Diisononyl Phthalate CAS 68515-48-0

Factory wholesale Diisononyl Phthalate CAS 68515-48-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diisononyl Phthalate

CAS: 68515-48-0

MOQ: 1KG

Directory Guidance on Diisononyl Phthalate

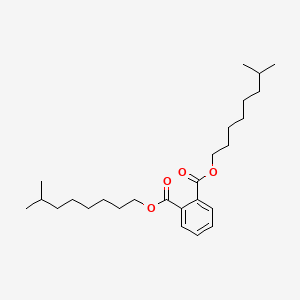

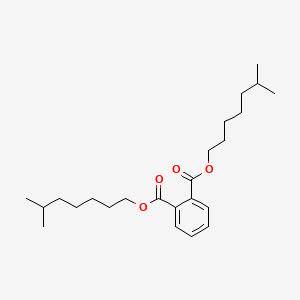

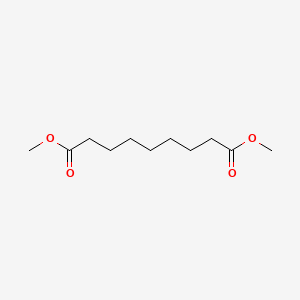

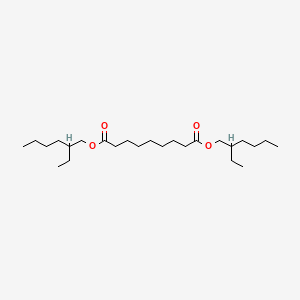

Chemical Structure

Basic Info:

| Boiling Point | 279-287 °C |

| Density | 0.972 g/mL at 25 °C(lit.) |

| Pour Point | -54 |

| Vapor Pressure | 1 mm Hg ( 200 °C) |

| Refractive Index | n20/D 1.485(lit.) |

Diisononyl Phthalate Introduction:

Diisononyl Phthalate (DINP for short) is an important phthalate compound and representative product from the high molecular weight phthalate family. Its chemical structure results from esterification between phthalic acid and isononanol with a molecular weight of about 420 g/mol and takes the form of a transparent oily liquid at room temperature.

As a high-performance plasticizer, Diisononyl Phthalate plays an irreplaceable role in industrial production. The longer alkyl structure in its molecular chain endows it with unique physicochemical properties, such as high thermal stability, low volatility, and excellent plasticizing efficiency. These characteristics make it an important choice to replace traditional low molecular weight phthalates, especially in the context of increasingly strict environmental regulations, and the market demand for Diisononyl Phthalate continues to grow.

Chemically speaking, Diisononyl Phthalate production largely relies on ester exchange reactions catalyzed by acid. Industrially, phthalic anhydride and isononanol are typically combined under high temperature conditions to achieve high conversion rates by controlling both temperature and pressure in stages. Accurate control over raw material purity, catalyst type and reaction time must also be adhered to during production so as to guarantee the final product adheres to standards in terms of molecular weight distribution.

Modern production processes typically utilize continuous production devices, while unreacted raw materials are recycled through distillation towers, increasing production efficiency while significantly decreasing energy consumption and emissions. Furthermore, with the increased awareness of green chemistry practices some companies are beginning to implement solid acid catalysts as an alternative solution to reduce acidic wastewater burden.

Diisononyl Phthalate’s physical properties typically range from 70-100 milliPa*s (25), density is 0.97 to 0.98 g/cm3, and boiling point exceeds 380. These parameters directly impact its processing performance and application scenarios, particularly considering that traditional plasticizers such as dioctyl phthalate (DOP) have migration rates that significantly exceed Diisononyl Phthalate’s. Furthermore, its molecular structure contains isononyl side chains which reduce migration rates significantly for long-term stability of products.

Diisononyl Phthalate boasts a flash point greater than 200, eliminating any likelihood of combustion during high temperature processing and providing superior safety performance. Furthermore, its compatibility with polyvinyl chloride (PVC) has been tested over many years and added at 40%-60% concentration levels without leakage issues or leakage issues occurring.

Nature and Specifications:

| Item | Specification |

| Product Name | Diisononyl Phthalate |

| CAS No. | 68515-48-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | >230 °F |

| Storage Temp. | Refrigerator |

| Solubility | Chloroform, Methanol |

| Form | Oil |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Diisononyl Phthalate

In the field of plastic processing, the main application scenarios of Diisononyl Phthalate are concentrated in the production of soft PVC products. By closely cooperating with PVC resin, it can effectively reduce the glass transition temperature and give the material excellent flexibility and resilience. This characteristic makes it widely used in products with high mechanical properties requirements such as wire and cable sheaths, automotive interior parts, and building sealing strips.

Especially in the automotive industry, PVC materials plasticized by Diisononyl Phthalate can not only meet the operating temperature range of -40℃ to 120℃, but its aging resistance can also ensure that the parts maintain color stability under long-term ultraviolet radiation. With the growing demand for lightweight materials in new energy vehicles, its application ratio in low-density polymer composites is on the rise.

The demand for Diisononyl Phthalate in the coatings and ink industry cannot be ignored. As an auxiliary plasticizer, it can improve the flexibility of film-forming substances such as acrylic resin and polyurethane, while reducing system viscosity to enhance construction performance. Adding an appropriate amount of this product to the printing ink formula can enhance the adhesion and wear resistance of the ink layer, especially when printing on packaging materials that require repeated bending.

The application history of Diisononyl Phthalate in nitrocellulose coatings has exceeded thirty years, and its good compatibility with nitrocellulose has maintained a stable market share in fields such as wood coatings and leather finishing agents. It should be pointed out that with the breakthrough of water-based coating technology, although its application in solvent based systems is facing challenges, its new application path in environmentally friendly coatings is being explored through the innovation of microemulsion technology.

The usage of Diisononyl Phthalate in the field of daily chemical products is relatively small, but the technical requirements are higher. In the formulas of personal care products such as nail polish and hair spray, it is mainly used as a film-forming aid. Its low volatility property helps to extend the product’s retention time on the skin surface. The cosmetics industry has strict requirements for its purity, usually needing to reach a chromatography-level standard of over 99.5%, and strictly control the residue of heavy metals.

In the medical field, Diisononyl Phthalate has specific applications in the manufacturing of disposable infusion tubes, blood bags, and other medical devices. Its combination with PVC ensures the stability of the material during gamma ray sterilization. Although there is competition for alternative materials, its comprehensive advantages in cost and performance still make it occupy an important position.

In the field of environmentally friendly material development, the research on biobased modification of Diisononyl Phthalate has become a hot topic in recent years. By replacing some of the isononyl alcohol raw materials with branched alcohols prepared by biological fermentation, researchers have successfully developed Diisononyl Phthalate derivatives with a biological content of up to 30%. This type of product not only retains traditional plasticizing properties, but also reduces its carbon footprint by 15% -20%, providing a new raw material choice for green certified products.

The feasibility study of Diisononyl Phthalate in biodegradable plastic systems has made progress, and experiments have shown that its blend with polylactic acid (PLA) maintains a certain degree of flexibility while maintaining better controllability of the degradation cycle than pure PLA materials. These innovative applications have opened up a broader market space for it.

The demand for Diisononyl Phthalate in the electronics and electrical industry is mainly reflected in the manufacturing of insulation materials. In the insulation layer formula of wires and cables, its synergistic effect with PVC can endow the material with stable dielectric properties, with a volume resistivity of over 1 × 10 ^ 14 Ω· cm, fully meeting the insulation requirements of high-voltage cables. Especially in the field of high-frequency cables for 5G communication equipment, its low dielectric loss characteristics make it stand out among many plasticizers.

The Advantages Of Diisononyl Phthalate

The performance advantage of the product is first reflected in its outstanding thermal stability system. The benzene ring structure in the Diisononyl Phthalate molecule forms a steric hindrance effect with large-volume branched-chain alkyl groups, significantly delaying the oxidative degradation process. This characteristic is directly translated into processing advantages. During the mixing or extrusion molding process in the internal mixer, the PVC system plasticized by Diisononyl Phthalate can withstand a higher shear rate without thermal decomposition, which is of great significance for improving production efficiency.

Low volatility is the core competitiveness that distinguishes Diisononyl Phthalate from low-molecular-weight plasticizers. This characteristic is particularly important in fields such as automotive interior parts and medical equipment where the control of volatile organic compounds (VOCs) is strict. Long-term aging tests have confirmed that after 3,000 hours of accelerated aging in 85 ° C hot air, the weight loss rate of Diisononyl Phthalate plasticized products is controlled within 2%, and the hardness change does not exceed 5 Shore A.

The comprehensive optimization of processing performance is the technical guarantee for Diisononyl Phthalate to continuously occupy the market. Rheological tests show that the equilibrium torque of its plasticizing system is 10%-15% lower than that of similar products, which means lower energy consumption and shorter mixing cycle. During the extrusion molding process, the outlet expansion rate of its formula melt is relatively small, which is conducive to precisely controlling the dimensional tolerance of the product.

Especially in high-filling formulations, the lubricating effect of Diisononyl Phthalate can effectively improve the conveying efficiency of materials in the screw and prevent the occurrence of bridging phenomena. The accumulation of these processing advantages enables it to always remain competitive in the modern manufacturing industry that pursues lean production.

Environmental protection and safety constitute the market access advantages of Diisononyl Phthalate. According to the results of the OECD 407 subchronic toxicity test, its level of unobserved adverse effects (NOAEL) was 152 mg/kg bw/day, significantly higher than that of most traditional plasticizers.

Ecotoxicological studies have shown that the bioaccumulation coefficient (BCF) of Diisononyl Phthalate in water bodies is less than 100, and it belongs to substances that are difficult to bioaccumulate. These scientific data support its passing of the comprehensive assessment of the EU REACH regulation. For manufacturing enterprises, it has greatly simplified the supply chain management process.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Diisononyl Phthalate

Diisononyl Phthalate Manufacturer

Contact Us

As an experienced Diisononyl Phthalate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diisononyl Phthalate CAS 68515-48-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.