initiator for many polymerization processes.

From the perspective of reaction mechanism, the free radicals produced by the decomposition of Lauroyl Peroxide have a higher initiation efficiency, which enables it to achieve a faster reaction rate at the same molar concentration. This high efficiency is directly converted into a reduction in production costs, especially in large-scale continuous production, where shortening the reaction time means an increase in equipment utilization and a decrease in energy consumption. At the same time, its decomposition product lauric acid can continue to play a role as a processing aid. This “one dose, multiple effects” feature reduces the types and amounts of additional additives in the formula and simplifies the production process.

The breadth of product adaptability constitutes another significant advantage of Lauroyl Peroxide. In solvent systems with different polarities, Lauroyl Peroxide can maintain good solubility and reactivity. This universality allows it to be used in different media environments from oil-based coatings to water-based adhesives. When faced with complex formulation systems, it has good compatibility with common plasticizers and stabilizers and will not cause system stratification or performance degradation.

From the perspective of the whole life cycle cost, the process of using Lauroyl Peroxide is often accompanied by derivative benefits such as reduced energy consumption and reduced waste, which is of practical significance for meeting increasingly stringent environmental regulations. Especially in the field of electronic chemicals that require high-purity products, its low metal residue characteristics can significantly reduce post-processing costs.

Environmental friendliness is a key factor in the continued market recognition of this product. Unlike traditional heavy metal-containing initiators, the decomposition products of Lauroyl Peroxide do not contain toxic substances, and lauric acid, as a natural fatty acid component, can be quickly degraded by environmental microorganisms. Under the green product certification system, products using Lauroyl Peroxide as a processing aid are more likely to obtain eco-label certification, which is particularly important for export-oriented companies. With the improvement of clean production standards in the global chemical industry, this environmental compatibility advantage is being transformed into real market competitiveness.

Contact Us

Product Package picture:

Related References:

chemicalbook-Lauroyl Peroxide

Lauroyl Peroxide Manufacturer

Contact Us

As an experienced Lauroyl Peroxide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Lauroyl Peroxide CAS 105-74-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.