Decabromodiphenyl Oxide CAS 1163-19-5

Decabromodiphenyl Oxide CAS 1163-19-5

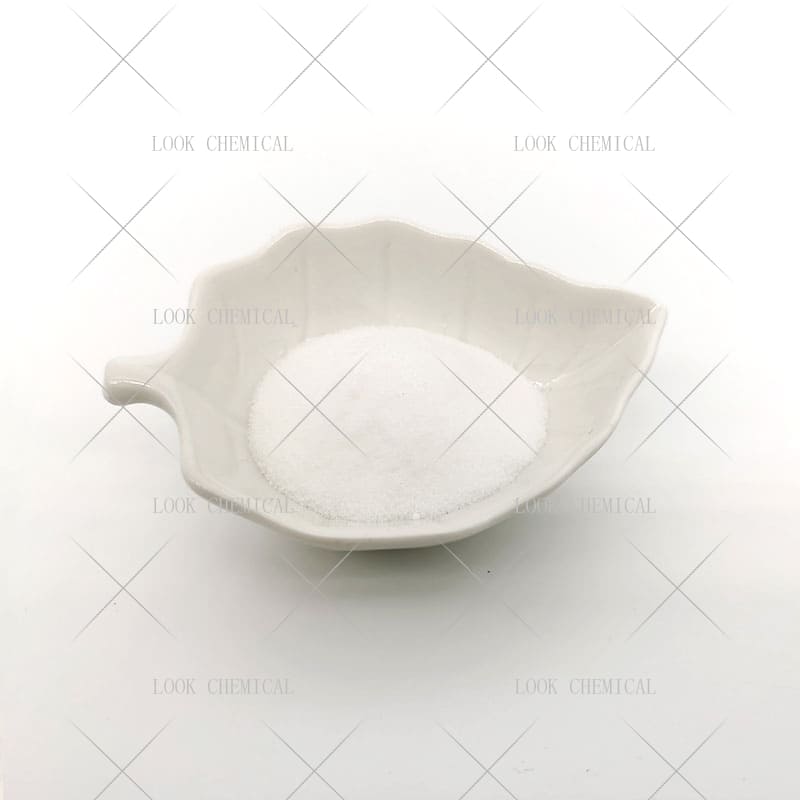

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Decabromodiphenyl Oxide

CAS: 1163-19-5

MOQ: 1KG

Directory Guidance on Decabromodiphenyl Oxide

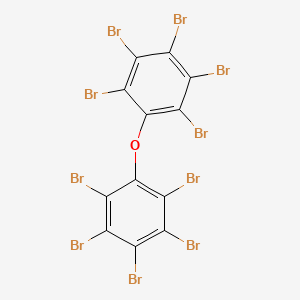

Chemical Structure

Basic Info:

| Melting point | >300 °C(lit.) |

| Boiling point | 425°C |

| density | 3 g/cm3 |

| vapor pressure | 0Pa at 21℃ |

| refractive index | 1.5000 (estimate) |

| Fp | -12 °C |

Product Introduction:

Decabromodiphenyl Oxide is a brominated flame retardant with the chemical formula C₁₂Br₁₀O and the CAS number 1163-19-5. Its molecular structure consists of two benzene rings connected by an ether bond, and five bromine atoms are uniformly substituted on each benzene ring. This highly brominated property makes it have excellent flame retardant properties, and it releases bromine free radicals through high-temperature cracking, effectively interrupting the combustion chain reaction. It has a white to light yellow powder appearance, a melting point range of 285–315°C, and a thermal decomposition temperature of more than 320°C, which is suitable for high-temperature processing environments.

In industry, the synthesis of Decabromodiphenyl Oxide is mainly achieved through the direct bromination reaction of diphenyl ether. Using diphenyl ether as a raw material, it reacts with liquid bromine at a specific temperature and pressure under the catalysis of Lewis acid (such as iron or aluminum halide), and a decabrominated product is generated after multiple steps of substitution. This process requires strict control of the degree of bromination to avoid the formation of by-products (such as octabromo or nonabromodiphenyl ether). After subsequent purification through crystallization, washing and drying, an industrial-grade product with a purity of more than 98% is finally obtained.

From the perspective of environment and toxicology, Decabromodiphenyl Oxide has caused widespread controversy due to its high fat solubility and persistence. Early studies have shown that it has a risk of bioaccumulation in organisms, but recent studies have confirmed that its environmental metabolic rate is higher than expected, and its half-life in water and soil is significantly shorter than other brominated flame retardants (such as pentabromodiphenyl ether). The International Program on Chemical Safety (IPCS) assesses that under compliant use scenarios, the impact of Decabromodiphenyl Oxide on the ecosystem is controllable.

At present, the global production capacity of Decabromodiphenyl Oxide is concentrated in China, the United States and Israel. As the largest producer, China has an annual output of more than 100,000 tons, accounting for more than 65% of the global market share. The production process continues to be optimized, such as using microreactor technology to improve bromination efficiency and reduce the proportion of by-products. At the same time, the company reduces bromine vapor emissions through a closed-loop production system, reducing unit energy consumption by 18%.

Nature and Specifications:

| Item | Specification |

| Product Name | Decabromodiphenyl Oxide |

| CAS No. | 1163-19-5 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 2-8°C |

| solubility | <0.0001mg/l |

| form | Solid |

| color | White to Light Brown |

| Water Solubility | <0.1 g/100 mL at 20 ºC |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As a highly efficient additive flame retardant, Decabromodiphenyl Oxide is mainly used in the field of polymer materials. In the electrical and electronic industry, its synergistic system with antimony trioxide is widely used in the flame retardant modification of engineering plastics such as ABS and HIPS, which can make the materials meet the UL94 V-0 flame retardant standard. Typical applications include computer casings (addition amount 12-15%), TV high-voltage packages (addition amount 18-22%) and lithium-ion battery separator coatings. According to statistics from the European Plastics Association, about 32% of electronic plastic products in the world still rely on Decabromodiphenyl Oxide as a core flame retardant ingredient.

In the construction field, Decabromodiphenyl Oxide is added to insulation materials such as polyurethane foam and extruded polystyrene (XPS) to improve their fire resistance. For example, the US building code requires that the oxygen index of the exterior wall insulation material of high-rise buildings must be ≥28%. The addition of Decabromodiphenyl Oxide can increase the XPS oxygen index from 18% to 32%. In addition, in the transportation industry, it is used in automotive interior parts (seat foam materials, instrument panels) and aviation cargo hold linings, meeting the requirements of flame retardant regulations such as FMVSS 302.

In recent years, in response to the upgrading of environmental protection regulations, the application technology of Decabromodiphenyl Oxide has shown two major innovative directions: one is to develop microencapsulation technology to reduce its escape during material processing through silica or polyurea coating; the other is to compound with nanoclay, carbon nanotubes, etc. to build a synergistic flame retardant network and reduce the addition amount to less than 8%. For example, the Deca-BDE/montmorillonite composite system developed by Japan’s Kaneka Chemical has reduced smoke generation by 40% while maintaining the same flame retardant efficiency.

At the market level, although the EU has imposed restrictions on Decabromodiphenyl Oxide based on the REACH regulation, its demand in developing countries continues to grow. The annual demand growth rate of the plastic processing industry in India, Southeast Asia and other places reached 7.2%, mainly used for wire and cable sheath materials (accounting for 45%) and home appliance accessories (accounting for 30%).

The competitive advantage of Decabromodiphenyl Oxide is first reflected in the balance between flame retardant efficiency and economy. Experimental data show that its flame retardant efficiency (flame retardant effect provided by unit mass of bromine) is 23% higher than that of hexabromocyclododecane, while the cost is only 1/3 of that of phosphorus flame retardants. Adding 15% Decabromodiphenyl Oxide to polypropylene can increase the limiting oxygen index from 17% to 29%, and the impact on the material’s impact strength (decreased ≤8%) is significantly lower than that of the magnesium hydroxide flame retardant system (decreased 15–20%).

Thermal stability is another core advantage. At the processing temperature of nylon 6 (260–280°C), the volatilization loss rate of Decabromodiphenyl Oxide is only 0.5%, which is much lower than tetrabromobisphenol A (2.8%) and brominated epoxy resin (1.9%). This allows it to maintain stable performance in high-temperature molding processes such as injection molding and extrusion. At the same time, it has excellent compatibility with the polymer matrix and will not cause frosting or surface precipitation problems. It is especially suitable for automotive interior parts with strict requirements on surface quality.

From the perspective of life cycle assessment (LCA), Decabromodiphenyl Oxide has better environmental performance than some alternatives. A comparative study by the Fraunhofer Institute in Germany shows that the carbon emission equivalent of producing 1 ton of Decabromodiphenyl Oxide flame-retardant HIPS plastic is 12% lower than that of using phosphorus-nitrogen flame retardants, because the synthesis process of the latter involves more high-energy reaction steps. In addition, Decabromodiphenyl Oxide has outstanding recycling compatibility. In the process of plastic recycling and granulation, its flame retardant efficiency retention rate can reach more than 85%.

Despite the pressure of environmental protection, there are still technical bottlenecks in completely replacing Decabromodiphenyl Oxide. Existing alternatives such as decabromodiphenyl ethane (DBDPE) have similar flame retardant efficiency, but their thermal stability is poor (decomposition temperature 280°C), which limits their application in high-temperature plastics; polymer flame retardants (such as brominated polystyrene) are more environmentally friendly, but the cost is as high as 2.5 times that of Deca-BDE. Therefore, in high-end fields such as aerospace and nuclear power equipment, Decabromodiphenyl Oxide is still an irreplaceable solution.

In the future, the development of Decabromodiphenyl Oxide will focus on green upgrades. For example, using bio-based diphenyl ether raw materials to reduce carbon footprint, or developing ionic liquid catalytic systems to improve the economic efficiency of synthetic atoms. As flame retardant regulations shift from single performance indicators to comprehensive sustainability evaluation, this classic flame retardant will remain competitive in specific application scenarios.

Contact Us

Product Package picture:

Related References:

chemicalbook-Decabromodiphenyl Oxide

Decabromodiphenyl Oxide Manufacturer

Contact Us

As an experienced Decabromodiphenyl Oxide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Decabromodiphenyl Oxide CAS 1163-19-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.