1,3-Butanediol CAS 107-88-0

Factory wholesale 1,3-Butanediol CAS 107-88-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: 1,3-Butanediol

CAS: 107-88-0

MOQ: 1KG

Directory Guidance on 1,3-Butanediol

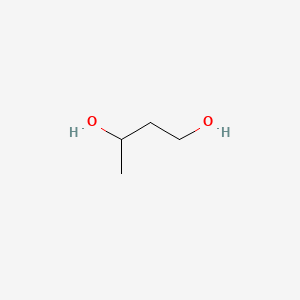

Chemical Structure

Basic Info:

| Melting Point | -54 °C |

| Boiling Point | 203-204 °C(lit.) |

| Density | 1.005 g/mL at 25 °C(lit.) |

| Vapor Density | 3.1 (20 °C, vs air) |

1,3-Butanediol Introduction:

1, 3-butanediol, with the chemical formula C4H10O2, is often abbreviated as 1,3-BDO. It is a straight-chain aliphatic diol composed of four carbon atoms, with two hydroxyl groups (-OH) located at the end of the chain (carbon 1) and the third carbon atom in the chain, respectively. It appears as a colorless, viscous, slightly hygroscopic clear liquid at normal temperature and pressure, with a slightly sweet syrup-like odor.

Compared with common diols such as ethylene glycol and propylene glycol, 1,3-Butanediol has a slightly higher viscosity. However, its longer carbon chain also endows it with some unique property combinations, making it of significant value in multiple industrial and technological fields. From a chemical structure perspective, it belongs to primary and secondary diols (that is, one hydroxyl group is attached to the primary carbon and the other to the secondary carbon), which to some extent affects its reactivity and application direction.

This compound was initially mainly produced on a large scale through chemical synthesis, mainly through the aldol condensation reaction of acetaldehyde under alkaline conditions to form 3-hydroxybutyraldehyde, and then further hydrogenation reduction to obtain 1, 3-butanediol. This classic synthetic path is relatively mature in industry and can stably provide products.

With the rapid development of biotechnology, the production of this product through microbial fermentation using renewable biomass resources (such as sugars, starches, cellulose, etc.) has become a highly promising research direction and has been adopted by some leading enterprises. The production of bio-based 1,3-Butanediol mainly relies on specific microbial strains, such as engineered Escherichia coli or Klebsiella, which can efficiently convert sugar into the target product under optimized fermentation conditions. This conforms to the current global trend of pursuing sustainable development and green chemistry.

In terms of physical and chemical properties, 1,3-Butanediol exhibits excellent solubility. It can be miscible with water, alcohols, ethers, ketones, esters, and many low-molecular-weight organic solvents in any proportion. This outstanding solubility is the physical basis for its wide application. However, it has poor solubility for non-polar aliphatic hydrocarbon solvents. It has a relatively high boiling point (about 207-208°C) and a relatively low melting point (less than -50°C), and has a wide range of liquid operating temperatures at room temperature. The flash point is approximately 121°C (closed cup), and it is a flammable liquid, but its danger is relatively lower than that of low-boiling-point alcohols.

Nature and Specifications:

| Item | Specification |

| Product Name | 1,3-Butanediol |

| CAS No. | 107-88-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 250 °F |

| Storage Temp. | Store below +30°C. |

| Solubility | >500g/lMiscible |

| Form | Liquid |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of 1,3-Butanediol

In the cosmetics and personal care industry, 1,3-Butanediol plays an indispensable role. As a wetting agent and moisturizer, it has a moisturizing ability similar to glycerin, but it has a lower stickiness and a more refreshing and smooth skin feel. It is particularly suitable for use in essences, lotions, creams, masks and hair care products to enhance the user experience.

It is also a solvent and coupling agent, which can effectively dissolve a variety of water-soluble or oil-soluble active ingredients, fragrances and organic sunscreens (such as avobenzone), ensuring that the formula is stable and uniform, and avoiding precipitation or stratification. Its good penetration-promoting properties can enhance the ability of certain active ingredients (such as whitening agents and vitamin derivatives) to penetrate the stratum corneum and improve efficacy.

In the pharmaceutical industry, the application value of 1,3-Butanediol is also becoming increasingly prominent. It is an important synthetic building block for the preparation of a variety of pharmaceutical intermediates and APIs. For example, in the synthesis of certain cardiovascular drugs, sedatives and other biologically active molecules, the alcohol hydroxyl group of 1,3-Butanediol or its activated form can be used as a key reaction site.

As a solvent and carrier, it is used to extract plant active ingredients, prepare topical preparations (such as gels, lotions) and certain oral liquid preparations. Its excellent solubility and low skin irritation make it potential for application in transdermal drug delivery systems. In addition, it can also be used as a stabilizer for liquid drug preparations to help prevent hydrolysis or oxidation of certain ingredients.

In the field of industrial chemicals and polymer synthesis, 1,3-Butanediol is one of the key chemical intermediates. It can be used to prepare the important monomer 1,3-butanediol diglycidyl ether (BDDE), which is an important crosslinker and reactive diluent for the synthesis of epoxy resins, and is ultimately used in high-performance composites, adhesives, and coatings.

The hydroxyl groups in its molecules are subjected to esterification reactions to produce monomers such as 1,3-Butanediol diacrylate, dimethacrylate or diacetate, which are often used in radiation-cured materials (such as UV-cured inks, coatings), polymer modifiers or plasticizers. Through the oxidation reaction path, 1,3-Butanediol is also an important precursor for the preparation of chemicals such as acetylacetone and diacetyl (margarine flavoring agent).

As an industrial solvent, 1,3-Butanediol plays a role in special scenarios due to its high boiling point, low volatility, good thermal stability and excellent solubility. It is used in printing inks (especially some special ink systems), special coatings, electronic chemical cleaning and as a high-boiling reaction medium, especially in processes that require long-term heating or gentle evaporation.

Although cost factors limit its application in large-area cleaning replacement, its low volatility is an advantage for some precision cleaning occasions and areas with demanding requirements for solvent residues. In the emerging field of e-cigarette oil, due to its hygroscopicity, ability to dissolve nicotine and other flavors, low potential toxicity and the ability to produce sufficient smoke, it is often used as the main carrier (solvent) of e-cigarette oil and is used in combination with other polyols such as propylene glycol to optimize the experience.

In addition, in the food industry, 1,3-Butanediol is allowed to be used as a food flavor or extraction solvent in a very limited range by regulations in some countries or regions due to its low toxicity. It should be emphasized that its use in food is subject to extremely strict regulatory restrictions and is not a common phenomenon.

In the polyurethane industry, although 1,4-butanediol (BDO) dominates the synthesis of polyester polyols, 1,3-Butanediol also has room for exploration in the synthesis of polyester polyols with specific properties (such as flexibility and crystallinity) due to its chain structure differences. In the field of biodegradable plastics, the main raw material of polybutylene succinate (PBS) is 1,4-butanediol, but some studies have also explored the possibility of introducing 1,3-Butanediol to improve material properties. It has also been reported as a component of a deicer (using its hygroscopicity to lower the freezing point).

The Advantages Of 1,3-Butanediol

In terms of thermal stability, its thermal decomposition temperature is higher than its boiling point (usually above 250°C). It shows good inertness in the conventional processing temperature range and is not easy to decompose, discolor, or produce undesirable products, which is crucial to ensure product quality.

It has a significant effect on solubilizing active ingredients and flavors. This unique combination of solubility properties is sometimes difficult to replace by a single solvent. At the same time, 1,3-Butanediol also has a certain solubility or swelling ability for a variety of resins (such as certain acrylates, phenolic resins) or polymers (such as polyvinyl alcohol), which provides a basis for its application in adhesives, coatings and other fields.

Safety is the most differentiated and outstanding advantage of 1,3-Butanediol. A large number of toxicological studies have shown that it exhibits an excellent biosafety spectrum, whether it is acute toxicity (high LD50 value), chronic toxicity, sensitization or mutagenicity. Its high flash point (>121°C) also provides it with a high fire safety level during transportation, storage and use.

Its toxicity and irritation are much lower than those of common propylene glycol or glycerol (under the same usage concentration and conditions), which makes it irreplaceable in products that need to directly contact the skin or even mucous membranes (such as high-end cosmetics, topical drugs, and oral care products).

Compared with some special diols or solvents (such as dipropylene glycol and diethylene glycol), 1,3-Butanediol has obvious cost advantages. Its production process (whether chemical or fermentation method) has been relatively mature after years of optimization, and large-scale industrial production has kept its unit cost within an acceptable range, especially in application scenarios where high performance and high safety requirements cannot be compromised, its cost-effectiveness is reflected.

This cost competitiveness combined with its unique functionality has enabled it to maintain strong vitality in the target market. With the continuous advancement of fermentation process technology and the expansion of demand for bio-based materials, the cost of bio-based 1,3-Butanediol is expected to further decline in the future and occupy a higher market share.

Contact Us

Product Package picture:

Related References:

Chemicalbook-1,3-Butanediol

1,3-Butanediol Manufacturer

Contact Us

As an experienced Titanium Tetrachloride manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Titanium Tetrachloride CAS 107-88-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.