Hexane CAS 110-54-3

Factory wholesale Hexane CAS 110-54-3

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Hexane

CAS: 110-54-3

MOQ: 1KG

Directory Guidance on Hexane

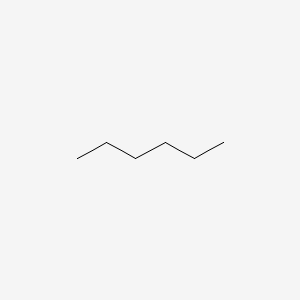

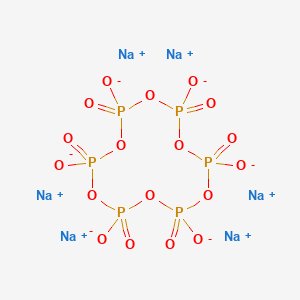

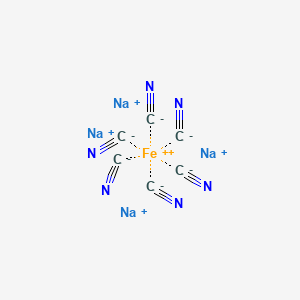

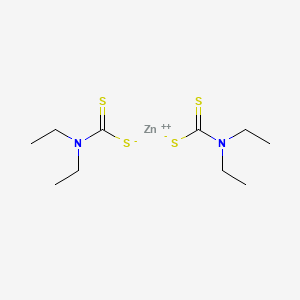

Chemical Structure

Basic Info:

| Melting point | -95 °C |

| Boiling point | 68.95 °C(lit.) |

| density | 0.659 g/mL at 25 °C(lit.) |

| vapor density | 3.5 (vs air) |

Hexane Introduction:

N-hexane is a common organic compound with the chemical formula C6H14. It is a colorless liquid at normal temperature and pressure. The melting point of n-hexane is -95 ℃, the boiling point is around 69℃, and the density is approximately 0.66g/cm³. This excellent solubility is one of the key foundations for its numerous applications. N-hexane can be obtained from the petroleum fractionation process, which is also a common way for its large-scale industrial production.

At normal temperature and pressure, Hexane appears as a colorless and transparent liquid with a faint odor similar to gasoline. Its boiling point is approximately 69℃, melting point is about -95℃, and its density is lighter than that of water, approximately 0.66g /cm³. This low boiling point characteristic makes it volatile at room temperature, with a vapor density higher than that of air, and it is easy to accumulate in a closed space to form a flammable mixture. In industry, it is mainly produced through petroleum fractionation or catalytic cracking processes, and can also be prepared by emerging technologies such as syngas Fischer-Tropsch synthesis or biomass conversion. Different production processes have a significant impact on the purity, impurity content and cost control of the product.

Hexane exhibits typical alkane inertness characteristics and is resistant to strong acids, bases and most oxidants at room temperature. Therefore, it mainly participates in free radical substitution reactions. For example, it can undergo halogenation reactions with halogens under light conditions. This chemical stability makes it of particular value in scenarios where inert solvents are required, but it also brings the risk of environmental retention.

In terms of safety, the explosion limit of Hexane vapor mixed with air is 1.2%-7.7% (by volume), and its flash point is as low as -22℃, making it a highly flammable substance. Long-term exposure may cause peripheral neuropathy. This neurotoxicity is closely related to the damaging effect of its metabolite 2, 5-hexanedione on nerve axons. In terms of environmental protection, as volatile organic compounds (VOCs), their emissions are strictly regulated, which prompts the industry to develop closed recycling systems and alternative solvent technologies.

Nature and Specifications:

| Item | Specification |

| Product Name | Hexane |

| CAS No. | 110-54-3 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| vapor pressure | 40 mm Hg ( 20 °C) |

| refractive index | n20/D 1.388 |

| Fp | 30 °F |

| storage temp. | Store at +5°C to +30°C. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Hexane

In the industrial production system, Hexane occupies a special position due to its excellent solubility. As a non-polar solvent, it exhibits strong solubility for organic compounds such as oils, resins, and rubber, making it a core medium in vegetable oil extraction processes. Modern oil processing enterprises commonly use the Hexane extraction method, which achieves a high oil extraction rate of up to 99% through multi-stage countercurrent extraction. Residual solvents can be recovered and recycled through precision distillation systems, significantly improving economic efficiency.

In the field of polymer synthesis, it serves as both the medium for the polymerization reactions of monomers such as propylene and ethylene and a key solvent for the post-treatment of polymers. Its low boiling point characteristic is conducive to the separation and purification of products. During the adhesive manufacturing process, Hexane optimizes product performance by adjusting the viscosity of the system and slowing down the curing speed. Its rapid evaporation feature plays a significant role in shortening the drying time.

The fine chemical and electronic industries have put forward higher requirements for the application of Hexane. In the pharmaceutical industry, it is used in key links such as the crystallization of active pharmaceutical ingredients and equipment cleaning. Its high purity feature can effectively prevent drug contamination. This electronic grade product has undergone deep purification treatment, with the metal ion content controlled at the ppb level, making it a core solvent for diluting photoresists and cleaning wafers in the manufacturing of semiconductor devices.

In laboratory settings, Hexane is not only a commonly used mobile phase composition for chromatographic analysis, but also an ideal solvent for infrared spectroscopy testing. Its low UV absorption characteristics have unique advantages in spectroscopic analysis. In the field of environmental protection technology, this product is used as an absorbent in oil and gas recovery systems, achieving efficient capture of volatile organic compounds through adsorption desorption processes. This technology has been widely applied in gas stations, oil depots, and other places.

The reliance on Hexane in the field of materials science continues to increase. During the preparation process of nanomaterials, it can effectively prevent the agglomeration of nanoparticles as a dispersion medium. In the synthesis of aerogel, its supercritical characteristics are used in the drying process to maintain the porous structure; When modifying polymer materials, the swelling effect of Hexane can promote the uniform distribution of additives.

These application scenarios impose strict requirements on indicators such as solvent purity, water content, and types of impurities, driving the continuous innovation of Hexane’s distillation technology. The testing industry uses it as a standard substance to calibrate analytical equipment such as gas chromatographs and mass spectrometers. Its clear gas chromatography retention value has become an important reference for qualitative analysis of compounds.

The Advantages Of Hexane

From the perspective of product performance, high-purity Hexane has a significant competitive advantage. Modern distillation technology combined with molecular sieve adsorption process can increase the purity to over 99.9%, and the content of key impurities such as benzene series and sulfides is controlled at the ppm level. This purity level ensures its reliable application in sensitive fields such as electronics and medicine.

The online monitoring system introduced in the production process regulates the distillation parameters in real time, ensuring a high degree of consistency among different batches of products. This is particularly important for continuous production processes that require stable solvents. In terms of stability, the strictly controlled moisture content (usually below 50ppm) effectively prevents hydrolysis reactions from occurring, and the addition of antioxidants extends the product’s storage period, avoiding quality deterioration caused by long-term storage.

The economic advantage is the key factor for Hexane to continuously maintain its dominant position in the market. Compared with special solvents, its raw material sources are extensive and the production process is mature. The scale effect significantly reduces the unit cost. The optimized design of the solvent recovery system keeps the loss rate below 0.5%, and the recycling times can reach more than 20 times, significantly reducing the comprehensive cost of the enterprise.

From an environmental perspective, although Hexane itself is classified as a VOC, the popularization of closed-loop production processes has reduced its emissions by over 80%, and breakthroughs in biodegradation technology have further lowered its environmental footprint. The improvement of safety performance is reflected in the improvement of packaging containers. Nitrogen sealing technology combined with barrier composite material packaging effectively reduces the risk of explosion and combustion during transportation and storage.

Technological innovation drives the continuous upgrading of Hexane products. The application of supercritical extraction technology reduces the content of residual aromatic hydrocarbons by two orders of magnitude, meeting the food-grade application standards. The introduction of nanofiltration membranes significantly improves the separation efficiency and reduces energy consumption by more than 30%. The integrated design of the catalytic oxidation device enables the immediate treatment of VOCs in the exhaust gas, with the emission concentration exceeding the environmental protection standards.

These technological advancements not only consolidate the advantages in traditional application fields but also expand the application space in emerging fields such as the preparation of electrolyte for new energy batteries and the production of biodiesel. The improvement in market recognition is reflected in the perfection of the quality certification system and the compliance certification of multiple standards such as ISO, ASTM, and USP, making it one of the benchmark solvents in the global supply chain.

Contact Us

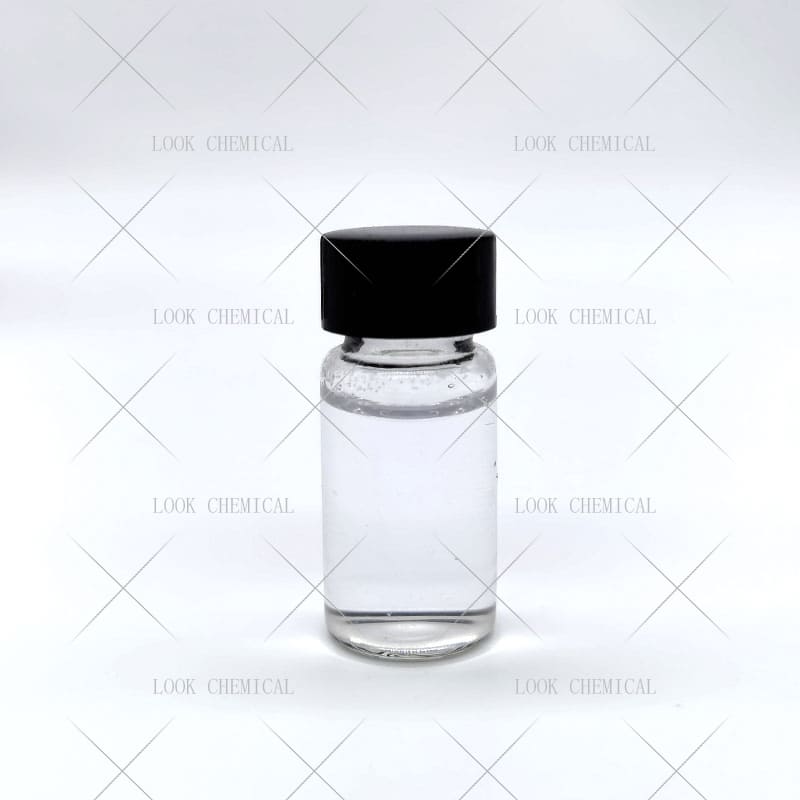

Product Package picture:

Related References:

chemicalbook-Hexane

Hexane Manufacturer

Contact Us

As an experienced Hexane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Hexane CAS 110-54-3 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.