Sodium Stearate CAS 822-16-2

Factory wholesale Sodium Stearate CAS 822-16-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Sodium Stearate

CAS: 822-16-2

MOQ: 1KG

Directory Guidance on Sodium Stearate

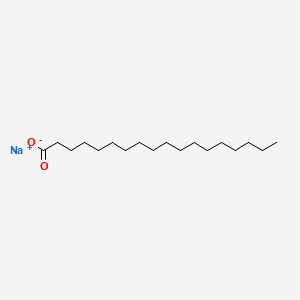

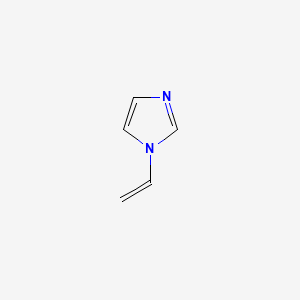

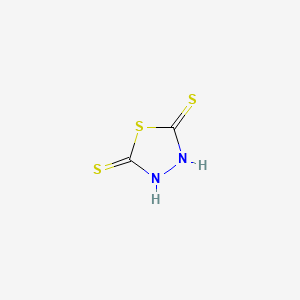

Chemical Structure

Basic Info:

| Melting Point | 270 °C |

| Density | 1.07 g/cm3 |

| Storage Temp. | 2-8°C |

| Solubility | Slightly soluble in water and in ethanol (96 per cent). |

Sodium Stearate Introduction:

Sodium Stearate, an indispensable chemical substance used widely across industries and daily life, has become an integral component in many fields with its diverse applications and properties. Composed of C18H35COONa composed of C18H35COO- and Na+ ions (stearate ions are C18H35COONa), this unique chemical structure confers both physical and chemical characteristics making it well soluble in aqueous solutions and surface activity properties.

At room temperature and pressure, Sodium Stearate usually appears as a white or light yellow powder, flake or block solid with a greasy feel. This tactile feature is closely related to its chemical structure. Its long carbon chain structure makes the intermolecular force relatively special, thus showing a unique texture in physical form.

The preparation process of Sodium Stearate is relatively mature and diversified. Common production methods mainly include chemical synthesis and biosynthesis. Chemical synthesis is the mainstream process in industrial production at present, and the product is mainly produced by neutralization reaction of fatty acids and sodium hydroxide.

Biosynthesis is an emerging preparation method, which mainly uses microbial fermentation technology to metabolize raw materials containing fatty acid precursors through specific microorganisms to produce Sodium Stearate. The advantage of this method is that the raw materials are widely available and renewable, which conforms to the concept of sustainable development. At the same time, there are fewer by-products produced during the production process, and the impact on the environment is relatively small.

Sodium Stearate has many advantages for both safety and environmental protection. Being biodegradable, it can be broken down by microorganisms in its natural environment and will not create pollution over time. Furthermore, toxicological studies have confirmed its low acute toxicity to mammals as well as no signs of skin contact irritation or inhalation toxicity, making Sodium Stearate suitable for use in daily chemicals, food and other fields of industry.

Nature and Specifications:

| Item | Specification |

| Product Name | Sodium Stearate |

| CAS No. | 822-16-2 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Form | Powder |

| Color | white |

| Odor | wh. fine powd., fatty (tallow) odor |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Sodium Stearate

In the daily chemical industry, the application of Sodium Stealate covers almost all cleaning and care product systems. As the main component of soap, its emulsifying effect can effectively remove oil from the skin surface, and the formed micelle structure can wrap around dirt particles to achieve stain removal.In cosmetic formulations, it can be used as a thickener for cream products to improve the viscosity and stability of the products, and can also improve the spreadability of the emulsion by adjusting the surface tension.

In the skincare category, the synergistic effect of Sodium Stealate and moisturizing agents such as glycerin can form a protective film layer, reducing water evaporation. In shampoo products, the balance between foaming performance and degreasing power is highly favored by formulators, which can ensure the cleaning effect while avoiding hair damage caused by excessive degreasing.

Sodium Stearate’s demand in plastic and rubber industries continues to increase due to its multifunctionality in polymer processing. When producing PVC products, as an internal lubricant it can reduce viscosity of the melt and improve material flowability while as an external lubricant it reduces adhesion between the melt and metal surfaces of equipment.

In the pharmaceutical industry, Sodium Stealate’s excipient grade products meet USP/EP standards and are widely used as part of tablet and capsule molding processes. When used as a lubricant between powder and die, improving tablet pressing efficiency, and reducing equipment wear; in sustained-release formulations it acts to regulate dissolution rates with long-lasting release effects.

In topical preparations such as ointments, their emulsifying stabilizing effect can maintain a uniform distribution of oil and water phases, ensuring the uniform release of effective ingredients. It is worth noting that the application of Sodium Stealate in the pharmaceutical field requires strict control of heavy metals and microbial limits, which puts higher demands on its production process.

Innovative applications in the construction industry are expanding the market space for Sodium Stearate. In cement-based materials, its hydrophobic modification can significantly reduce capillary water absorption and improve the freeze-thaw resistance and corrosion resistance of concrete. Adding an appropriate amount of this product to gypsum products can not only improve the fluidity of the slurry for easy molding, but also form a hydrophobic surface after hardening.

In the field of waterproof coatings, its synergistic effect with organic silicon materials can construct a multi-layer protective system that maintains breathability while blocking the penetration of liquid water. In addition, in the segmented fields of ceramic body reinforcement agents, asphalt modifiers, etc., Sodium Stealate has also demonstrated unique performance advantages.

The Advantages Of Sodium Stearate

Under high temperature conditions, the thermal stability of Sodium Stearate is significantly better than that of most organic surfactants, and it will not decompose significantly below 180°C, which is particularly important for the plastic and rubber industries that require high-temperature processing. Compared with similar products such as calcium stearate, the sodium salt has better water solubility and is irreplaceable in areas that require aqueous phase dispersion.

In terms of application performance, Sodium Stearate exhibits excellent compatibility synergistic effects. When compounded with anionic surfactants, it can enhance the emulsification stability of the system; when used in combination with nonionic surfactants, it can significantly improve low-temperature solubility. In polymer processing, its synergistic lubrication effect with metal soaps such as zinc stearate and magnesium stearate increases processing efficiency by more than 23% compared to a single additive. This good synergy not only expands the scope of application, but also enables formulators to accurately control product performance by adjusting the proportion.

The wide range of raw material sources constitutes the cost advantage of Sodium Stearate. The production route using natural oils as raw materials not only conforms to the environmental protection trend of renewable resource utilization, but also avoids market volatility risks through the strategy of raw material diversification. The advancement of modern separation and purification technology makes it possible to extract stearic acid from mixed fatty acids with high selectivity, which significantly improves resource utilization.

From the perspective of production process, the application of continuous saponification reactor reduces the energy consumption of traditional intermittent production by more than 40%, and the mother liquor circulation technology increases the glycerol recovery rate to 98%. These technological innovations continue to strengthen its cost competitiveness.

The cost-effectiveness advantage is the key factor for Sodium Stearate to continue to occupy the market. Although the price per unit mass is higher than that of some synthetic surfactants, its addition amount in the formula is usually only 0.5%-2% to achieve the expected effect, and the full life cycle cost is more advantageous.This high consistency meets the stringent requirements for batch-to-batch control of raw materials in the field of high-end manufacturing.

Environmental properties are the key advantage of Sodium Stearate compared to synthetic surfactants. Its fully biodegradable properties meet the increasingly stringent environmental regulations worldwide, and are listed as low-risk substances in the EU REACH regulations, China’s new chemical substance environmental management methods and other systems. At the toxicological level, the LD50 value of Sodium Stearate (rat oral) is greater than 5000 mg/kg, which is a practically non-toxic substance, which clears the regulatory barriers for its application in sensitive areas such as food contact materials and children’s products. From the perspective of life cycle assessment, the carbon footprint of its production process is 62% lower than that of petroleum-based surfactants, which is more competitive in the context of the gradual establishment of an international carbon tariff system.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Sodium Stearate

Sodium Stearate Manufacturer

Contact Us

As an experienced Sodium Stearate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Sodium Stearate CAS 822-16-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.