Erucamide CAS 112-84-5

Factory wholesale Erucamide CAS 112-84-5

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Erucamide

CAS: 112-84-5

MOQ: 1KG

Directory Guidance on Erucamide

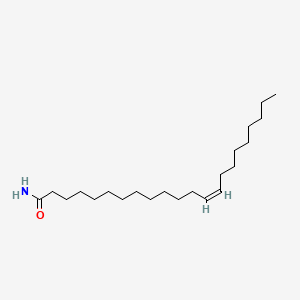

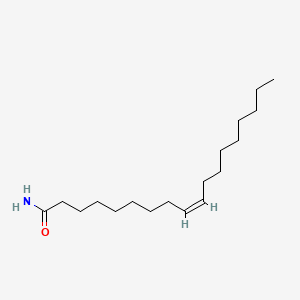

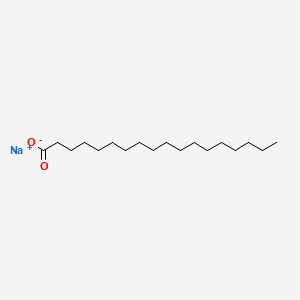

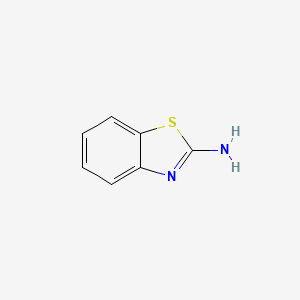

Chemical Structure

Basic Info:

| Melting Point | 75-85 °C 79-81 °C (lit.) |

| Boiling Point | 473.86°C (rough estimate) |

| Density | 0.9417 (rough estimate) |

| Vapor Pressure | 0-0Pa at 25℃ |

| Refractive Index | 1.5614 (estimate) |

Erucamide Introduction:

Erucamide is an organic compound generated by amidation reaction of erucic acid (a monounsaturated fatty acid, chemical name cis-13-docosaenoic acid) and ammonia, with a molecular formula of C₂₂H₄₃NO. The long carbon chain and polar amide groups in its molecular structure give it unique physical and chemical properties.

At room temperature, Erucamide is a white or light yellow crystalline powder or granules, with a melting point between 78-85°C, good thermal stability, and a decomposition temperature of more than 250°C. Due to the non-polar alkyl chain at the end of the molecular chain, it exhibits excellent solubility in most organic solvents, but is almost insoluble in water. This hydrophobicity gives it a significant advantage in specific applications.

From a chemical point of view, the amide group of Erucamide can form hydrogen bonds or coordination with the metal surface, showing a certain interfacial activity. At the same time, the long carbon chain structure enables it to be evenly dispersed in polymer materials in a molten state, reducing intermolecular friction. This dual characteristic allows it to be used as both a lubricant and a surface treatment agent. In industry, it is mainly prepared by reacting erucic acid with liquid ammonia under high temperature and high pressure. After the reaction, a high-purity product is obtained through crystallization, washing, drying and other processes, and the purity can usually reach more than 98%.

In terms of microscopic mechanism of action, the function of Erucamide depends on its mobility in the material system. During the plastic processing, as the temperature rises, it gradually migrates to the surface of the material to form a monolayer lubricating film. This dynamic migration characteristic enables it to ensure internal lubrication during processing and continuously provide later surface modification effects. Compared with short-chain amide compounds such as stearic acid amide, it has a longer carbon chain and weaker intermolecular forces, so the migration rate and lubrication efficiency are significantly improved.

From the perspectives of safety and environmental protection, the toxicological data of Erucamide indicate that it is a low-toxicity substance. It does not release harmful gases at normal processing temperatures and complies with the EU REACH regulation and FDA food contact material standards. These characteristics lay the foundation for its application in sensitive fields such as food packaging and medical devices.

Nature and Specifications:

| Item | Specification |

| Product Name | Erucamide |

| CAS No. | 112-84-5 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 230 °C |

| Storage Temp. | -20°C |

| Water Solubility | PRACTICALLY INSOLUBLE |

| Pka | 16.61±0.40(Predicted) |

| Form | solid |

| Color | Off-white |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Erucamide

Erucamide is widely utilized within the plastic processing industry as an efficient lubricant and mold release agent. When added at 0.1%-0.5% in production of polyethylene film, Erucamide reduces friction coefficient from 0.8 to below 0.2, significantly improving operational efficiency on automatic packaging lines. Furthermore, injection molding process using Erucamide reduces filling pressure by approximately 15% due to lower viscosity levels, thus also reducing silver streak defects on product surfaces as well as silver streaks on its surface. When adding 0.0%-0.2% Erucamide addition amounts can help avoid increasing haze while optical properties of optical products can remain intact.

Erucamide is used in the rubber industry as both a mold release agent and an anti-sticking agent, primarily as an inner tire lining formula additive to reduce peel force by 40% without altering bonding strength between rubber and cord. When producing EPDM rubber sealing strips, adding 0.3%-0.8% Erucamide helps combat surface roughness issues during extrusion while protecting finished products from adhering and deforming during storage and transportation.

Erucamide’s micronized products (with an approximate particle size D50 of approximately 5mm) are widely utilized as matting agents and wear-resistants in inks and coatings applications, including UV curable coating systems where an addition of 1-3% increases surface hardness by 1 to 2 hours while maintaining light transmittance above 85%. When added to flexographic printing inks during drying processes they create microconcave/convex surfaces which decrease gloss levels from 95GU down to 20-50GU in accordance with visual requirements set forth for different packaging materials.

Erucamide can be utilized as an ingredient of spinning oil agents in the textile industry to significantly lower dynamic friction coefficient and breakage rate for polyester filament, while increasing uniformity of coloration during spinning processes. When blended with polyurethane resin for functional coated fabrics, Erucamide forms a self-cleaning surface structure with over 120deg contact Angle; similarly when used as dispersant in chemical fiber masterbatches it significantly decreases Span of pigment particle size distribution from 1.8 to 0.7, improving uniformity significantly.

Emerging application fields include the modification of 3D printing consumables: PLA filaments with 0.1%-0.3%Erucamide added can significantly decrease extruder torque while improving interlayer bonding strength. When combined with ceramic particles, this product not only improves leveling properties but can also form porous structures at high temperatures that maintain air permeability within 300-500s/100cc range; similarly it has applications within biodegradable materials: used as processing aid in the PBAT/PLA blend system to increase elongation at break from 180% to 350%.

The Advantages Of Erucamide

Compared with traditional wax lubricants, Erucamide has significant molecular structure advantages. Its 22-carbon long chain has 4 more methylene units than stearic acid amide, and its molecular weight increases by about 15%. This structural difference increases the thickness of the surface adsorption film by 2-3 molecular layers, and the lubrication durability increases by more than 50%. The migration speed in polyolefin film is 30% slower than that of oleic acid amide, which means that the product can maintain a more stable friction coefficient during the storage cycle and avoid the problem of surface stickiness caused by excessive precipitation of lubricants in the later stage.

In terms of high temperature tolerance, the thermal decomposition temperature of Erucamide is 20℃ higher than that of behenic acid amide. In occasions such as PVC processing that require a processing temperature of 190-210℃, its thermal weight loss rate is controlled below 0.5%/h, which is far lower than the industry requirement of 1.5%/h. This thermal stability ensures that the functional effectiveness can be maintained in multiple processing or recycled material applications. For composite materials that require secondary processing, such as co-extruded films or multi-layer injection molded parts, Erucamide’s volatile organic compound (VOC) release is 90% lower than that of silicone release agents, meeting the VOC emission standards for automotive interior parts.

From the perspective of chemical inertness, the amide bond of Erucamide remains stable within the pH range of 3-11 and does not undergo hydrolysis reactions like ester lubricants. In polymer systems containing peroxide free radicals (such as cross-linked polyethylene), their antioxidant activity is 2-3 times higher than that of amine additives, and the yellowing index Δ YI can be controlled within 1.0. This chemical stability makes it particularly suitable for outdoor products with high weather resistance requirements, such as agricultural greenhouse films or automotive exterior parts.

The economic advantage is reflected in the efficiency of unit addition. Although the unit price of Erucamide is about 40% higher than that of calcium stearate, its effective addition concentration in LLDPE film is only one-third of the latter to achieve the same lubrication effect, and the overall cost can be reduced by 15% -20%.

In the post-processing stage of the product, the demoulding cycle of injection molded parts using Erucamide is shortened by 8%-12%. Calculated based on the annual production scale of tens of millions of pieces, the energy consumption cost can be saved by about 300,000 yuan per year. When the recycled materials are reused, the fluctuation range of the melt flow rate of HDPE containing Erucamide can still be controlled within ±10% after 5 times of melting and re-granulation, which is much better than the ±25% fluctuation of other types of lubricants.

In terms of environmentally friendly characteristics, the biodegradation rate (28 days) of Erucamide reaches 65%, which meets the OECD301B standard, and its ecotoxicity EC50 value is greater than 100mg/L, which is actually non-toxic. When incinerated, its calorific value (35MJ/kg) is equivalent to that of polypropylene, and no harmful substances such as dioxins are produced. Carbon footprint analysis shows that the CO2 equivalent emissions of each ton of Erucamide production process are 1.8 tons lower than those of petroleum-based lubricants. In the context of increasingly stringent environmental regulations, this advantage will become increasingly important.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Erucamide

Erucamide Manufacturer

Contact Us

As an experienced Erucamide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Erucamide CAS 112-84-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.