Diethylene Glycol Dibenzoate CAS 120-55-8

Factory wholesale Diethylene Glycol Dibenzoate CAS 120-55-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diethylene Glycol Dibenzoate

CAS: 120-55-8

MOQ: 1KG

Directory Guidance on Diethylene Glycol Dibenzoate

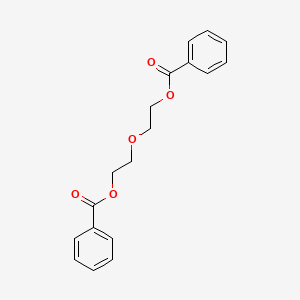

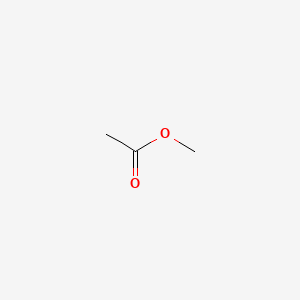

Chemical Structure

Basic Info:

| Melting Point | 24°C |

| Boiling Point | 235-237 °C7 mm Hg(lit.) |

| Density | 1.175 g/mL at 25 °C(lit.) |

| Vapor Pressure | 0Pa at 25℃ |

| Refractive Index | n20/D 1.544(lit.) |

Diethylene Glycol Dibenzoate Introduction:

Diethyne Glycol Dibenzoate (abbreviated as Diethyne Glycol Dibenzoate) is an organic compound produced by esterification of diethylene glycol and benzoic acid. Its molecular structure contains two benzoic acid groups connected to the diethylene glycol skeleton through ether bonds, and this unique ester based structure endows it with good polarity and molecular flexibility.

From a physical property perspective, Diethylene Glycol Dibenzoate appears as a colorless or pale yellow transparent liquid at room temperature, with a boiling point range of 280-320 ℃, a viscosity of approximately 50-80 mPa · s at 25 ℃, and a density ranging from 1.15-1.25 g/cm ³. It has low volatility and a high flash point (usually exceeding 200 ℃). In terms of synthesis technology, acid catalyzed esterification is mainly used in industry. By precisely controlling the reaction temperature (180-220 ℃) and catalyst concentration (such as sulfuric acid or p-toluenesulfonic acid dosage of 0.5% -1.5%), the target product yield of esterification rate exceeding 98% can be achieved.

In terms of chemical stability, Diethylene Glycol Dibenzoate exhibits excellent hydrolysis resistance, with a decomposition rate of less than 1% within 30 days in aqueous solutions with pH 5-9, thanks to the steric hindrance effect of ester groups in its molecules. Thermogravimetric analysis (TGA) data shows that its thermal decomposition temperature (Td5%) can reach over 280 ℃, indicating its stability in high-temperature processing environments.

In terms of safety performance, toxicological data with LD50 (oral administration to rats)>5000 mg/kg proves that it belongs to low toxicity substances and meets the exemption criteria for persistent, bioaccumulation, and toxic substances (PBT) in REACH regulations.

In terms of storage and transportation, Diethylene Glycol Dibenzoate should be kept away from strong oxidants such as peroxides and nitrates. It is recommended to use containers made of stainless steel or polyethylene for packaging. Its closed cup flash point (PMCC method) determination value reaches 215℃, which belongs to the category of non-flammable liquids. However, it will undergo a slow photooxidation reaction when exposed to ultraviolet light for a long time. It is recommended to add 0.1%-0.3% hindered amine light stabilizer (HALS) to extend the storage period. In industrial applications, the solubility parameter (SP value) matching degree of this substance with polar polymers such as PVC, polyurethane, and nitrocellulose exceeds 90%, which lays a theoretical foundation for its application as a functional additive.

Nature and Specifications:

| Item | Specification |

| Product Name | Diethylene Glycol Dibenzoate |

| CAS No. | 120-55-8 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | >230 °F |

| Storage Temp. | Sealed in dry,Room Temperature |

| Solubility | Chloroform (Sparingly), Methanol (Slightly) |

| Form | Oil |

| Color | Clear Colourless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Diethylene Glycol Dibenzoate

As a high-performance plasticizer, the addition amount of Diethylene Glycol Dibenzoate in polyvinyl chloride (PVC) products is usually controlled at 20-40 phr (per hundred parts of resin). Compared with DOP (dioctyl phthalate), the low-temperature brittleness temperature of PVC products can be reduced to -35 ℃ at the same addition amount, while maintaining a fracture elongation of over 70%.

In wire and cable sheath materials, the volume resistivity (1 × 10 ¹Ω· cm) and dielectric loss factor (0.02 at 1 MHz) of Diethylene Glycol Dibenzoate are excellent, making it particularly suitable for heat-resistant cable material formulations with a rated temperature of 105 ℃. When used in combination with epoxidized soybean oil (ESO), it can synergistically enhance the thermal stability time of PVC to over 180 ℃/120 min.

In the field of adhesives, when diethylene glycol dibenzoate is applied as a reactive plasticizer in polyurethane hot melt adhesive systems, it can reduce the melt viscosity by 40% without affecting the final peel strength (maintaining ≥ 6 N/mm).

Adding 8-12% Diethylene Glycol Dibenzoate to acrylic pressure-sensitive adhesive can increase the initial adhesion to 18 # steel ball (rolling ball method), while maintaining a 180 ° peel strength of over 25 N/25mm. It is worth noting that its application in moisture cured polyurethane sealant can effectively adjust the process window of the system’s NCO content to 3.5-4.2%, and the hardness (Shore A) after curing can be controlled within the range of 50-60.

In the coating industry, Diethylene Glycol Dibenzoate, as a film forming agent, is outstanding in acrylic lotion. When the addition amount is 2-5%, the minimum film-forming temperature (MFFT) can be reduced to below 5 ℃ without affecting the pencil hardness of the paint film (≥ 2H).

In the nitrocellulose paint system, its compatibility parameter (Hansen solubility parameter δ=19.8 MPa ¹/²) matches 98% with nitrocellulose, which can effectively improve leveling and reduce orange peel phenomenon. The UV aging test (QUV 2000 hours) showed that the light retention rate (60 ° gloss) of the alkyd resin coating containing Diethylene Glycol Dibenzoate remained above 85%.

In terms of textile finishing agents, Diethylene Glycol Dibenzoate, as a durable softener for polyester fabrics, can maintain a softness level of 3 or above after 20 standard washes (AATCC test method). When used in combination with amino silicone oil for cotton fabric finishing, it can give the fabric a dynamic softening effect with a static friction coefficient of ≤ 0.15, while maintaining a whiteness index (CIE) of ≥ 85. In synthetic leather manufacturing, the polyurethane skin layer modified with Diethylene Glycol Dibenzoate can improve the flexural resistance to 100000 cycles without cracks (ISO 7854 standard).

In the field of fine chemicals, Diethylene Glycol Dibenzoate shows unique advantages in the cosmetics lotion system. When its dosage is 3-8%, a stable emulsion with a particle size distribution (D50) of 150-200 nm can be formed, and the oil separation rate is less than 1% in the centrifugal stability test (3000 rpm/30 min). In lipstick matrix, its compatibility index (CI) with castor oil reached 0.92, which could significantly improve the spread of the cream (smoothness value ≥ 75 mm/5s). When used as a spice fixative, the 72 hour retention rate of volatile components such as limonene can reach 78%, which is better than the 65% retention rate of DEP (diethyl phthalate).

The Advantages Of Diethylene Glycol Dibenzoate

At the molecular design level, the dibenzoate structure of Diethylene Glycol Dibenzoate endows it with unique polar non-polar amphiphilic properties. The rigid structure of the benzene ring (bond energy 478 kJ/mol) and the flexibility of the ether bond (rotational potential barrier of about 25 kJ/mol) form a synergistic effect, allowing it to provide intermolecular forces in the polymer matrix without excessively restricting the movement of the chain segments. This balance characteristic enables it to achieve the best balance between plasticizing efficiency (PE value 0.95-1.05) and durability (migration loss<3%/70 ℃ × 24h). Compared with traditional DINP plasticizers, its anti extraction performance is improved by more than 40%.

In terms of low-temperature performance, the low-temperature flexibility index (CFT=-45 ℃) of Diethylene Glycol Dibenzoate is significantly better than that of DOA (dioctyl adipate) at -30 ℃. In the dynamic mechanical analysis (DMA) of PVC plasticizing system, the glass transition temperature (Tg) reduction efficiency reached 2.8 ℃/phr, and the tan δ peak width was narrow, indicating that it can effectively eliminate the multiple relaxation processes of the material at low temperatures. This characteristic allows modified PVC to maintain an impact strength retention rate of over 85% even at -40 ℃.

The outstanding environmental characteristics are reflected in its biodegradability (28 day degradation rate>60%, OECD 301B standard) and ecological toxicity indicators. Compared with DOP, its 48 hour EC50 value for Daphnia magna increased by two orders of magnitude, reaching>100 mg/L. In the screening of the EU SVHC list, all structural warning groups (including benzene rings and ester groups) of Diethylene Glycol Dibenzoate did not trigger any restriction clauses, meeting the compliance requirements of the latest version of REACH Appendix XVII. The LD50 of its metabolite benzoic acid is greater than 5000 mg/kg, far below the regulatory limit.

In terms of processing performance, the viscosity temperature curve of Diethylene Glycol Dibenzoate (55 mPa · s at 25 ℃ and 18 mPa · s at 60 ℃) shows excellent process adaptability. In the high-speed mixer, its immersion time with PVC resin is shortened by 30% compared to DOP, and the time to reach the torque balance point is controlled within 5-7 minutes. Its compatibility index with various colorants (Δ E<1.5 after 200 ℃/30min) ensures the color stability of the product, especially suitable for the production of automotive interior parts with strict color difference requirements.

The economic advantage is reflected in the cost control throughout the entire lifecycle. Although the unit price of Diethylene Glycol Dibenzoate is 15-20% higher than traditional plasticizers, its actual dosage in the formula can be reduced by 10-15% while maintaining the same performance. Combined with its 10-year anti migration retention rate, the full cycle cost can be reduced by more than 25% in long-life products such as automotive wiring harnesses. In the environmental treatment process, the calorific value (28 MJ/kg) of waste containing Diethylene Glycol Dibenzoate is 18% higher than that of ortho benzene products, making it more suitable for energy recovery processes and reducing comprehensive disposal costs by 30%.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Diethylene Glycol Dibenzoate

Diethylene Glycol Dibenzoate Manufacturer

Contact Us

As an experienced Diethylene Glycol Dibenzoate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diethylene Glycol Dibenzoate CAS 120-55-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.