Dextrin Powder CAS 9004-53-9

Factory wholesale Dextrin Powder CAS 9004-53-9

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dextrin Powder

CAS: 9004-53-9

MOQ: 1KG

Directory Guidance on Dextrin Powder

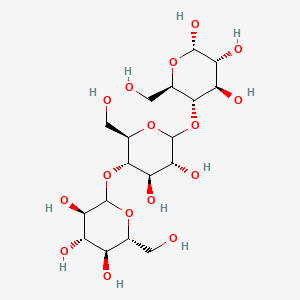

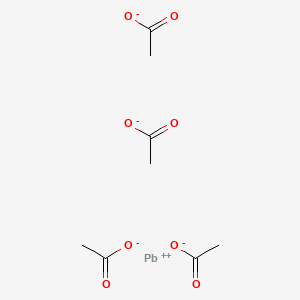

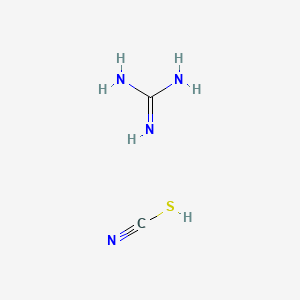

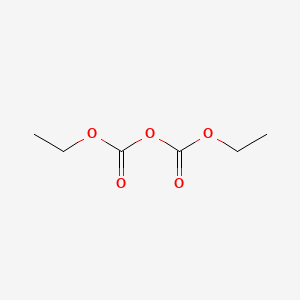

Chemical Structure

Basic Info:

| Melting point | 53.75-54 °C |

| Density | 0.8 g/cm3 |

| Storage temp. | Store at RT. |

| Solubility | H2O: 0.1 g/mL hot, complete, yellow to very deep yellow |

Dextrin Powder Introduction:

Dextrin Powder is a type of low molecular weight carbohydrate obtained by acid hydrolysis, enzymatic hydrolysis or thermal hydrolysis of starch. Its molecular structure is between starch and maltodextrin, and is usually composed of D-glucose units connected by α-1,4 glycosidic bonds and α-1,6 glycosidic bonds.

Depending on the production process, dextrin can be divided into three categories: white dextrin, yellow dextrin and baked dextrin. White dextrin is mainly prepared by acid catalysis, while yellow dextrin is produced by dry thermal cracking reaction. This diverse preparation method makes the molecular weight distribution range of dextrin wide, usually between 1,000-50,000 Daltons, which provides the basic conditions for its application in different fields.

From the perspective of physical and chemical properties, Dextrin Powder has significant water solubility and viscosity. Its solution viscosity increases exponentially with increasing concentration. This rheological characteristic makes it show unique value in industrial applications. Compared with starch, dextrin has significantly improved cold water solubility and can be completely dissolved at 25°C. This property greatly expands its application possibilities in liquid systems.

In terms of thermal stability, it can withstand short-term heat treatment at 120°C without obvious decomposition, but it will degrade to varying degrees under strong acid or alkali conditions. It is worth noting that the residual hydroxyl groups on the dextrin molecular chain give it good chemical reactivity, and specific functions can be obtained through modification methods such as esterification and etherification.

Compared with similar carbohydrate products, Dextrin Powder has unique advantages in solubility, film-forming properties and thermoplasticity. Compared with maltodextrin, it contains more branched structures, and this molecular configuration makes its solution more pseudoplastic. Compared with cyclodextrin, its molecular weight distribution range is wider, and this polydispersity becomes an advantage in specific applications. These differentiated properties make it find irreplaceable application space in many industrial fields.

Nature and Specifications:

| Item | Specification |

| Product Name | Dextrin Powder |

| CAS No. | 9004-53-9 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Dorm | powder |

| Color | yellow |

| Odor | odorless |

| Biological source | potato starch |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Dextrin Powder

Dextrin Powder has become an indispensable material in industrial production systems due to its unique physical-chemical properties. One industry that relies heavily on Dextrin Powder for use is food production systems; specifically in terms of its unique thickening and stabilizing abilities: dairy products, baked goods, seasonings etc. In ice cream production it can inhibit crystal growth while improving texture; its water holding capacity helps meat processing yield. Most noteworthy of all is microencapsulation technology which helps stabilize food components by encasing flavor compounds or nutritional enhancers into food ingredients thereby significantly improving ingredient stability compared to standard formulation methods alone.

Dextrin Powder remains in great demand in the pharmaceutical industry, especially solid dosage form fields such as tablet production. As an excellent excipient for tablet production, Dextrin Powder helps improve flowability of materials and regulate drug release rate while sustained-release preparations with specially modified Dextrin can form stable hydrogel networks for controlled release function of drugs. Furthermore, injection use has witnessed breakthroughs while its biocompatibility makes it an attractive candidate material for vaccine adjuvants; all this serves to demonstrate both its functional diversity as well as reflect an urgent demand in pharmaceutical industries for safe excipients.

Dextrin Powder’s use and development in the chemical industry is growing increasingly diverse. Adhesives containing Dextrin Powder can be combined with synthetic polymers like polyvinyl alcohol to produce environmentally-friendly adhesives with adhesion and holding strength exceeding industrial standards, while its film-forming properties have proven useful as film forming agents in water-based coating systems to increase glossiness, wear resistance, gloss retention, gloss enhancement, film-forming agent properties are attracting much interest, textile printing/dyeing enterprises utilize its film-forming properties to produce pulp types that improve yarn strength as well as facilitate subsequent desizing processes.

Dextrin Powder’s application in environmental protection has expanded significantly. Cyclodextrin-based adsorbent materials offer significant selective adsorption effects on heavy metal ions in sewage treatment processes; with maximum capacities exceeding 200mg/g. Research and development efforts related to biodegradable materials have seen considerable strides made, especially when combined with bio-based polymers like polylactic acid. Mechanical properties and degradation rates of the materials produced meet practical specifications, while in terms of soil improvement research their derivatives as water retaining agents is making significant advances. Their water holding capacities often surpass that of traditional materials by 3-4-5 times!

Dextrin Powder’s functionality continues to expand across emerging technology fields. In 3D printing materials systems, its rheological properties make it an ideal substrate for bioinks; research into animal trials is well underway. In energy storage applications, researchers utilize its carbonized products to prepare supercapacitor electrode materials with specific surface areas of over 2000m 2/g; such applications not only increase their added value but also drive technological innovation within various industries.

The Advantages Of Dextrin Powder

The industrial competitiveness of Dextrin Powder lies in its unique performance combination and continuous technological innovation. From a molecular design perspective, it has a rich range of modifiable sites that can be chemically modified to give specific functions to the product. For example, hydroxypropylation treatment can significantly improve water solubility, while acetylation modification enhances film-forming properties. These targeted modification techniques enable products to accurately meet the needs of different industries. This functional adjustability gives it an advantage in market competition, especially in modern industrial systems where personalized needs are increasingly prominent.

The economy of production process constitutes the core competitiveness of Dextrin Powder. The main raw material starch has a wide range of sources and stable prices, and the large-scale cultivation of crops such as corn and cassava provides reliable guarantees for the industry. The modern continuous production technology has reduced the energy consumption by more than 40% compared with the traditional process. The improvement of key equipment such as spray drying has raised the product yield to more than 95%. What is even more commendable is that the by-products generated during the production process, such as glucose syrup, can be recycled, and this resource utilization model significantly reduces overall costs.

The stability of product performance is a key factor in Dextrin Powder’s market recognition. The strict quality control system ensures that different batches of products are highly consistent, the viscosity fluctuation range is controlled within ±5%, and the pH value deviation does not exceed 0.3 units. This stability is particularly important in the field of pharmaceuticals and other fields with strict regulatory supervision. The company has established a complete GMP management system to ensure that the products meet the standards of international pharmacopoeias such as USP and EP. Long-term storage experiments show that under standard storage conditions, its key indicators have no significant changes within three years.

The environmentally friendly features enhance the sustainable development value of Dextrin Powder. The entire lifecycle analysis shows that its carbon emissions are more than 60% lower than similar petroleum based products, and its fully biodegradable characteristics eliminate environmental residual risks. In the context of increasingly strict environmental regulations, this green attribute has become an important factor in market competition. Through process optimization, production enterprises have reduced the COD value of wastewater to below 100mg/L, achieving direct discharge standards and further strengthening the environmental advantages of their products.

Technological innovation continues to drive product upgrades. Nano-processing technology controls the particle size distribution of Dextrin Powder within the range of 100-500 nanometers. This ultrafine powder shows unique advantages in transdermal drug delivery systems. The breakthrough in microencapsulation technology has increased the embedding rate to more than 90%, providing a new solution for the protection of active ingredients. The introduction of molecular imprinting technology has enabled Dextrin Powder-based materials to have specific recognition capabilities, opening up new application scenarios in the field of separation and purification. These technological innovations not only consolidate the traditional market position, but also create new growth points.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Dextrin Powder

Dextrin Powder Manufacturer

Contact Us

As an experienced Dextrin Powder manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dextrin Powder CAS 9004-53-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.