Diethyl Pyrocarbonate CAS 1609-47-8

Factory wholesale Diethyl Pyrocarbonate CAS 1609-47-8

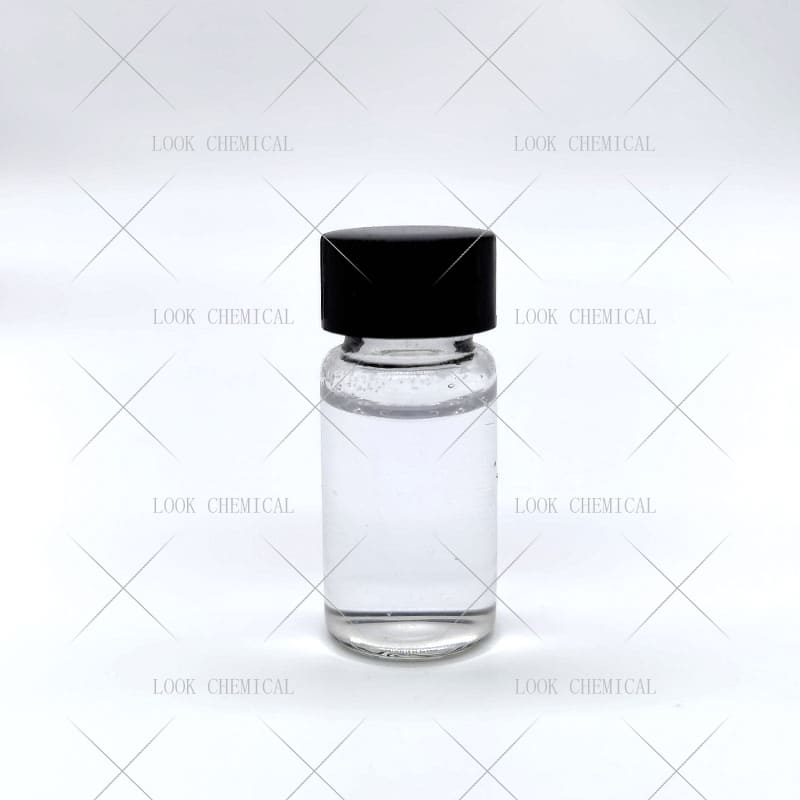

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diethyl Pyrocarbonate

CAS: 1609-47-8

MOQ: 1KG

Directory Guidance on Diethyl Pyrocarbonate

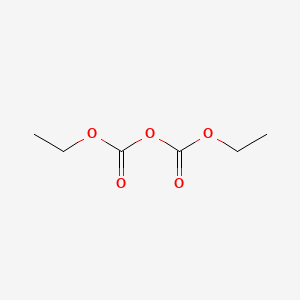

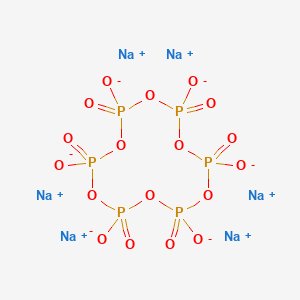

Chemical Structure

Basic Info:

| Melting point | 69℃ |

| Boiling point | 93-94 °C18 mm Hg(lit.) |

| density | 1.12 g/mL at 20 °C |

| refractive index | n20/D 1.398(lit.) |

| Fp | 157 °F |

Diethyl Pyrocarbonate Introduction:

Diethyl Pyrocarbonate (abbreviated as DEPC) is a highly reactive organic compound with the chemical formula C6H10O5. At room temperature, it is a colorless and transparent liquid with a faint estle-like characteristic odor. Its molecular structure contains two ethoxy carbonyl oxygen groups. This unique chemical configuration endows it with excellent electrophilicity and crosslinking ability.

As an important member of carbonate compounds, Diethyl Pyrocarbonate shows relative stability at room temperature, but it is prone to hydrolysis reactions in water or alcohol solvents, generating carbon dioxide and ethanol.This feature makes it particularly valuable in industrial scenarios that require controlled reactions. The compound needs to be stored in a cool environment away from light. It is recommended to fill it with inert gas to delay decomposition during long-term storage. Its vapor pressure is low, but its volatility is still higher than that of ordinary organic solvents. Ventilation protection should be taken into account during operation.

From the perspective of chemical properties, the activity of Diethyl Pyrocarbonate mainly stems from the bicarbonate structure in the molecule. Under specific conditions, this structure can effectively covalently bind with nucleophilic groups such as amino and thiol groups in biological macromolecules. This characteristic makes it hold an important position in the field of biochemistry.

In a ph-neutral aqueous solution, the half-life of Diethyl Pyrocarbonate is approximately 30 minutes. As the temperature rises or the pH value changes, its decomposition rate significantly increases. It is worth noting that the reaction of Diethyl Pyrocarbonate with primary amine-containing substances generates stable ethyl carbamate derivatives. This irreversible reaction mechanism lays the foundation for its fundamental role in multiple application fields.

In terms of the preparation process, industrial-grade Diethyl Pyrocarbonate is mainly produced through the condensation reaction of ethyl chloroformate under alkaline conditions. During the production process, the reaction temperature must be strictly controlled between 0 and 5℃ to prevent side reactions from generating impurities such as diethyl carbonate. Modern production processes mostly employ continuous flow reactors to enhance product purity. Through molecular distillation technology, the purity can be increased to over 99.5%.

The quality control stage focuses on moisture content and free chlorine indicators. The former needs to be kept below 50ppm to ensure storage stability, while the latter is precisely determined by the iodometric method. At present, the major global producers are concentrated in Europe, America and Asia. There are subtle differences in the content of residual solvents and metal ions among products from different manufacturers.

Nature and Specifications:

| Item | Specification |

| Product Name | Diethyl Pyrocarbonate |

| CAS No. | 1609-47-8 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 157 °F |

| storage temp. | 2-8°C |

| solubility | 95% ethanol: soluble4.5g/10 mL, clear, colorless |

| form | Liquid |

| color | APHA: ≤20 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Uses of Diethyl Pyrocarbonate

Diethyl Pyrocarbonate has numerous and profound applications in chemical synthesis, notably as an irreplaceable part of organic synthesis for various fine chemicals. Furthermore, in drug synthesis it acts as an intermediate for synthesizing multiple drugs; when synthesizing antibiotic drugs specifically it participates in building specific structural fragments while its unique functional groups react directly with biologically active molecules like amino acids and sugars to form compounds with antibacterial activity.

In the synthesis of cardiovascular drugs, Diethyl Pyrocarbonate can introduce functional groups such as ethoxy through a specific reaction path to regulate the polarity and bioavailability of drug molecules, thereby enhancing the therapeutic effect of drugs on cardiovascular diseases and making important contributions to human health.

In the field of pesticides, Diethyl Pyrocarbonate is also one of the important raw materials. It can be used to synthesize a variety of highly efficient insecticides, fungicides and herbicides. For instance, in the synthesis of certain new types of insecticides, it can react with organophosphorus compounds to generate organophosphorus insecticides with high toxicity and low residue. Such insecticides have a remarkable effect in controlling agricultural pests and can effectively increase the yield and quality of crops.

In the synthesis of fungicides, Diethyl Pyrocarbonate can react with nitrogen-containing heterocyclic compounds to form fungicides with broad-spectrum antibacterial activity, which can inhibit and kill various crop pathogens, ensuring the smooth progress of agricultural production. In terms of herbicide synthesis, it can change the structure and properties of herbicide molecules by introducing specific functional groups, making them more selective and safe, effectively eliminating weeds in farmland, reducing the adverse effects of weeds on crop growth, and promoting the sustainable development of agricultural production.

Diethyl Pyrocarbonate also holds great relevance in materials science. It plays an essential part in the synthesis and modification of polymer materials, particularly polyurethane materials. When creating polyurethane molecules it acts as an extender/crosslinking agent, participating in their formation via ester/ether bonds that interact with amino ester groups present within polyurethane to form more complex network structures which improve mechanical properties, heat resistance, chemical corrosion resistance resistance – significantly improving mechanical properties as well as chemical corrosion resistance resistance of polyurethane materials significantly.

Diethyl Pyrocarbonate can be used to modify epoxy resin with special properties by reacting with its epoxy groups, producing modified epoxy resin with lower shrinkage rate, higher bond strength and improved electrical insulation performance during curing process. It has become an invaluable material support for modern industry development.

Contact Us

The advantages of Diethyl Pyrocarbonate

In terms of product advantages, Diethyl Pyrocarbonate has significant efficacy advantages compared to traditional disinfectants. Its broad-spectrum antibacterial properties cover Gram positive bacteria, Gram negative bacteria, and various fungi, with a minimum inhibitory concentration (MIC) two orders of magnitude lower than that of sodium benzoate.

In terms of action speed, a 0.1% concentration solution can completely inactivate Escherichia coli within 30 seconds, and this rapid bactericidal ability makes it outstanding in handling sudden microbial contamination events. More importantly, its decomposition products are carbon dioxide and ethanol, which do not produce carcinogenic byproducts such as trihalomethanes like chlorine containing disinfectants, making it irreplaceable in areas with strict environmental requirements.

In terms of safety performance, Diethyl Pyrocarbonate demonstrates excellent safety in use. Although the original solution is irritating, the solution at the working concentration has extremely low toxicity to mammalian cells, with an oral LD50 of 2300mg/kg (rat), which is considered practically non-toxic. Its half-life in the environment does not exceed 24 hours and does not cause bioaccumulation effects.

Compared with quaternary ammonium salt disinfectants, it is less likely to induce microbial resistance, thanks to its unique protein modification mechanism. Within the scope of compliant use, the processed materials do not require additional washing steps, saving water resources and avoiding the risk of cross contamination. This ease of operation makes it widely popular in industrial production.

From an economic perspective, the unit usage cost of Diethyl Pyrocarbonate is significantly competitive. Although the unit price of raw materials is higher than that of ordinary preservatives, its ultra-high sterilization efficiency results in an actual addition amount of only 1/50-1/100 of traditional products. In the pharmaceutical industry, using it for equipment sterilization can shorten the production batch interval time, thereby increasing the annual production capacity of a single fermentation tank by 15% -20%.

After food processing enterprises adopt its sterilization process, the average shelf life of products is extended by 30%, and the market expansion benefits brought by the expansion of transportation radius far exceed the cost increase of preservatives. More noteworthy is that the treatment with Diethyl Pyrocarbonate does not alter the physicochemical properties of the product, avoiding quality degradation losses caused by additives.

In terms of stability, the storage stability of Diethyl Pyrocarbonate under closed conditions far exceeds that of similar products. The original solution can be stably stored for 24 months in nitrogen protected aluminum cans, with a loss rate of less than 2% of active ingredients. The prepared working solution maintains activity for more than 8 hours within the pH range of 5-7, which is particularly suitable for situations that require long-term antibacterial activity.

Unlike chlorine containing preparations that are susceptible to deactivation by organic matter, it can still maintain a sterilization efficiency of over 90% in complex systems containing proteins or sugars. The characteristic of complete decomposition of residual Diethyl Pyrocarbonate during high-temperature and high-pressure sterilization enables it to be perfectly integrated with terminal sterilization processes in the production of sterile preparations.

The compatibility advantage enables Diethyl Pyrocarbonate to work well with various industrial systems. In plastic product processing, it does not cause oxidative degradation of polymer materials like ozone, nor does it corrode metal equipment like peracetic acid. Its water solubility makes it easy to automate feeding through existing pipeline systems and seamlessly integrate with existing processes such as membrane filtration and pasteurization.

In the daily chemical industry, it has excellent compatibility with surfactants and will not cause flocculation or stratification, which is crucial for maintaining the appearance quality of transparent solution systems. These characteristics jointly contribute to the irreplaceable position of Diethyl Pyrocarbonate in multiple industrial fields.

Product Package picture:

Related References:

Chemicalbook-Diethyl Pyrocarbonate

Diethyl Pyrocarbonate Manufacturer

Contact Us

As an experienced Diethyl Pyrocarbonate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diethyl Pyrocarbonate CAS 1609-47-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.