Diethyleneglycol Diacetate CAS 628-68-2

Factory wholesale Diethyleneglycol Diacetate CAS 628-68-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diethyleneglycol Diacetate

CAS: 628-68-2

MOQ: 1KG

Directory Guidance on Diethyleneglycol Diacetate

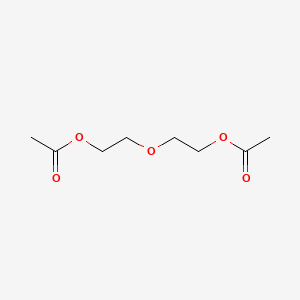

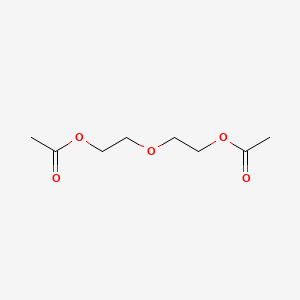

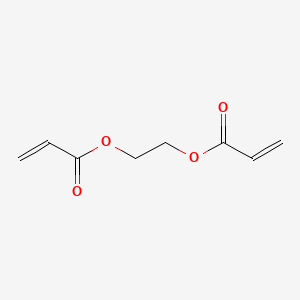

Chemical Structure

Basic Info:

| Melting Point | 19°C |

| Boiling Point | 200°C (estimate) |

| Density | 1.101 g/mL at 25 °C |

| Refractive Index | n20/D 1.431 |

Diethyleneglycol Diacetate Introduction:

Diethyleneglycol Diacetate, chemical formula C8H14O5, molecular weight 206.2. It is a nearly colorless clear liquid with a faint fruity smell. From the physical properties, its boiling point is about 250-255 degrees Celsius, and the relative density is between 1.08-1.09. In terms of solubility, it can be miscible with most organic solvents such as ethanol and ether in any proportion, but its solubility with water is poor. This solubility property makes it have specific application scenarios in the field of organic synthesis.

There are two main methods for synthesizing Diethyleneglycol Diacetate. One is to esterify diethylene glycol with acetic acid under the action of an acidic catalyst. During the reaction, parameters such as temperature, pressure and reaction time need to be controlled to ensure the full progress of the esterification reaction and improve the purity and yield of the product.

Another method is to use ethylene oxide and acetic acid for a stepwise addition reaction. Under a suitable catalyst system, ethylene oxide is ring-opened and reacts with acetic acid to generate an intermediate product, which is then further reacted to obtain diethyleneglycol diacetate. These two synthesis methods have their own advantages and disadvantages. The former has easy-to-obtain raw materials but the reaction may be accompanied by more side reactions, while the latter has relatively mild reaction conditions but has high requirements for catalysts.

From the perspective of chemical reactivity, the ester groups in Diethylene glycol Dicetate molecules endow them with certain chemical activity. It can undergo hydrolysis reaction, and under acidic or alkaline conditions, the ester group will gradually break to form the corresponding alcohol and acid. When in contact with some active metals such as sodium and potassium, it can also react to generate hydrogen and corresponding metal organic compounds. In addition, it can also participate in condensation reactions, ester exchange reactions, etc. under specific conditions. These reaction characteristics provide a basis for its application in fine chemicals, polymer synthesis and other fields.

Nature and Specifications:

| Item | Specification |

| Product Name | Diethyleneglycol Diacetate |

| CAS No. | 628-68-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | >230 °F |

| Form | Powder to Lump to Clear Liquid |

| Color | White or Colorless to Almost white or Almost colorless |

| LogP | 0.13 at 25℃ |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Diethyleneglycol Diacetate

Diethylene glycol diacetate is widely utilized throughout industry for its versatility as an excellent solvent and plasticizer, particularly within the plastics industry. DEGG’s primary role lies as a high-performance solvent/plasticizer combination used on PVC, polyester and polyurethane resins compared with traditional phthalate plasticizers – not only does it increase flexibility and low temperature impact resistance, but it also significantly decreases volatilization losses during processing, helping lower production costs significantly.

Diethylene Glycol Dicetate can significantly enhance the weather resistance and anti-ageing performance of PVC cable sheath and film produced with DEDG added. Furthermore, Diethylene glycol Dicetate’s excellent compatibility with resins means less material surface precipitation due to plasticizer migration – making its application in highly transparent plastic products all the more desirable.

Diethylene Glycol Dicetate, more commonly known by its acronym DEDG, plays an integral part in coatings and inks applications as a film-forming aid and solvent. With its high boiling point and low volatilization rate, DEDG helps extend opening times of coatings, achieve uniform drying rates, reduce orange peel effects such as shrinkage and orange peel effects, as well as help eliminate surface defects such as orange peel. Furthermore, DEDG boasts strong dispersibility for pigments and fillers enhancing coloring power as well as printing adaptability of ink.

Diethylene glycol Diacetate can be incorporated into environmentally-friendly water-based coatings as a co solvent to lower surface tension, enhance flowability and adhesion, as well as meet performance criteria of different scenarios. Furthermore, its use as UV curable coatings has steadily expanded as its curing speed and film hardness can be tailored accordingly to meet performance criteria.

Diethylene Glycol Dicetate can also find applications within the adhesives industry. When used as an active diluent for solvent based adhesives, DEGG can effectively lower viscosity levels while simultaneously improving construction convenience without impacting final bond strength significantly.

Diethylene Glycol Diacetate’s plasticizing effect makes Diethylene glycol Diacetate suitable for pressure-sensitive adhesives and hot melt adhesives, adjusting initial and sustained viscosities of colloid mixtures according to bonding needs of different substrates. DEDG applications have also increased rapidly within electronic adhesives – for instance in improving semiconductor packaging materials’ high temperature resistance and dielectric properties.

Diethyleneglycol Dictate, with its mild skin compatibility and moisturizing properties, is used in personal care and cosmetic products for its moisturizing and moisture retention properties. Used as wetting agent it enhances moisture retention ability of products while improving skin feel during use; when used as solvent for essences or essential oils its low volatility and stability allows extended aroma retention; DEDG also serves as an auxiliary ingredient in sustained-release formulations as well as transdermal drug delivery systems.

Recently, due to the rapid expansion of both new energy and electronics industries, Diethyleneglycol Diacetate has steadily become more commonly used as lithium battery electrolytes and electronic chemicals. Lithium batteries often use Diethylene Glycol Diacetate as an electrolyte additive to enhance interface stability between electrodes and electrolyte and to prevent dendrite growth; semiconductor cleaning agents utilizing its solubility have shown success at effectively eliminating organic pollutants and metal ion residues on wafer surfaces; while research on photovoltaic materials such as encapsulation films using Diethylene glycol Diacetate for weather resistance purposes as well as increasing optical performance is progressing steadily.

The Advantages Of Diethyleneglycol Diacetate

Diethyleneglycol Diacetate excels at chemical stability. Under normal storage and usage conditions, it does not undergo chemical reactions such as decomposition and oxidation, helping maintain stable properties during long-term storage without impacting product quality or negatively affecting its integrity. Even in complex environments like organic synthesis reaction systems or coating and ink formulation systems where many different chemicals coexist together, Diethyleneglycol Diacetate remains compatible with various substances without being subject to harmful interactions that might otherwise threaten chemical stability of entire systems as a whole and product quality reliability.

From a safety perspective, Diethyleneglycol Diacetate has obvious advantages over some traditional chemicals. It has low toxicity and poses less harm to the health of operators under normal use and contact conditions. At the same time, Diethyleneglycol Diacetate is non-flammable and is not as prone to fire and other safety accidents as some organic solvents. This greatly reduces safety risks in industrial production and storage and transportation, reduces the potential losses faced by enterprises due to safety issues, and makes it more popular among many chemicals, able to meet the strict requirements of modern industry for safe production and environmental protection.

From an economic perspective, Diethyleneglycol Diacetate has a high cost-effectiveness. Its raw material sources are relatively wide, and the synthesis process has been continuously optimized, and the production cost has gradually decreased. In practical applications, Diethyleneglycol Diacetate can play a significant role with a small amount of use. For example, as a solvent in coatings, only an appropriate amount of addition can effectively improve the performance of coatings, thereby reducing production costs. At the same time, due to its advantages such as chemical stability and safety, it reduces the loss of products during storage, transportation and use, and the additional safety protection costs, further improving its economic competitiveness in the market, enabling it to stand out among many similar products, and providing many companies with a high-quality chemical option that can meet their needs in terms of performance and cost.

Diethyleneglycol Diacetate has good degradability in the natural environment and will not accumulate in the environment for a long time like some hard-to-degrade organic compounds, causing serious environmental pollution problems. Diethyleneglycol Diacetate has a relatively low content of volatile organic compounds (VOC). During its application in coatings, inks, etc., it can reduce the emission of volatile harmful substances, which helps to lower pollution to the atmospheric environment. This is in line with the increasingly strict environmental protection regulations and the concept of sustainable development. It is one of the powerful choices for industries such as coatings and inks to achieve green transformation.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Diethyleneglycol Diacetate

Diethyleneglycol Diacetate Manufacturer

Contact Us

As an experienced Diethyleneglycol Diacetate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diethyleneglycol Diacetate CAS 628-68-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.