Di-2-Ethylhexyl Azelate CAS 103-24-2

Factory wholesale Di-2-Ethylhexyl Azelate CAS 103-24-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Di-2-Ethylhexyl Azelate

CAS: 103-24-2

MOQ: 1KG

Directory Guidance on Di-2-Ethylhexyl Azelate

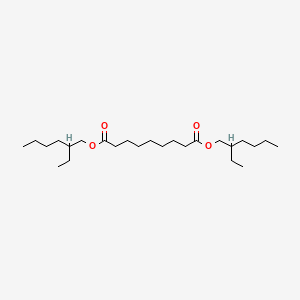

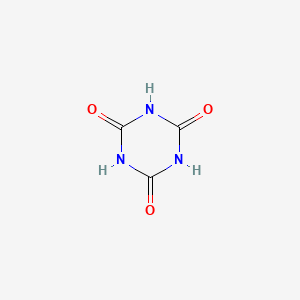

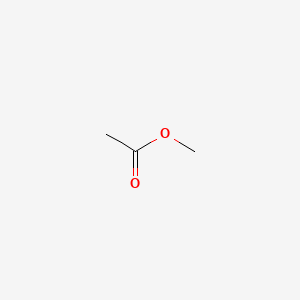

Chemical Structure

Basic Info:

| Melting Point | -67°C |

| Boiling Point | >282°C |

| Density | 0,92 g/cm3 |

| Pour Point | -76 |

Di-2-Ethylhexyl Azelate Introduction:

Di-2-Ethylhexyl Azelate is an important organic compound with the chemical formula C₃₃H₆₂O₄, and it belongs to ester derivatives. Di-2-Ethylhexyl Azelate usually presents as a colorless or light yellow transparent oily liquid at room temperature. It has extremely low volatility and a relatively high boiling point. Its physical properties are stable and it is not easily affected by changes in external temperature or humidity.

Its viscosity is moderate and its fluidity is good, demonstrating excellent processing performance in industrial applications. Due to the presence of both polar ester groups and non-polar alkyl chains in the molecule, this substance exhibits certain solubility in both polar and non-polar media, which lays a foundation for its application in various fields.

Di-2-Ethylhexyl Azelate has relatively stable chemical properties, and its molecular structure gives it good compatibility and durability. This structure enables it to effectively reduce the glass transition temperature of polymers in a variety of material systems and enhance the flexibility and processability of materials.

The molecular structure of Di-2-Ethylhexyl Azelate does not contain groups that are prone to hydrolysis, so it can still maintain the durability of its performance in a humid environment. Such characteristics make this compound play an irreplaceable role in fields such as plastic processing, rubber products, and lubricant formulation.

In terms of safety, the toxicological data of Di-2-Ethylhexyl Azelate show that it has low acute toxicity and less irritation to the skin and mucous membranes, which meets the environmental protection and health standards of most industrial products. Although its biodegradability is relatively limited, in conventional industrial use scenarios, reasonable process control and waste management can effectively reduce the potential impact on the environment.

From the perspective of market development, Di-2-Ethylhexyl Azelate, as a high-performance plasticizer and lubricant additive, its demand is closely related to the growth of downstream fields such as the plastic industry and the automotive manufacturing industry. In recent years, with the expansion of emerging industries such as new energy vehicles and wearable devices, the demand for high-performance materials has driven the technological iteration of this compound.

Nature and Specifications:

| Item | Specification |

| Product Name | Di-2-Ethylhexyl Azelate |

| CAS No. | 103-24-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 211 °C |

| Storage Temp. | Refrigerator |

| Solubility | Chloroform (Slightly), Methanol (Slightly) |

| Form | Oil |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Di-2-Ethylhexyl Azelate

Di-2-Ethylhexyl Azelate plasticizer has become increasingly prominent in plastic processing. This compound boasts excellent compatibility with high molecular materials like polyvinyl chloride (PVC) and polyurethane (PU), providing significant increases in flexibility and low temperature impact resistance of materials that use it as plasticizer.

Compared with traditional phthalate plasticizers, Di-2-Ethylhexyl Azelate performs better in terms of migration resistance and durability, and is particularly suitable for scenes with high requirements for material stability, such as automotive interiors and medical catheters. During high-temperature processing, its thermal stability can effectively inhibit the yellowing or embrittlement of plastic products and ensure the consistency of the mechanical properties of the final product.

Di-2-Ethylhexyl Azelate can enhance dynamic vulcanization systems and accelerate filler dispersion to enhance anti-age performance of rubber products. When added to special rubber products requiring oil resistance and chemical medium resistance, its addition can significantly extend service life under complex working conditions; its use has even been applied successfully in high-end fields like aerospace seals.

Compared with traditional mineral oils, lubricants containing Di-2-Ethylhexyl Azelate have a wider operating temperature range and can maintain stable lubrication performance within the range of -40℃ to 200℃. This characteristic enables it to be widely applied in equipment with extremely high requirements for lubrication reliability, such as precision machinery and wind power gearboxes.

The coatings and inks industry takes advantage of its excellent solubility and leveling properties to use it as a resin modifier or solvent. In the ultraviolet curing system, Di-2-Ethylhexyl Azelate can adjust the surface tension of the coating, improve the dispersion state of pigments, and enhance the scratch resistance of the coating film at the same time.

For water-based coating systems, when Di-2-Ethylhexyl Azelate is used as a co-solvent, it can not only improve the film-forming quality but also will not significantly increase the content of volatile organic compounds (VOC), meeting the increasingly strict environmental protection regulations. In printing inks, this substance helps regulate viscosity and improve printability, and is particularly suitable for high-speed rotary printing processes.

Furthermore, in personal care products, Di-2-Ethylhexyl Azelate is used in small amounts in the formulation systems of cosmetics such as body lotions and sunscreens due to its mild skin affinity.

Di-2-Ethylhexyl Azelate’s potential as an enhancer for transdermal drug absorption has garnered much interest within medicine, with studies proving its ability to increase bioavailability while simultaneously decreasing side effects; however, these applications remain subject to strict regulatory scrutiny at present and commercial cases remain limited.

The Advantages Of Di-2-Ethylhexyl Azelate

Di-2-Ethylhexyl Azelate’s strength as a performance chemical lies in its versatility. When compared with single-purpose chemicals, this substance has proven itself as industry leaders across multiple technical dimensions such as plasticization, lubrication and dispersion through its molecular design.

Di-2-Ethylhexyl Azelate’s wide temperature stability makes it stand out. Not only can it withstand instantaneous high temperatures of over 200degC during injection molding, but also maintain flexible elastomeric materials in cold environments. This wide spectrum of performance drastically simplifies formula development processes, enabling downstream companies to accomplish multiple modification goals through one additive and significantly improve production efficiency.

Di-2-Ethylhexyl Azelate stands out as an economical alternative, boasting impressive cost-effectiveness in terms of economics. Although its unit mass cost may be slightly higher than other plasticizers, only 70-80% of traditional products are required to achieve similar modifications effects. Furthermore, its anti-migration properties reduce performance degradation caused by additive loss, extend product replacement cycles and consequently lower total life cycle costs; its retention rate exceeds 95% in recycling systems requiring secondary processing, significantly increasing recycled plastics’ added value further.

Di-2-Ethylhexyl Azelate is an exceptional material when it comes to process adaptability. Its viscosity range meets mainstream processing equipment specifications, enabling large-scale application without modification of production lines. When processed via twin-screw extrusion and mixing processes, its flow characteristics help shorten plasticizing times by 5-8% while simultaneously decreasing energy usage by the same percentage. Furthermore, when applied for small batch production that requires precise metering applications its physical stability ensures feeding accuracy reducing quality fluctuations caused by material agglomeration or stratification.

As part of technological innovation, the Di-2-Ethylhexyl Azelate synthesis process is being continuously optimized. By employing a new catalytic system and increasing esterification reaction conversion to over 99.2% while decreasing by-product production by 60%. Some companies have employed continuous production processes, which has reduced single batch production cycles from 12 hours to 4 hours and thus tripled their capacity while simultaneously decreasing unit energy usage. As for quality control, near-infrared online monitoring technology has enabled real-time control of key indicators and consistency of product batches has reached PPB level; fully meeting stringent material uniformity requirements of high-end fields like automobiles and medical care.

Environmental protection attributes of Di-2-Ethylhexyl Azelate make it an invaluable competitive edge. Due to REACH regulations and GB standards limiting hazardous substances, market space for traditional benzene-containing plasticizers continues to reduce significantly. Di-2-Ethylhexyl Azelate does not contain restricted phthalates; its ecotoxicity data meets all EU SVHC list requirements ensuring certification for final products; additionally some improved versions have passed biodegradability tests with half lives up to 30% shorter than traditional ones thus creating conditions for growth of an eco-friendly market.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Di-2-Ethylhexyl Azelate

Di-2-Ethylhexyl Azelate Manufacturer

Contact Us

As an experienced Di-2-Ethylhexyl Azelate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Di-2-Ethylhexyl Azelate CAS 103-24-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.