Sodium Chlorite CAS 7758-19-2

Factory wholesale Sodium Chlorite CAS 7758-19-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Sodium Chlorite

CAS: 7758-19-2

MOQ: 1KG

Directory Guidance on Sodium Chlorite

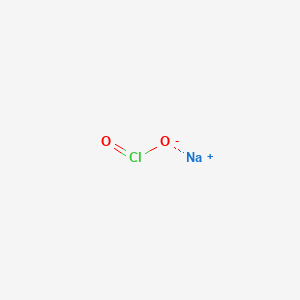

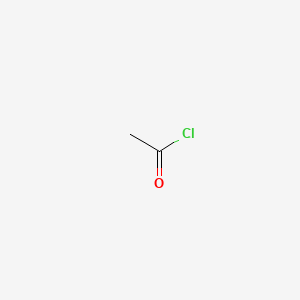

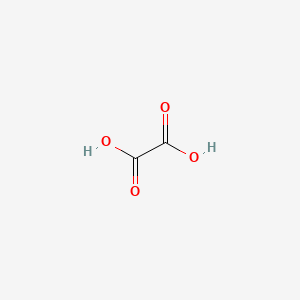

Chemical Structure

Basic Info:

| Melting Point | 190 °C (dec.) |

| Boiling Point | ≥100°C/1013hPa |

| Density | 2.5 g/cm3 |

| Vapor Pressure | 0Pa at 25℃ |

Sodium Chlorite Introduction:

Similar to most chlorites, the solid form of Sodium Chlorite is usually relatively stable. However, its solution system has strong chemical activity. Its most core chemical property stems from the strong REDOX capacity contained in the chlorite ion (ClO₂⁻), with a REDOX potential as high as approximately +0.76V (even approaching +1.3V under acidic conditions), which endows it with outstanding performance in efficiently oxidizing and decomposing various organic pollutants and eliminating microorganisms.

In terms of physical and chemical properties, solid Sodium Chlorite presents a typical crystal structure, with a melting point range of approximately 180-200℃, and begins to decompose significantly at this temperature. Its aqueous solution is alkaline (the pH value is usually maintained at 8 to 10), and the solution color varies from colorless to yellowish green depending on the concentration. It is particularly worth noting the thermal stability sensitivity of Sodium Chlorite: when heated, impacted or in contact with specific reducing substances, the solid or high-concentration solution has the potential risk of decomposition or even explosion.

In terms of safety requirements, great importance must be attached to the potential risks during the use and storage of Sodium Chlorite. Solids should be stored in a cool, dry and well-ventilated place, and strictly kept away from organic reducing materials (such as wood chips, oils), strong acids and heat sources. When preparing the solution, non-metallic containers should be used and it should be ensured that the preparation area has good ventilation. Operators should wear necessary personal protective equipment (protective goggles, gloves, respiratory protective equipment) and be clearly aware that acidic activation is the main source of risk.

When a leakage occurs, it is essential to handle it in accordance with the hazardous chemical leakage plan to avoid contact with acidic substances that may cause violent reactions and the release of ClO₂ gas. In case of accidental contact with skin or eyes, rinse continuously with plenty of running water. In case of inhalation of gas or accidental ingestion, seek professional medical assistance immediately. A profound understanding and effective prevention of the potential hazards caused by its inherent oxidative activation process is the core prerequisite for ensuring its safe application.

Nature and Specifications:

| Item | Specification |

| Product Name | Sodium Chlorite |

| CAS No. | 7758-19-2 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Form | Powder |

| Color | White |

| Odor | odorless |

| PH Range | 10 – 11 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Sodium Chlorite

Sodium Chlorite and the chlorine dioxide produced after activation have been widely used as key chemicals in the bleaching process of various types of paper, pulp and textiles due to their strong oxidation and killing capabilities. Compared with traditional chlorine-containing bleaching agents (such as chlorine gas and sodium hypochlorite), the damage to cellulose by the oxidation process of Sodium Chlorite or ClO₂ is significantly reduced, which helps to maintain the mechanical strength and gloss of the product.

More importantly, Sodium Chlorite can more effectively break up the chromophores when oxidizing colored impurities such as lignin without forming highly toxic adsorbable organic halides (AOX), so it occupies a core position in modern environmentally friendly chlorine-free bleaching (ECF) processes. Even in difficult bleaching scenarios (such as some specialty papers or high whiteness requirements), it is often used as an important supplementary chemical in the strengthening stage. At the same time, it is also used in fading treatment in the printing and dyeing industry.

In the food production chain, disinfection solutions based on Sodium Chlorite have the advantages of high efficiency and broad spectrum antibacterial (including resistance to heat-resistant spores) and significant removal of pesticide residues and fungal toxin contamination, while not affecting the appearance, color and flavor of food.

Therefore, it is widely used in the strong online sterilization of food processing lines (equipment, pipelines, ambient air, packaging materials), the core ingredients of fruit and vegetable post-harvest preservative formulas, the biological contamination control of seafood processing lines, and the pre-cooling and disinfection process of meat/poultry carcasses. Especially when there is a threat of heat-resistant microorganisms, the high gaseous permeability and low residual toxicity of ClO₂ gas make it almost irreplaceable in this field.

The medical and public health fields also need to rely on its powerful disinfection effect. Medical equipment, especially precision instruments (such as endoscopes) that have strict requirements for disinfection conditions, require a mild, efficient and low-corrosive disinfection method for materials. ClO₂ solution (prepared by activation with Sodium Chlorite) is one of the ideal choices to meet this demand.

In addition, hospital environmental disinfection, laboratory biosafety cabinet disinfection, and even environmental control in biopharmaceutical-related areas often utilize the strong penetration and strong killing advantages of ClO₂ gas. For the special needs of highly infectious pathogen-contaminated areas (such as the disinfection of highly pathogenic pathogens such as Ebola), the adjustable release of ClO₂ gas disinfection technology has unique technical value. In public health emergency treatment (such as rapid disinfection of contaminated water bodies and post-disaster environments), ClO₂ has also become one of the preferred technologies due to its rapid effectiveness and broad spectrum.

In addition, the oxidation capacity of Sodium Chlorite and ClO₂ extends to more sub-sectors. In industrial flue gas desulfurization and denitrification technology, ClO₂, as a highly selective oxidant, can efficiently oxidize the water-insoluble NO in the flue gas into highly water-soluble NO₂ or nitrates, thereby greatly improving the combined removal efficiency of pollutants by subsequent absorbents (such as lime milk) (such as synergistic desulfurization and denitrification processes). It is also used for catalytic leaching or preferential oxidation and decomposition of impurities in some hydrometallurgical processes or precious metal recovery processes.

In the manufacturing of precision electronic components or high-end optical components, extremely low concentration ClO₂ solution becomes a component of ultra-clean processing liquid in key processes due to its excellent oxidation cleaning ability and low metal ion residue (compared with peroxide). Although facing competitive challenges from other chemicals in terms of cost or ease of use, Sodium Chlorite/ClO₂’s core competitiveness based on technical performance in complex technical scenarios is still significant.

The Advantages Of Sodium Chlorite

In terms of reaction performance and efficiency, Sodium Chlorite exhibits strong oxidizing power. The ClO₂ produced by activation has an efficient electron transfer capacity of up to +1.5 electron equivalents (under acidic conditions), and its oxidizing capacity far exceeds that of conventional chlorine disinfectants (e.g., chlorine gas only has +1 effective equivalent out of +2 electron equivalents, and the actual effective value of sodium hypochlorite is about +2 equivalents). This means that at equimolar usage, it can destroy the structure of the target pollutant more quickly and thoroughly.

In terms of safety and environmental friendliness, although the raw material of Sodium Chlorite itself needs to be carefully controlled, its core advantage lies in the fact that the terminal active product ClO₂ used for oxidative disinfection is mainly reduced to generate a byproduct that is relatively benign to the ecological environment – chloride ions (Cl⁻). Compared with the complex chemical chain reaction of byproducts of chlorine disinfection in the presence of organic matter, the chemical behavior of ClO₂ is greatly simplified. This not only significantly reduces the long-term health exposure risk of drinking water, but also fundamentally alleviates the pressure of ecotoxicological supervision faced by the discharge of salt-containing wastewater.

From the perspective of economy and wide adaptability, Sodium Chlorite and the ClO₂ gas generated by its activation have extremely high oxidation efficiency per unit mass. Especially when dealing with highly resistant pathogenic microorganisms (such as Cryptosporidium oocysts, Giardia cysts) or highly refractory organic pollutants (such as phenols, anilines, specific pharmaceutical intermediates, and some pesticides), the removal depth that can be achieved with the same dosage is often better than many other mainstream oxidation technologies (such as ozone, hydrogen peroxide, and single advanced oxidation processes).

Contact Us

Product Package picture:

Related References:

Chemicalbook-Sodium Chlorite

Sodium Chlorite Manufacturer

Contact Us

As an experienced Sodium Chlorite manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Sodium Chlorite CAS 7758-19-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.