Bromoethane CAS 74-96-4

Factory wholesale Bromoethane CAS 74-96-4

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Bromoethane

CAS:74-96-4

MOQ: 1KG

Directory Guidance on Bromoethane

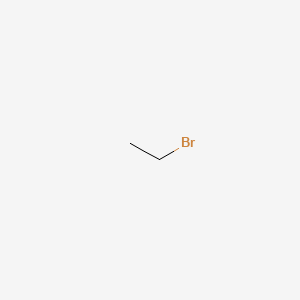

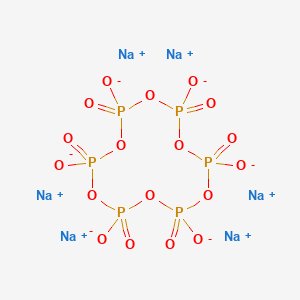

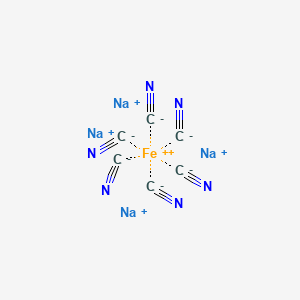

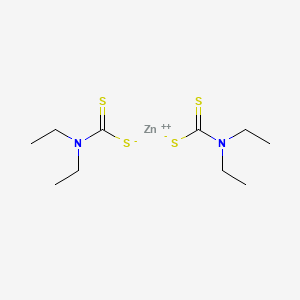

Chemical Structure

Basic Info:

| Melting Point | -119 °C |

| Boiling Point | 37-40 °C(lit.) |

| Density | 1.46 g/mL at 25 °C(lit.) |

| Vapor Density | ~3.75 (vs air) |

Bromoethane Introduction:

Bromoethane (C ₂ H ₅ Br) is an important halogenated hydrocarbon compound formed by replacing one hydrogen atom in an ethane molecule with a bromine atom. Its molecular structure is simple, but its chemical properties are active, and it plays an irreplaceable role in organic synthesis, industrial production, and laboratory research.

As a colorless and transparent liquid, bromoethane is volatile at room temperature, with a boiling point of about 38.4℃ and a density of 1.46 g/cm³. It is slightly soluble in water but easily soluble in organic solvents such as ethanol and ether. This physical property enables it to be used as a solvent in the reaction system and as a reactant in a variety of chemical transformations.

From the perspective of chemical properties, the bromine atom of bromoethane has a high electronegativity, which makes the C-Br bond have a strong polarity and is easily broken under the action of nucleophilic reagents. This property establishes its core position in substitution reactions. For example, in the classic SN2 reaction, it often reacts with hydroxide ions or amines as a substrate to produce ethanol or ethylamine derivatives. In addition, in the elimination reaction, it can remove HBr to generate ethylene under alkaline conditions. This type of reaction is widely used in the synthetic pathway of constructing carbon-carbon double bonds.

The main methods for industrial production of bromoethane include the substitution reaction of ethanol and hydrobromic acid, and the addition reaction of ethylene and hydrogen bromide. The former is usually carried out under the catalysis of concentrated sulfuric acid, and the nucleophilic substitution process is promoted by protonating the hydroxyl group of ethanol; the latter uses the direct combination of ethylene and HBr under specific conditions. This process route is widely adopted by modern industry due to its high reaction efficiency and few by-products.

During storage and transportation, bromoethane needs to be sealed and kept away from light, fire and oxidants, and its vapor may form an explosive mixture when mixed with air. Although its acute toxicity is relatively low, long-term exposure may cause damage to the central nervous system and liver and kidneys, so protective equipment must be equipped during operation and ensure good ventilation. It is worth noting that it degrades slowly in the atmosphere, and its potential damage to the ozone layer has attracted attention in the field of environmental protection, and research on related substitutes is continuing to advance.

From the perspective of molecular design, the structural characteristics of bromoethane determine its reactivity and selectivity. Compared with ethyl chloride, its C-Br bond energy is lower (about 276 kJ/mol) and its reaction activity is higher; compared with ethyl iodide, its cost is more advantageous and its storage stability is better.

Nature and Specifications:

| Item | Specification |

| Product Name | Bromoethane |

| CAS No. | 74-96-4 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Vapor Pressure | 25.32 psi ( 55 °C) |

| Refractive Index | n20/D 1.425(lit.) |

| Fp | -23 °C |

| Storage Temp. | Store below +30°C. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Bromoethane

In the industrial field, Bromoethane is an important ethylating agent and intermediate, widely used in the synthesis of dyes, fragrances and drugs. As an ethyl donor, the C-O, C-N and C-S bonds it participates in constructing are indispensable structural units for many functional molecules. For example, in pesticide production, Bromoethane is used to synthesize organophosphorus compounds with insecticidal activity;

In the dye industry, it is used as an ethylating agent to participate in the modification of anthraquinone dyes to enhance color fastness and dyeing performance. The demand for it in the pharmaceutical industry is particularly prominent, and the synthesis routes of many antibiotics, sedatives and anti-tumor drugs involve nucleophilic substitution reactions involving Bromoethane. Especially in the side chain modification of β-lactam antibiotics, the ethyl group it provides can effectively improve the lipid solubility and bioavailability of drugs.

In the field of electronic materials, Bromoethane is used as a precursor to participate in the synthesis of ethyl-containing silane coupling agents, which can significantly improve the interfacial bonding strength between polymer materials and inorganic fillers. In recent years, with the rapid development of fluorine-containing materials, its polymerization reaction with perfluoroolefins has become an important way to prepare special fluorinated surfactants. Such materials have unique value in fire-fighting foams and antifouling coatings.

The synthesis of agricultural chemicals is also inseparable from Bromoethane. As a synthetic intermediate of plant growth regulators, it introduces ethyl groups into specific molecular skeletons through nucleophilic substitution reactions, thereby regulating the biological activity of compounds. In the field of herbicides, its derivatives can interfere with the amino acid metabolic pathways of weeds and achieve selective weed control. In addition, some fumigant insecticides use it as an active ingredient, using its volatility and fat solubility to penetrate the insect cuticle and destroy the nerve conduction system.

At present, the application exploration of bromoethane in the field of new energy materials has attracted much attention. Researchers have found that it can improve the interfacial stability of lithium-ion batteries as an electrolyte additive and inhibit dendrite growth by preferentially decomposing to form a dense SEI film. In the synthesis of photovoltaic materials, the cross-coupling reaction in which it participates provides a new idea for the construction of conjugated polymers. Such materials show broad prospects in organic solar cells. Despite the pressure of environmental protection, its irreplaceable role in specific fields will continue to exist for a long time through process optimization and progress in recycling technology.

The Advantages Of Bromoethane

The core advantage of bromoethane is first reflected in its excellent balance between reactivity and controllability. Compared with chlorinated compounds, its higher reaction rate can shorten the synthesis cycle; compared with iodinated compounds, its milder reaction conditions are conducive to the construction of complex molecules. This characteristic makes it a preferred reagent in synthetic routes that require precise control of the reaction process.

From an economic perspective, bromoethane’s industrial production technology is mature, raw materials are easily available and have obvious cost advantages. The atomic utilization rate of ethylene addition method is close to the theoretical value, and the amount of three wastes generated is small, which is in line with the development direction of green chemistry. Compared with similar reagents, it has a higher unit reaction efficiency.

For example, in the ethylation reaction, its molar dosage can usually be reduced by 15%-20% compared with ethyl chloride, significantly reducing the cost of raw materials. In addition, the recycling of Bromoethane byproduct HBr has formed a mature process. After being captured and purified by an absorption tower, it can be used as a raw material for other production processes. This circular economy model further enhances its comprehensive competitiveness.

Compared with difficult-to-degrade alternatives such as perfluorinated compounds, it has a relatively short half-life in the natural environment (about 20 days) and can be gradually mineralized into harmless substances through photolysis and hydrolysis. This degradability allows it to maintain its application value under strict control.

From the perspective of technological development, the modification research of Bromoethane continues to promote its performance improvement. By developing a new catalyst system, the reaction conversion rate in which it participates has been increased from 85% in traditional processes to more than 98%. The application of nanocatalytic technology has significantly improved its enantiomeric selectivity in asymmetric synthesis, which has opened up new ways for the synthesis of chiral drugs.

In the field of green chemistry, researchers have successfully achieved its electrochemical regeneration and converted the reaction byproduct HBr back into Bromoethane. This closed-loop production process has brought resource utilization to a new level.

At present, the application potential of Bromoethane in high-end material manufacturing is constantly being explored. As a carbon source precursor, it shows unique advantages in the process of preparing carbon nanotubes by chemical vapor deposition. The decomposition temperature of ethyl perfectly matches the activation energy of the catalyst, and a high-purity oriented carbon nanotube array can be prepared.

In the synthesis of organic semiconductor materials, the cross-coupling reaction in which it participates can precisely control the molecular conjugation length, which plays a key role in optimizing the carrier mobility of the material. With the advancement of synthesis technology, it is expanding from traditional chemical raw materials to the preparation of high value-added functional materials. This transformation and upgrading has injected new impetus into its sustainable development.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Bromoethane

Bromoethane Manufacturer

Contact Us

As an experienced Bromoethane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Bromoethane CAS 74-96-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.