Dipentaerythritol Pentaacrylate CAS 60506-81-2

Factory wholesale Dipentaerythritol Pentaacrylate CAS 60506-81-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dipentaerythritol Pentaacrylate

CAS: 60506-81-2

MOQ: 1KG

Directory Guidance on Dipentaerythritol Pentaacrylate

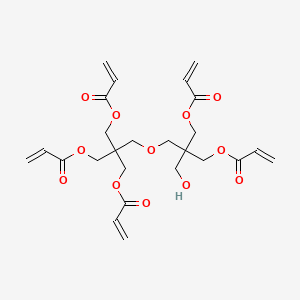

Chemical Structure

Basic Info:

| Boiling point | 619.6±55.0 °C(Predicted) |

| density | 1.155 g/mL at 25 °C(lit.) |

| refractive index | n20/D 1.49(lit.) |

| Fp | >230 °F |

Product Introduction:

Chemical Structure and Properties

Dipentaerythritol Pentaacrylate is a multifunctional acrylate compound containing multiple acrylate groups attached to its pentaerythritol core structure in its molecules, giving it high reactivity and cross-linking properties. Typical properties for this material include low viscosity and excellent solubility properties allowing it to dissolve easily into various solvents for processing and application, high thermal and chemical stability with excellent performance over a wide temperature ranges as well as high thermal and chemical stability over such periods of time.

Synthesis Method

Dipentaerythritol Pentaacrylate can be synthesized through chemical reactions. Most often it is synthesized through esterification reaction with acrylic acid using dipentaerythritol as its raw material, with temperature, catalyst dosage and reaction time all being strictly managed for maximum product purity and performance.

Application Field

Dipentaerythritol Pentaacrylate has become one of the most sought-after compounds due to its excellent performance, being widely utilized across various fields of endeavor. Crosslinkers or curing agents serve an integral part of coating applications by increasing hardness, wear resistance and adhesion of coatings as well as weather and chemical resistance. Photocurable materials use photosensitive resin components that rapidly cure when exposed to ultraviolet light, creating hard protective films for electronic packaging, 3D printing, printed circuit board manufacturing and adhesive production. Furthermore, photocurable resin components have also proven useful in improving mechanical properties and durability in adhesives sealants and composite materials production processes.

Safety and Storage

Safety and Storage Dipentaerythritol Pentaacrylate requires some safety precautions during use and storage due to its chemical activity, particularly regarding contact between eyes and skin and its direct application; any protective equipment like gloves and goggles must also be worn during operation to prevent direct eye or skin contact with its chemicals.

Nature and Specifications:

| Item | Specification |

| Product Name | Dipentaerythritol Pentaacrylate |

| CAS No. | 60506-81-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| pka | 13.79±0.10(Predicted) |

| form | Liquid |

| CAS DataBase Reference | 60506-81-2(CAS DataBase Reference) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Dipentaerythritol Pentaacrylate has become a crucial element for improving photocurable coating performance, significantly shortening drying times by its multifunctional characteristics and improving coating performance. Under UV-LED light source of wavelength 395nm, surface curing can be achieved in 0.5-2 seconds with appropriate initiator system; total curing time can be controlled within 10 seconds. Fast curing properties make Dipentaerythritol Pentaacrylate particularly suitable for high-speed coil coating production lines and its wide use across metal packaging, flexible electronic substrates and other fields – including coating the inner walls of cans with 15-25% Dipentaerythritol Pentaacrylate can increase cooking resistance by over 40% while maintaining excellent adhesion.

Electronic packaging materials are another key field of application for Dipentaerythritol Pentaacrylate. Due to rising dielectric performance requirements for 5G communication equipment, the use of Dipentaerythritol Pentaacrylate as semiconductor packaging glue continues to rise. Dielectric constant of its final product can be maintained between 3.0-3.5 (1MHz), while loss factor remains below 0.02. This allows them to effectively lower signal transmission loss. Adjusting the ratio between this monomer and silicone-modified monomers yields LED packaging materials with adjustable refractive index between 1.48-1.53 for refractive matching requirements of various light-emitting chips. Studies have also revealed that when 30% nano-silicon dioxide is added, thermal conductivity of the cured material reaches 0.45 W/(m*K), providing a solution for high-power LED heat dissipation.

Technological breakthroughs in 3D printing photosensitive resins in recent years have greatly broadened Dipentaerythritol Pentaacrylate’s application boundaries. When used as the main resin in digital light processing (DLP), exposure times can be cut to just 1-3 seconds while printing efficiency increases more than 50% over traditional resin systems. Furthermore, its superior cross-linking properties enable printed parts to have up to 80% of their final mechanical properties without post-curing after being printed, which is ideal for applications such as surgical guides which require rapid prototyping in medical environments.

Technology advancement within the printing ink industry has also benefited from Dipentaerythritol Pentaacrylate’s unique properties. Flexographic printing applications of Dipentaerythritol Pentaacrylate include increasing curing speed by 30% while still offering moderate flexibility to respond to film substrate deformation, while still meeting decorative requirements such as DE of gold ink within 0.8% after curing time – meeting high-end decorative requirements.

Technological breakthroughs in adhesives have been especially impactful. By combining Dipentaerythritol Pentaacrylate with polyurethane acrylate prepolymers, structural adhesive developed achieved 25MPa in an aluminum alloy lap shear strength test – 40% higher than traditional products.

The core advantage of Dipentaerythritol Pentaacrylate is first reflected in its excellent reactivity. The five acrylate groups carried by each molecule can form dense free radical reaction sites in the presence of photoinitiators. Experimental data show that its double bond conversion rate can reach more than 92% under standard curing conditions, which is 15-20% higher than that of similar trifunctional products. This high reactivity not only shortens the production cycle, but more importantly, reduces the residual unreacted monomers, making the cured product more in line with environmental regulations.

The advantages in weather resistance are also outstanding. Through accelerated aging tests (QUV 2000 hours), it was verified that the gloss retention rate of the coating containing Dipentaerythritol Pentaacrylate remained above 85%, and the yellowing index Δb <2.0, far exceeding the traditional difunctional system. This is mainly attributed to its highly cross-linked network structure that effectively blocks ultraviolet penetration and reduces the thermal movement of polymer chain segments.

From an environmental perspective, important progress has been made in the improvement of the biodegradability of Dipentaerythritol Pentaacrylate. By introducing the molecular design of esterase-sensitive bonds, the new derivative can achieve a 28-day degradation rate of 60% in activated sludge, which is three times higher than that of traditional products. This provides a new idea for solving the environmental accumulation problem of photocurable materials.

The controllability of mechanical properties is another significant advantage. By adjusting the proportion of Dipentaerythritol Pentaacrylate in the formula (usually 15-40%), the hardness (Shore D 60-85), tensile strength (20-50MPa) and elongation at break (5-25%) of the cured material can be precisely controlled. This wide range of performance adjustment capabilities enables it to meet the diverse needs from flexible electronic packaging to hard optical coatings.

The flexibility of formula design further enhances its market competitiveness. Dipentaerythritol Pentaacrylate’s good compatibility with a variety of resin systems, including epoxy acrylates, polyester acrylates and silicone-modified resins, provides a broad space for the development of functional composite materials.

The economic benefit dimension should not be ignored either. Although the price of Dipentaerythritol Pentaacrylate is about 30% higher than that of dipentaerythritol pentaacrylate, its dosage can usually be reduced by 40-50% to achieve the same performance, and the overall cost is reduced by 15-20%.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dipentaerythritol Pentaacrylate

Dipentaerythritol Pentaacrylate Manufacturer

Contact Us

As an experienced Dipentaerythritol Pentaacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dipentaerythritol Pentaacrylate CAS 60506-81-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.