Alkyl Ketene Dimer CAS 144245-85-2

Free Sample Alkyl Ketene Dimer CAS 144245-85-2

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Alkyl Ketene Dimer

CAS: 144245-85-2

MOQ: 1KG

Directory Guidance on Alkyl Ketene Dimer

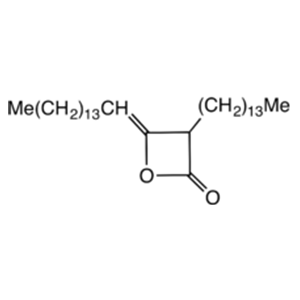

Chemical Structure

Basic Info:

| Product Name: | Alkyl Ketene Dimer |

| Synonyms: | Alkylketene dimer;AKD;PaperMaking CheMicals series;AKD WAX 1840;AKD WAX 1865;AKD CAS NO.144245-85-2;Alkyl Ketene Dimer – Liquid |

| CAS: | 144245-85-2 |

| EINECS: | 200-001-8 |

Product Introduction:

Alkyl Ketene Dimer (AKD for short) is an essential organic compound, often employed as a neutral sizing agent in papermaking industries. An unsaturated lactone, it usually presents as waxy solid with a melting point between 51degC and 52degC and an insoluble water form; its dissolvability in organic solvents such as ethanol, benzene, or chloroform is relatively stable while its molecular structure contains four-membered lactone ring which reacts with active hydrogen-containing compounds like cellulose to form stable b-ketoesters with strong sizing effects achieved as a sizing effect achieved.

Alkyl Ketene Dimer preparation involves two key steps. At first, high-carbon saturated fatty acids with carbon numbers between 14 to 18 react with phosphorus trichloride to form an acyl chloride intermediate; subsequent reactions with acid binding agents like triethylamine lead to self-polymerization that yields Alkyl Ketene Dimers with four-ring structures. The final product must typically be further emulsified to create an AKD emulsion with a solid content between 10%-15% for use in papermaking processes. Recently, thanks to advancements in synthetic and emulsification technology, its solid content can now reach 40% or greater while hydrolysis and migration tendency has also been effectively limited.

Alkyl Ketene Dimer offers numerous advantages as a reactive neutral sizing agent in papermaking. It can be used for internal sizing of various papers including coated, copy, archival and dictionary papers as well as high-quality writing papers; with an alkaline pH value reaching around 8.0 it has also been known as an alkaline sizing agent. Utilizing this AKD sizing can significantly enhance strength and optical properties as well as increasing fillers such as calcium carbonate to lower production costs; additionally durability and printability make this agent widely utilized in high-end production.

However, Alkyl Ketene Dimer can present several challenges in its application. Due to the large lactone ring present in its molecules, reaction rates with cellulose are slow, while stability of its emulsion is poor and subject to hydrolysis; which hinders its use for certain paper production. Thus researchers are hard at work improving AKD emulsification processes while creating high concentration, self-emulsifying products to meet industry demand for efficient yet stable sizing agents.

Alkyl Ketene Dimer (AKD), as an essential papermaking chemical, holds an invaluable place in the industry thanks to its superior sizing performance and environmental safeguarding properties. Furthermore, with advances in technology AKD is likely to expand further in application scope thus supporting further the advancement of papermaking industry.

Nature and Specifications:

| Item | Specification |

| Product Name | Alkyl Ketene Dimer |

| CAS No. | 144245-85-2 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | -196°C |

| CAS DataBase Reference | 144245-85-2 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Compared with traditional rosin sizing agents, paper sizing with Alkyl Ketene Dimer has higher weather resistance and mechanical strength, and is particularly suitable for high-end packaging paper, medical dialysis paper and other fields. In practical applications, AKD emulsion is usually compounded with additives such as cationic starch and polyacrylamide, and the sizing efficiency can reach 0.8-1.2kg/ton of paper, and the sizing degree is increased by 30%-50%.

The textile industry uses Alkyl Ketene Dimer for fabric waterproof finishing, and constructs a nano-scale hydrophobic film on the surface of natural fibers such as cotton and linen through a padding-baking process. The dynamic contact angle of fabrics treated with Alkyl Ketene Dimer can reach more than 145°, the hydrostatic pressure resistance exceeds 8kPa, and it can withstand 20 standard washing cycles. Compared with fluorinated waterproofing agents, the AKD system does not contain PFOA/PFOS, meets the requirements of OEKO-TEX® Eco-Passport certification, and has been successfully used in high-end textiles such as outdoor sportswear and medical protective clothing.

In the field of functional materials, Alkyl Ketene Dimer has shown unique value as an interfacial modifier. Adding 1%-3% AKD to polylactic acid (PLA) bio-based plastics can reduce its water vapor permeability by 40% while maintaining the material’s degradable properties; in lithium-ion battery separator coatings, the microporous structure formed by the blending of AKD and ceramic particles can increase the electrolyte absorption rate to 350%, significantly improving the battery rate performance.

Emerging application directions include: 1) Moisture barrier layer in electronic packaging materials, the water oxygen permeability (WVTR) of Alkyl Ketene Dimer film can be as low as 0.01g/m²·day; 2) 3D printing support materials, using its thermally induced phase change properties to achieve precise peeling; 3) Sustained release carriers in the biomedical field, controlling the drug release rate by regulating the crystallinity of AKD.

Compared with similar chemicals, the primary advantage of Alkyl Ketene Dimer lies in its environmental characteristics. The product does not release restricted substances such as formaldehyde and APEO throughout its life cycle, and the VOC content is less than 50ppm. Under the EU CLP regulations, AKD is classified as a non-hazardous chemical, and the transportation and storage costs are about 40% lower than those of fluorinated compounds. A comparison by a third-party testing agency shows that the carbon footprint of the Alkyl Ketene Dimer production process (3.2kg CO₂/kg) is only 1/3 of that of silicone waterproofing agents.

In terms of reaction efficiency, the β-ketoester group of Alkyl Ketene Dimer has high reactivity and can effectively bond to the substrate in the pH range of 6-9, and its applicability far exceeds that of silicone systems that require strong acid conditions. Experimental data show that the theoretical reaction rate constant (k) of AKD and cellulose is 2.3×10⁻³ L/mol·s, which is 1.8 times faster than traditional ASA (alkyl succinic anhydride). In industrial practice, the curing time of Alkyl Ketene Dimer sizing can be shortened to 24 hours, and the turnover efficiency of the production line can be increased by 15%-20%.

The versatility of Alkyl Ketene Dimer is reflected in the fact that Alkyl Ketene Dimer can achieve performance customization through the regulation of alkyl chain length (C16-C22). Long-chain AKD (C18-C22) is more suitable for scenarios with high hydrophobicity requirements, while short-chain products (C14-C16) perform well in coatings with high flexibility requirements. The patented technology of a German specialty chemical company can also introduce epoxy groups into AKD molecules, making it both hydrophobic and adhesive, and successfully applied to the interface enhancement of automotive interior composite materials.

In terms of thermal stability, Alkyl Ketene Dimer remains chemically inert below 180°C, which makes it resistant to most polymer processing temperatures. In the production of polypropylene spunbond nonwovens, the melt flow index (MFI) of the added AKD fluctuates by less than 5%, and the fiber breaking strength increases by 12%. Comparative tests show that the contact angle of PET film modified by Alkyl Ketene Dimer only decreases by 2° after aging for 1000 hours at 150°C, while that of silicone-modified products decreases by 15°.

The economic advantage is reflected in the cost control of the entire process. Although the unit price of Alkyl Ketene Dimer (about US$4.5/kg) is slightly higher than that of rosin sizing agent, its dosage is only 1/2-1/3 of the latter, and the overall cost is reduced by 18%-25%. In the field of textile finishing, the concentration of AKD working fluid can be as low as 0.5%, saving 30% of chemical consumption compared with fluorine-containing finishing agents.

With the growing global demand for sustainable materials, Alkyl Ketene Dimer is moving from a niche field to the mainstream market with its advantages such as biodegradability, multi-scenario applicability and high cost-effectiveness. Future technological breakthroughs may focus on the development of low-temperature curing systems and functionalized molecular design to further expand its application boundaries in cutting-edge fields such as new energy and flexible electronics.

Contact Us

Product Package picture:

Related References:

chemicalbook-Alkyl Ketene Dimer

Wikipedia-Alkyl Ketene Dimer

Alkyl Ketene Dimer Manufacturer

Contact Us

As an experienced Alkyl Ketene Dimer manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Alkyl Ketene Dimer CAS 144245-85-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.