Dimethyl Azelate CAS 1732-10-1

Factory wholesale Dimethyl Azelate CAS 1732-10-1

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dimethyl Azelate

CAS: 1732-10-1

MOQ: 1KG

Directory Guidance on Dimethyl Azelate

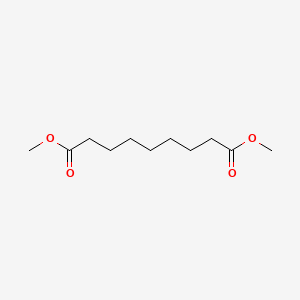

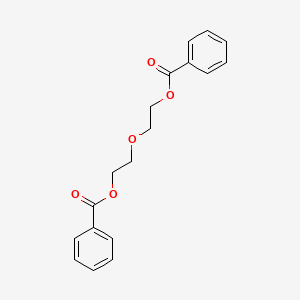

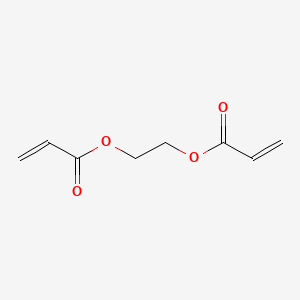

Chemical Structure

Basic Info:

| Melting Point | 18 °C |

| Boiling Point | 156 °C/20 mmHg (lit.) |

| Density | 1.007 g/mL at 25 °C (lit.) |

| Vapor Pressure | <1 mm Hg ( 20 °C) |

| Refractive Index | n20/D 1.435(lit.) |

Dimethyl Azelate Introduction:

Dimethyl Azelate (DMA) is an organic compound with the chemical formula C11H20O4. At room temperature it appears colorless and transparent and exudes an esters aroma. Molecular structure of Azelaic Acid Methanol Esters. Molecular chain contains one long carbon chain with two methoxy groups. This unique structure provides it with superior solubility and chemical stability, making it compatible with an array of organic solvents (including ethanol and acetone) as well as some polar polymers materials. Physical properties: Dimethyl Azelate has an approximate boiling point of 285degC and flash point higher than 120deg C, providing high thermal stability while still being fluid in low temperature environments.

Dimethyl Azelate production in industry typically utilizes ester exchange or direct esterification processes. The direct esterification method employs azelaic acid and methanol as raw materials and conducts dehydration reactions using acidic catalysts such as concentrated sulfuric acid or solid acid catalysts. Recent years, as green chemistry becomes a more mainstream concept, many enterprises have begun using ionic liquid or molecular sieve catalysts to increase reaction efficiency and product purity. As part of the production process, selecting raw material ratios, reaction temperatures, and catalytic systems directly affects the final product’s quality indicators – specifically acid value, color intensity and moisture content must all be strictly managed within industry standards.

Dimethyl Azelate, as a multifunctional fine chemical, plays an essential role in various industries. Its long-chain alkyl structure can effectively lower surface tension of materials while its ester groups enhance affinity with polar substances; these two features enable its use both as plasticizer for polymers and precursor for surfactants. When stored and transported safely, Dimethyl Azelate should be stored away from strong oxidants in cool and ventilated storage facilities to preserve long-term chemical properties stability.

From an economic development viewpoint, global Dimethyl Azelate production capacity is predominantly distributed in three areas – Asia-Pacific, Europe and North America – with China serving as both producer and consumer; Chinese authorities have actively promoted capacity upgrading over recent years. With increasing environmental protection regulations and technological progress in downstream industries, demand for high purity (>=99.5%) and low volatility products has increased significantly. Innovations have also been made in the research and development of bio-based Dimethyl Azelate. Many enterprises have implemented sustainable production processes utilizing vegetable oil derivatives as raw materials, opening up opportunities for further green development of industry.

Nature and Specifications:

| Item | Specification |

| Product Name | Dimethyl Azelate |

| CAS No. | 1732-10-1 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | >230 °F |

| Storage Temp. | Sealed in dry,Room Temperature |

| Solubility | Chloroform (Slightly), Ethyl Acetate (Slightly) |

| Form | Liquid |

| Specific Gravity | 1.007 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Dimethyl Azelate

The coating and ink industry is another important application area of Dimethyl Azelate. As a high-boiling point solvent for solvent-based coatings, its slow evaporation rate helps to improve the leveling of the coating film and reduce orange peel and pinhole defects. In ultraviolet light-curing (UV) ink systems, this compound can participate in photopolymerization reactions as an active diluent, which can not only adjust the viscosity of the system, but also enhance the wear resistance of the cured film layer. What is more noteworthy is that Dimethyl Azelate has an outstanding wetting and dispersing effect on pigments. Its application in high-end metallic glitter paint can improve the directional arrangement of metal powders and enhance the mirror reflection characteristics of the coating.

In the fields of personal care and medicine, derivatives of Dimethyl Azelate are gradually expanding their application boundaries. The monomethyl ester derivatives obtained by transesterification have an amphiphilic structure and can be used as an emulsifier in the preparation of skin care lotions. In drug synthesis, the methoxy group of this substance can be used as a protective group to participate in multi-step organic synthesis reactions, especially in the preparation of intermediates of antibiotics and anti-tumor drugs. In addition, its low toxicity and biodegradability characteristics meet the safety standards of pharmaceutical excipients, and its application research in sustained-release preparations and transdermal drug delivery systems has entered the pilot stage.

Dimethyl Azelate is widely utilized within the textile industry as an antistatic additive for synthetic fibers such as polyester. When added during spinning processes, Dimethyl Azelate helps reduce melt viscosity while improving spinning stability, giving long-lasting antistatic properties to polyester yarns. Fabric finishing process uses softeners as an important component to increase softness of cotton and linen fabrics, without altering moisture absorption and breathability. Furthermore, some research institutes are exploring their use in developing intelligent temperature-controlled fibers which realize dynamic temperature regulation functions via phase change energy storage mechanisms.

The demand for Dimethyl Azelate in the field of environmentally friendly materials is growing rapidly. In the research and development of biodegradable plastics, this substance, as a copolymer of polylactic acid (PLA), can effectively improve the impact strength and heat deformation temperature of the material. In the lithium-ion battery electrolyte system, its high dielectric constant and wide electrochemical window characteristics are used to develop new flame retardant additives, which help to improve the safety performance of the battery. In addition, in the field of water-based industrial paints, Dimethyl Azelate can replace traditional volatile organic compounds (VOCs) as a film-forming aid, promoting the transformation of the coatings industry towards an environmentally friendly direction.

From the perspective of the global market structure, the application of Dimethyl Azelate is extending to high value-added fields. In terms of electronic chemicals, its ultra-pure products (metal ion content ≤1ppm) have been used in the preparation of semiconductor packaging materials; in the aerospace field, special grade products have become the core components of high-temperature resistant composite materials. These emerging applications not only expand the market space of products, but also promote the continuous innovation of production technology. For example, the application of molecular distillation technology and supercritical fluid extraction technology makes it possible for product purity to break through the technical bottleneck of 99.9%.

The Advantages Of Dimethyl Azelate

From a chemical perspective, Dimethyl Azelate stands out in its designability and stability of molecular structure. When compared with short-chain ester compounds, its long carbon chain structure can effectively decrease crystallization tendency while providing liquid stability over a wide temperature range.

The electronic effect of the ester group makes Dimethyl Azelate naturally resistant to ultraviolet radiation, which is particularly important in outdoor plastic products and weather-resistant coatings. More importantly, the hydrolysis rate of this substance in strong acid and alkali environments is significantly lower than that of similar products. This chemical inertness enables it to maintain functional stability under special working conditions.

Application compatibility is the key advantage of this product in expanding the market. In the field of plastic processing, Dimethyl Azelate has good synergistic effects with various stabilizers and lubricants, and will not cause precipitation or migration problems. In the compound system, Dimethyl Azelate can form a synergistic combination with other functional additives (such as flame retardants and antioxidants). This compatibility provides a technical basis for the development of multifunctional composite materials.

The economic advantage of Dimethyl Azelate is reflected in the cost control system of the entire industry chain. In terms of raw materials, azelaic acid can be obtained through renewable methods such as castor oil hydrolysis. The stable supply of this biomass raw material avoids the impact of oil price fluctuations.

In the production process, the application of continuous reaction devices has increased the single-line production capacity to 10,000 tons, and the unit energy consumption has been reduced by 18%. From the perspective of use cost, the addition amount can be reduced by 15% compared with traditional plasticizers to achieve the same performance indicators. This high efficiency can produce significant economic benefits in large-scale production. More importantly, the compatibility of Dimethyl Azelate with existing production equipment avoids additional investment in production line transformation.

In terms of environmental friendliness, Dimethyl Azelate shows dual advantages that are in line with the development of modern industry. Its biodegradability has been tested by OECD 301B standards, and the degradation rate in 28 days exceeds 60%, which is much higher than that of traditional plasticizers. The emission of volatile organic compounds (VOC) is reduced by more than 40% compared with phthalates, which has significant environmental value in the manufacture of automotive interior materials and children’s toys. Life cycle assessment (LCA) studies have shown that the carbon footprint of Dimethyl Azelate produced using bio-based raw materials is 32% lower than that of petroleum-based products, which provides strong support for downstream companies to achieve carbon neutrality goals.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dimethyl Azelate

Dimethyl Azelate Manufacturer

Contact Us

As an experienced Dimethyl Azelate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dimethyl Azelate CAS 1732-10-1 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.