4,4'-Methylenedianiline CAS 101-77-9

Factory wholesale 4,4'-Methylenedianiline CAS 101-77-9

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: 4,4'-Methylenedianiline

CAS: 101-77-9

MOQ: 1KG

Directory Guidance on 4,4'-Methylenedianiline

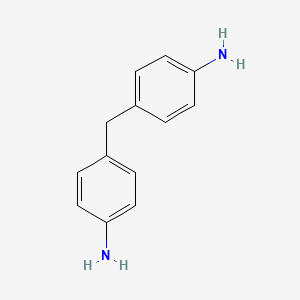

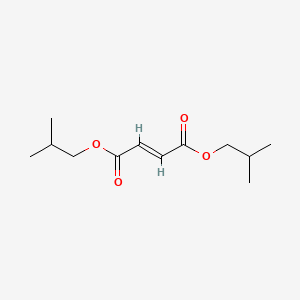

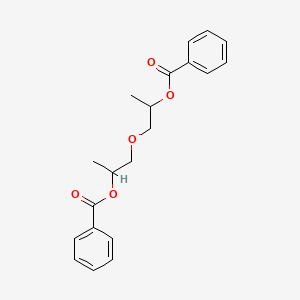

Chemical Structure

Basic Info:

| Melting Point | 89-91 °C(lit.) |

| Boiling Point | 242 °C2 mm Hg(lit.) |

| Density | 1.15 |

| Vapor Pressure | 0Pa at 25℃ |

| Refractive Index | 1.5014 (estimate) |

4,4'-Methylenedianiline Introduction:

4,4′-Methylenedianiline (MDA for short) is an important aromatic diamine compound with a molecular formula of C₁₃H₁₄N₂ and a CAS number of 101-77-9. As a white to light yellow crystalline powder, MDA has a melting point of about 89-91°C and a boiling point of about 398°C. It is slightly soluble in water, but easily soluble in organic solvents such as ethanol, acetone and chloroform.

Industrially synthesizing 4,4′- Methylenedianiline typically involves the condensation reaction between aniline and formaldehyde under acidic catalyst conditions such as hydrochloric or sulfuric acid catalysts; subsequent purification by crystallization or distillation allows production of high purity products.

4,4′-Methylenedianiline has excellent chemical stability; however, it may decompose at higher temperatures or when exposed to strong oxidants and release toxic gases. Due to the two amino groups found within its molecules being highly nucleophilic and reacting with isocyanate groups and epoxy groups readily, 4,4′-Methylenedianiline plays an integral part in polymer materials synthesis; however its toxicological properties should be treated with caution since prolonged exposure could potentially damage livers and kidneys over time; safe operating specifications must also be strictly observed during industrial applications.

From a chemical properties viewpoint, 4,4′-Methylenedianiline exhibits excellent balance in terms of amino reactivity and steric hindrance effect; this allows it not only to ensure efficient reaction rates but also form stable cross-link structures within polymer chains which pave the way for widespread application in materials science applications.

From an industrial development perspective, 4,4′-Methylenedianiline production began in the middle of the 20th century. Demand has surged due to growth of polyurethane and epoxy resin industries worldwide; consequently its global production capacity can currently be found across Asia, Europe and North America, with China becoming one of the main producers and consumers.

Technically, modern production processes have substantially increased both yield and purity of products by optimizing catalyst systems, reaction temperatures, purification processes and by-product generation, while simultaneously decreasing by-product generation. Research into more eco-friendly synthetic routes for MDA production continues apace as well, such as using ionic liquids or immobilized catalysts to minimize wastewater discharge.

Nature and Specifications:

| Item | Specification |

| Product Name | 4,4′-Methylenedianiline |

| CAS No. | 101-77-9 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 430 °F |

| Solubility | water: soluble |

| Pka | 5.32±0.25(Predicted) |

| Color | White to Light yellow |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of 4,4'-Methylenedianiline

In the field of polyurethane, 4,4′-Methylenedianiline plays an indispensable role. Polyurethane materials are widely used in many industries such as footwear, furniture, automotive interiors, and building insulation materials due to their excellent wear resistance, elasticity, and low temperature resistance. When it reacts with isocyanates, it can produce products such as polyurethane foam, elastomers, and adhesives with good performance.

In terms of epoxy resin curing agents, 4,4′-Methylenedianiline also performs very well. Epoxy resin has good mechanical properties, electrical properties, and chemical stability, but a curing agent is required to cure it to form a material with practical value. When it is added to epoxy resin as a curing agent, it can promote the cross-linking curing reaction of epoxy resin to form a three-dimensional network structure. Cured epoxy resin materials can be used for the encapsulation of electronic and electrical products, such as the encapsulation of electronic components such as mobile phones and computers, which can effectively protect internal components from the influence of the external environment; when used in floor coatings, the floor can have high hardness, wear resistance, corrosion resistance and other characteristics, and is suitable for the coating of floors such as factory workshops and parking lots.

In the field of adhesives and sealants, 4,4′-Methylenedianiline is also one of the key raw materials. The adhesives it participates in synthesizing can be used for bonding various materials such as metals, plastics and glass, and have the advantages of high bonding strength, good temperature resistance and resistance to medium corrosion. In industries such as aerospace, automotive manufacturing, and electronic equipment assembly, these high-performance adhesives play a crucial role in connection and sealing, ensuring the integrity and reliability of product structures. For instance, they can be found in key areas such as the bonding of aircraft fuselage structural components and the sealing of automotive windshields.

In the production of rubber products, 4,4 ‘- Methylenedianiline is also actively involved. By blending modification with rubber or acting as an accelerator for vulcanization reactions, the processability and usability of rubber can be improved. For example, improving the tensile strength, wear resistance, and aging resistance of rubber makes rubber products such as tires, hoses, tapes, etc. more durable and reliable in practical use, extending their service life.

In addition, 4,4′-Methylenedianiline is also used as an important raw material or starting material in the synthesis of some special chemical intermediates. It can participate in the synthesis of some compounds with specific functions, which are used in the fields of medicine, pesticides, etc., providing basic material support for the research and development and production of related products, further expanding its application range in the chemical industry.

The Advantages Of 4,4'-Methylenedianiline

From the perspective of chemical properties, 4,4′-Methylenedianiline has good reactivity. Its two amino groups can react with a variety of chemical reagents with fast reaction speed and high conversion rate. When synthesizing various polymer materials and chemicals, it can quickly and effectively participate in the reaction to construct the structure of the target product, thereby improving production efficiency and reducing production costs.This gives it a unique competitive advantage among numerous chemical raw materials and performs well in meeting different reaction requirements.

In terms of product performance, the comprehensive material performance brought by 4,4′-Methylenedianiline is excellent. The polymer materials synthesized based on it, such as polyurethane materials, not only have good mechanical strength, such as high tensile strength, good elastic modulus, etc., but also have excellent wear resistance and can withstand long-term friction and wear; at the same time, its low temperature resistance allows the material to maintain a certain flexibility and elasticity in a low temperature environment, and will not have brittle cracks and other phenomena. For epoxy resin curing systems, it gives the cured material good chemical corrosion resistance, can resist the erosion of chemicals such as acids, alkalis, and salts, prolongs the service life of the material, and enables it to work stably under harsh chemical environment conditions.

In terms of compatibility with other materials, 4,4′-Methylenedianiline also performs well. It can be well compatible with a variety of polymer matrices such as resins, rubbers, and other additives to form a uniform mixed system. This is conducive to the preparation of products with uniform and stable performance during the production process, avoiding defects such as material stratification, cracking, and uneven performance caused by compatibility problems. For example, in the adhesive formula, it has good compatibility with components such as resins and fillers, which makes the adhesive have good construction performance and bonding performance.

From the perspective of production and processing, 4,4′-Methylenedianiline has convenient processing performance. In actual chemical production, it has good solubility and can be dissolved in common organic solvents, which is convenient for mixing with other raw materials; during the reaction process, its reaction conditions are relatively mild, and it is easy to control the temperature, pressure and time of the reaction. The parameters, such as the temperature, pressure and time of the reaction, reduce the requirements for production equipment and the difficulty of production operations to a certain extent, which is conducive to large-scale industrial production.

In addition, from the perspective of safety and environmental protection, the toxicity of 4,4′-Methylenedianiline is relatively low, and it has little health hazards to operators during normal use and processing. At the same time, if it is operated in accordance with the standardized environmental protection requirements during production, use and waste treatment, the impact on the environment is also within an acceptable range. This meets the strict requirements of the contemporary chemical industry for product safety and environmental protection, making it more competitive in the market and able to meet the high standards of various industries for raw material safety and environmental protection.

Contact Us

Product Package picture:

Related References:

chemicalbook-4,4′-Methylenedianiline

4,4'-Methylenedianiline Manufacturer

Contact Us

As an experienced 4,4′-Methylenedianiline manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As 4,4′-Methylenedianiline CAS 101-77-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.