Diglycerol CAS 627-82-7

Factory wholesale Diglycerol CAS 627-82-7 With Free Sample

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diglycerol

CAS: 627-82-7

MOQ: 1KG

Directory Guidance on Diglycerol

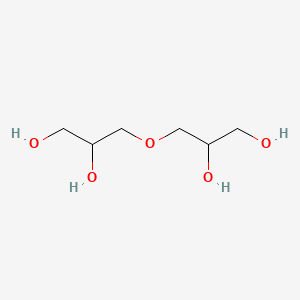

Chemical Structure

Basic Info:

| Melting point | 319 °C |

| Boiling point | 214.38°C (rough estimate) |

| density | 1.280 g/mL at 20 °C(lit.) |

| refractive index | n20/D 1.489 |

| Fp | 240°C |

Product Introduction:

Diglycerol (CAS: 627-82-7), known as 3,3′ -oxy dipropane-1, 2-diol, is a polyhydroxyl compound formed by two glycerols (glycerol) linked by ether bonds with the formula C6H14O5 and molecular weight 166.17. Its structure contains four hydroxyl groups, which give it unique chemical activity and physical properties. In appearance, Diglycerol is typically colorless to yellowish viscous liquid with a density of about 1.280 g/mL (20 ° C), a boiling point ranging from 214.38 ° C (estimated) to 270 ° C (2.0kPa condition), and a refractive index of about 1.489. Its melting point is 319 ° C, but it exists more in liquid form in practical applications. The substance is soluble in water, methanol and ethanol, slightly soluble in chloroform and DMSO, insoluble in ether, and has strong hygroscopic property.

From the perspective of chemical properties, the hydroxyl structure of diglycerol enables it to undergo multiple reactions such as esterification and etherification, while the presence of its ether bond enhances the molecular stability. In addition, its flash point is as high as 240 ° C, good stability, but decomposition may occur in the strong oxidizing environment. In industrial preparation, Diglycerol is synthesized mainly by glycerol dimerization, condensation of allyl alcohol with acetone, or ring-opening reaction of epiclorohydrin with sodium hydroxide, of which glycerol dimerization is dominant due to its maturity and environmental friendliness.

The development of Diglycerol began in the mid-20th century, when it was discovered early on by chance as a byproduct of the glycerol production process. With the deepening of research on polyhydroxyl compounds, their application potential is gradually explored. Japan took the lead in introducing it to the field of cosmetics in the 1980s, and then the European and American markets also accelerated the exploration of its performance. In recent years, with the rise of bio-based materials, Diglycerol has attracted attention because it can be derived from natural glycerol. For example, 100% bio-based diols developed by Cargill, such as Pripol 2033 and 2043, have been successfully applied to polymer materials such as polyurethanes, demonstrating their value in green chemistry.

According to industry standards and safety norms, Diglycerol is classified as a common chemical, with attention to its flammability and mild irritation of the skin and eye. The International Chemical Safety Card (EINECS) number is 211-013-8 and the customs code is 2905.49.5001. In storage and transportation, it is recommended to avoid light, cool and sealed storage, avoid contact with strong oxidants.

Nature and Specifications:

| Item | Specification |

| Product Name | Diglycerol |

| CAS No. | 627-82-7 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Room Temperature |

| solubility | Chloroform, DMSO, Methanol (Slightly), Water (Soluble) |

| pka | 13.31±0.20(Predicted) |

| form | Oil |

| color | Colourless to Light Yellow |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Diglycerol has a wide range of applications, mainly covering daily chemicals, medicine, food and industrial materials. In the daily chemical industry, its core value is reflected in its moisturizing properties. Compared with traditional glycerol, diglycerol has a larger molecular weight and a more dispersed hydroxyl distribution, so it can reduce excessive absorption of skin moisture and provide a milder and longer-lasting moisturizing effect. This feature makes it a key ingredient in high-end skin care, hair conditioner and facial cleanser, especially in the Japanese and European markets, where its addition ratio has become one of the indicators of product quality. In addition, it can also adjust the viscosity of soap-based products, reduce the tightness after washing, and enhance the fineness of the foam, so it is widely used in shower gel and facial soap.

In the field of industrial materials, derivatives of Diglycerol show remarkable functionality. For example, diglycerin oleate as a defoamer and lubricant rust inhibitor can effectively improve the operation efficiency of mechanical equipment; Diglycerin stearate is used as an antifogging agent for polyvinyl chloride packaging materials to extend the shelf life of the product. In recent years, its application in the field of new energy is particularly prominent. In the case of power battery assembly, the addition of Diglycerol to two-component polyurethane adhesives significantly enhances the flexibility and aging resistance of the colloid to lycerol, which ADAPTS the battery to complex environments such as high temperature and vibration.

The demand for Diglycerol in the pharmaceutical industry is concentrated in the excipients and intermediates. Its high-purity products (such as 98% HPLC grade) can be used as carriers for drug sustained-release agents or for the synthesis of bioactive ester compounds. For example, diglycerin tetramethacrylate is an important monomer in medical adhesives, while diglycerin ricinoleate is used in the preparation of slow-release drug capsules. In addition, its solubilization effect in in vitro diagnostic reagents has been gradually verified.

In the food industry, fatty acid ester derivatives of Diglycerol (such as diglyceryl stearate and laurate) are recognized as safe emulsifiers and are widely used in margarine, butter, and bakery products.

From the perspective of global market distribution, Asia-Pacific occupies the dominant position of Diglycerol consumption, which is closely related to its developed daily chemical and electronic industries. The European and American markets pay more attention to its application innovation in bio-based materials and polymer synthesis. It is predicted that by 2030, the global market size will achieve double-digit growth of Diglycerol driven by industries such as new energy vehicles and green packaging.

Diglycerol’s core competitiveness stems from its unique combination of chemical structure and properties. First, the four hydroxyl and ether bond structures in the molecule give excellent reactivity and stability. For example, in the esterification reaction, the high density distribution of hydroxyl group enables it to combine efficiently with various fatty acids to form surfactants with different properties. The existence of ether bond significantly improves the hydrolysis resistance of the product, so that it can maintain its function in wet or high temperature environment. Diglycerol has a larger molecular weight and higher viscosity than conventional glycerol, and thus provides better film formation and adhesion in adhesives and coatings.

From a safety perspective, the biocompatibility of Diglycerol is prominent. The raw glycerin can be obtained by hydrolysis of vegetable oils and fats, which meets the requirements of EU REACH regulation and FDA for food contact materials. Experimental data showed that its median lethal dose (LD50) was greater than 5000 mg/kg (rat oral), belonging to the actual non-toxic level, and no sensitization and genotoxicity reports, suitable for infant care products. In addition, the production process can achieve low energy consumption and low emissions by optimizing the catalyst and reaction conditions, which is in line with the development trend of green chemistry.

In application performance, the weather tolerance and compatibility of Diglycerol are advantageous. In the case of polyurethane materials, the addition of 5-25% Diglycerol reduces the glass transition temperature (Tg) of the material while improving impact and hydrolysis resistance, which is critical for applications in harsh environments such as automotive battery packaging. In the daily chemical formula, its synergistic effect with silicone oil, hyaluronic acid and other ingredients can achieve multiple effects of “moisturizing, softening-repairing”, and it is not easy to separate from other polar ingredients.

In terms of cost-effectiveness, the industrial production of Diglycerol has achieved economies of scale. In addition, the diversity of its derivatives reduces customers’ demand for multiple additives, thereby reducing overall formulation costs. For example, a single glycerol stearate can replace the traditional combination of emulsifiers and preservatives.

Contact Us

Product Package picture:

Related References:

chemicalbook-Diglycerol

Diglycerol Manufacturer

Contact Us

As an experienced Diglycerol manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diglycerol CAS 627-82-7 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.