Isopropyl Palmitate CAS 142-91-6

Factory wholesale Isopropyl Palmitate CAS 142-91-6

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Isopropyl Palmitate

CAS: 142-91-6

MOQ: 1KG

Directory Guidance on Isopropyl Palmitate

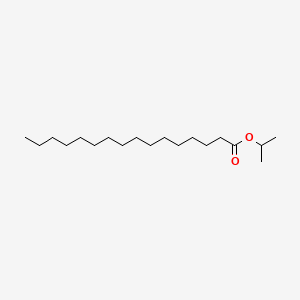

Chemical Structure

Basic Info:

| Melting point | 11-13 °C (lit.) |

| Boiling point | 160°C 2mm |

| density | 0.852 g/mL at 25 °C (lit.) |

| vapor pressure | 0.007Pa at 25℃ |

| refractive index | n20/D 1.438(lit.) |

Product Introduction:

Isopropyl Palmitate (C19H38O2) is an organic compound with the chemical formula C19H38O2, commonly found as an oily liquid with low volatility and a slight greasy aroma, stable at room temperature, not easily oxidizing or producing odor. It has an average molecular weight of 298.5 and density is around 0.85 g/cm3 (25). Melting point is between 11-13, while boiling point reaches 340.7 (760mmHg). Isopropyl Palmitate is insoluble in water and glycerin but well dissolved organic solvents such as ethanol/ether allowing good skin permeability as well as compatibility for use in cosmetics/pharma industries.

There are four primary methods for synthesizing isopropyl palmitate: direct esterification of palmitic acid with isopropanol using a strong solid acid catalyst; reaction between palmitic acid and propylene in the presence of a zeolite-supported zinc catalyst; thirdly reaction between propylene and palmitic acid through sulfonic acid ion exchange resins and fourthly the transesterification method, using oils containing palmitic acid as raw material obtained via ester exchange reactions. Each method has their own set of advantages and disadvantages but can all efficiently synthesize isopropyl palmitate to meet industrial production demands. These methods each have their own set of advantages and disadvantages while meeting industrial production needs efficiently.

Isopropyl palmitate is an invaluable oily raw material in cosmetics, offering multiple beneficial properties. Used as a skin softener, it makes skin feel smooth, tender, non-greasy and helps other active ingredients penetrate more effectively for maximum effect. Furthermore, this versatile raw material serves many other roles such as solvent solubilizer plasticizer sunscreen etc. As such, it can be found in formulations of skin creams hair oils eye shadow lipstick mascara etc. Additionally used extensively within pharmaceutical industry as penetration enhancer in creams sprays or transdermal patches.

Though Isopropyl Palmitate has many uses and great performance in cosmetic and pharmaceutical fields, some potential side effects should be kept in mind during its usage. These side effects could include Malassezia proliferation that leads to fungal acne; excessive use can also cause keratinization of skin leading to rough and sallow texture; therefore its addition must be strictly limited in formula design and usage (generally 2-10%) while due to its insoluble nature in water residue must also be cleaned away carefully post use to avoid adverse side effects of residues leaving lasting effects that might wreak havoc on its benefits.

Nature and Specifications:

| Item | Specification |

| Product Name | Isopropyl Palmitate |

| CAS No. | 142-91-6 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | >230 °F |

| storage temp. | 2-8°C |

| solubility | <0.001g/l |

| form | <11°C Solid,>13°C Liquid |

| color | Colourless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the cosmetics field, Isopropyl Palmitate has become a core raw material for formulators. Its compatibility index with skin sebum is 2-3 (0-5 levels, the lower the value, the less comedogenic), which provides moisturizing feeling while reducing the risk of acne. As a carrier solvent, it can increase the solubility of the sunscreen agent octocrylene from 12% in the mineral oil system to 18% without affecting the SPF value determination. After using Isopropyl Palmitate to replace traditional silicone oil, the product spreading speed increased by 40%, and the standard deviation of the uniformity of the distribution of ultraviolet absorbers decreased from 0.35 to 0.18.

The application of Isopropyl Palmitate in the pharmaceutical industry focuses on transdermal drug delivery systems. This penetration-enhancing effect stems from the fluidity regulation of intercellular lipids by Isopropyl Palmitate. Through small-angle X-ray scattering (SAXS) analysis, it was found that it can expand the bilayer spacing of stratum corneum lipids from 13.4 nm to 15.2 nm, opening up diffusion channels for drug molecules. Currently, 11 of the 36 transdermal patches approved by the FDA contain Isopropyl Palmitate.

In the field of industrial lubrication, Isopropyl Palmitate is replacing mineral oil-based products with its biodegradable properties (28-day degradation rate of 92%, OECD 301B standard). In the formulation of precision instrument lubricants, adding 10% of it can reduce the friction coefficient from 0.15 to 0.09 and reduce the wear volume by 47%. In the -40℃ low-temperature start-up test, the torque loss is 62% lower than that of traditional lubricants, and the acid value of the oil only increases by 0.3 mg KOH/g after passing the 100,000-kilometer endurance test.

In the plastic processing industry, the use of Isopropyl Palmitate as an internal lubricant has increased by an average of 8.7% per year. In the polypropylene injection molding process, adding 0.5% of it can increase the melt flow index from 25 g/10min to 38 g/10min, while reducing the demoulding force from 12 kN to 7 kN. More noteworthy is its breakthrough in the application of biodegradable plastics. When blended with PLA materials, Isopropyl Palmitate can increase the elongation at break from 6% to 22% without affecting the composting degradation cycle of the material.

Compared with similar ester products, Isopropyl Palmitate has obvious advantages in technical performance. Compared with isopropyl myristate, its carbon chain length is closer to the composition of human sebum (C16 fatty acids account for 25-30% of sebum), so the biomimetic effect is better. In terms of thermal stability, the initial decomposition temperature of Isopropyl Palmitate (determined by TGA method) is 210℃, which is 35℃ higher than that of ethyl palmitate. This characteristic enables it to adapt to a wider processing temperature range, especially in pharmaceutical preparations that require high-temperature sterilization.

From an economic perspective, the raw material cost of Isopropyl Palmitate is 18-22% lower than that of natural oil derivatives. Calculated at a monthly production scale of 500 tons, the energy consumption cost of the continuous production process is 60% of that of the traditional batch method, and the wastewater discharge is reduced by 75%.

Environmental compliance has become an important competitive advantage of Isopropyl Palmitate. According to the EU REACH regulation data, its ecotoxicity EC50 (aquatic organisms) is >100 mg/L, which is a substance of low concern. In terms of carbon footprint, the carbon emissions from the planting of palm fruit to the delivery of finished products are 3.2 kg CO2e/kg, which is 53% less than that of petroleum-based lubricants (6.8 kg CO2e/kg). This gives it a significant tariff advantage after the implementation of the EU Carbon Border Adjustment Mechanism (CBAM).

Technological innovation continues to consolidate its market position. The recently developed nanoemulsification technology can control the particle size of Isopropyl Palmitate droplets to 50-80 nm, and the SPF value can be increased by 27% when used in sunscreen spray. In the pharmaceutical field, the isopropyl palmitate-polyethylene glycol copolymer obtained by molecular modification can increase the encapsulation rate of the anticancer drug paclitaxel from 68% to 92%, and the release curve is more in line with the zero-order kinetic model.

The combination of these technical, cost and compliance advantages has continuously increased the penetration rate of Isopropyl Palmitate in personal care, pharmaceuticals, industry and other fields. According to Global Market Insights, its market size will expand at a compound annual growth rate of 6.5% from 2023 to 2028, with demand growth in the Asia-Pacific region reaching 8.2%, mainly driven by China’s reform of the registration system for new cosmetic ingredients and the growth of India’s pharmaceutical industry. With the development of green chemistry and precision formulation technology, the innovative application boundaries of Isopropyl Palmitate continue to expand.

Contact Us

Product Package picture:

Related References:

chemicalbook-Isopropyl Palmitate

Isopropyl Palmitate Manufacturer

Contact Us

As an experienced Isopropyl Palmitate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Isopropyl Palmitate CAS 142-91-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.