Diisooctyl Azelaate CAS 26544-17-2

Factory wholesale Diisooctyl Azelaate CAS 26544-17-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diisooctyl Azelaate

CAS: 26544-17-2

MOQ: 1KG

Directory Guidance on Diisooctyl Azelaate

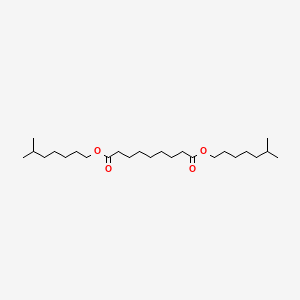

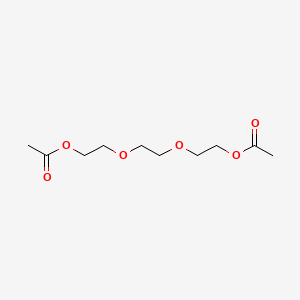

Chemical Structure

Basic Info:

| Melting Point | 55-65 °C |

| Boiling Point | 208-210 °C2 mm Hg(lit.) |

| Density | 0.905 g/mL at 25 °C(lit.) |

| Pour Point | -18 |

Diisooctyl Azelaate Introduction:

Diisooctyl Azelaate, The chemical name is azelodic acid dioctyl ester, which is an important organic chemical raw material. From the perspective of molecular structure, it is generated by esterification reaction between azelaic acid and isooctanol, with a molecular formula of C22H42O4 and a molecular weight of 374.57. Azeoic acid itself is a saturated fatty dicarboxylic acid with two carboxyl groups, and its chemical properties are relatively active. Isooctanol is a common fatty alcohol with good solubility and reactivity. The combination of the two forms Diisooctyl Azelaate, which inherits some of the characteristics of azelaic acid and also has some advantages of isooctanol, and has a unique and important position in the field of chemistry.

In terms of physical properties, Diisooctyl Azelaate is usually in the form of an oily liquid, light in color, and has a certain volatility, but compared with some low molecular weight organic solvents, its volatilization rate is relatively slow, which makes it relatively stable in a variety of application scenarios. It can remain liquid at room temperature, which is convenient for mixing and processing with other substances. In terms of solubility, This good solubility provides convenience for its application in different formulation systems.

In terms of chemical properties, Diisooctyl Azelaate has certain chemical stability and is not easy to decompose at room temperature and pressure, but can participate in transesterification and saponification under specific chemical reaction conditions. For example, in the transesterification reaction, it can exchange with some other ester substances under the action of a catalyst to generate new ester compounds; in the saponification reaction, when encountering a strong base, it will hydrolyze to generate azelaic acid salt and isooctyl alcohol. These chemical properties make Diisooctyl Azelaate have potential application value in chemical synthesis, surfactant preparation and other fields.

The development history of diisooctyl azelaate in the chemical industry can be traced back to the middle of the 20th century. With the development of the organic chemical industry and the increasing demand for various fine chemicals, its production technology and application fields have gradually been expanded and improved. In the early days, it was mainly used as a raw material for plasticizers in the plastic processing industry. With the in-depth research on its properties, its application advantages in cosmetics, coatings, synthetic rubber and other fields have gradually been discovered, and it has become a basic chemical raw material widely used in many industries.

Nature and Specifications:

| Item | Specification |

| Product Name | Diisooctyl Azelaate |

| CAS No. | 26544-17-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Refractive Index | n20/D 1.451(lit.) |

| Fp | >230 °F |

| Form | Liquid |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Diisooctyl Azelaate

Diisooctyl Azelaate has a wide range of applications in the industrial field, especially occupying an important position in the plastic processing industry. As a high-performance plasticizer, it can significantly improve the flexibility, cold resistance, heat resistance, and weather resistance of plastic products.

In the production of polyvinyl chloride (PVC) products, adding an appropriate amount of Diisooctyl Azelaate can transform PVC from a hard and brittle material to a soft and elastic product, such as soft PVC pipes, sheets, films, etc. These products are widely used in the construction industry’s water supply and drainage pipes, packaging materials, agricultural cover films, and other fields.

In the fields of automotive coatings, industrial coatings, and furniture coatings, coatings with Diisooctyl Azelaate not only have good appearance effects, but also improve the durability and corrosion resistance of the coating film and extend the service life of the coating. In addition, it can also participate in the curing reaction of the coating, play a certain role in promoting the cross-linking and curing process of the coating, and further improve the performance of the coating film.

In the molding process of rubber products, the presence of Diisooctyl Azelaate can make the rubber have better fluidity and plasticity, which is convenient for extrusion, calendering, molding and other molding operations, thereby producing rubber products with complex shapes and precise dimensions, such as rubber seals, rubber tubes, rubber pads, etc. Moreover, the rubber products modified by it have better flexibility, wear resistance and aging resistance during use, and can meet the performance requirements of different use environments.

The field of lubricants is another important application direction of Diisooctyl Azelaate. As a synthetic ester-based base oil, the long-chain structure in its molecules endows the lubricating oil with excellent viscosity-temperature characteristics and boundary lubrication performance. In high-temperature gear oil and compressor oil, it can effectively reduce the coefficient of friction, decrease equipment wear, and maintain stable oil film strength over a wide temperature range.

Compared with mineral oil, Diisooctyl Azelaate has a higher biodegradability rate and is particularly suitable for the development of environmentally friendly lubricants. In metalworking fluids, it can also serve as an extreme pressure additive, forming a chemical reaction film with the metal surface under high temperature and high pressure conditions to prevent direct contact between metals. This is of great significance for quality control in the precision mechanical processing process.

The Advantages Of Diisooctyl Azelaate

From the perspective of material performance, the core advantage of Diisooctyl Azelaate lies in its balanced physical and chemical properties. Compared with traditional plasticizers, it has the characteristics of low volatility loss and high migration stability. Its vapor pressure (about 1×10⁻⁶ Pa at 20°C) is two orders of magnitude lower than that of phthalates, and there is almost no performance degradation due to volatility during high-temperature processing or long-term use.

At the same time, the molecular weight (about 428 g/mol) and branched structure of Diisooctyl Azelaate effectively inhibit molecular migration. In soft PVC products, after 1000 hours of heat aging test, its mass loss rate does not exceed 0.5%, which is much lower than conventional plasticizers such as DOP. This stability is particularly important for areas such as automotive interiors and medical devices that have strict restrictions on volatile organic compounds (VOCs).

From the perspective of process adaptability, Diisooctyl Azelaate shows excellent processing tolerance. Its plasticizing efficiency with PVC resin (based on DOP as 100%) can reach 95%, and similar hardness and elongation can be obtained at the same addition amount.

For thermoformed products that require secondary processing, Diisooctyl Azelaate has a weak plasticizing memory effect, which is conducive to maintaining the dimensional stability of the product. In addition, it has a significant synergistic effect with additives such as stabilizers and flame retardants, and will not cause precipitation or color changes in complex formulation systems, which is crucial for the development of multifunctional composite materials.

The economic advantage gives Diisooctyl Azelaate a favorable position in market competition. Although its unit price is slightly higher than that of ordinary plasticizers, the comprehensive use cost is more competitive. Taking PVC cable material as an example, its addition amount can be reduced by 10-15% compared with DOP to achieve the same softness, and the product life is extended by more than 30%.

The application of nanocomposite technology has opened up a new direction. It can be combined with layered silicates to prepare nanocomposites with both plasticizing and reinforcing functions. In the field of sustainable chemistry, the research on its synthesis by biocatalysis has entered the pilot stage. The selectivity of the enzymatic reaction exceeds 98%, which greatly reduces energy consumption and achieves atomic economy. These breakthroughs will promote Diisooctyl Azelaate to evolve in a more efficient and environmentally friendly direction.

Environmental compliance is the key factor that makes Diisooctyl Azelaate stand out. As global restrictions on phthalate plasticizers are strengthened (such as the EU RoHS directive and the US CPSC standard), it is an environmentally friendly alternative that is phthalate-free and heavy metal-free, and fully complies with food contact material standards such as FDA 21 CFR 175.300 and EU 10/2011. Its ecotoxicology data shows that the median lethal concentration (LC50) for aquatic organisms is greater than 100 mg/L, and the degradation rate in the OECD 301F biodegradation test is more than 60% in 28 days. These data support its application in environmentally sensitive fields. Especially in the strictly regulated markets such as children’s toys and food packaging, it has become a technical solution to meet regulatory requirements.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Diisooctyl Azelaate

Diisooctyl Azelaate Manufacturer

Contact Us

As an experienced Diisooctyl Azelaate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diisooctyl Azelaate CAS 26544-17-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.