Diisooctyl Phthalate CAS 27554-26-3

Factory wholesale Diisooctyl Phthalate CAS 27554-26-3

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diisooctyl Phthalate

CAS: 27554-26-3

MOQ: 1KG

Directory Guidance on Diisooctyl Phthalate

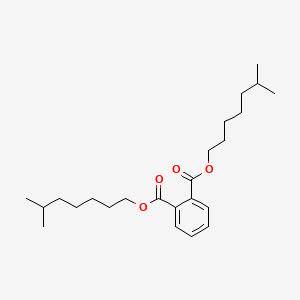

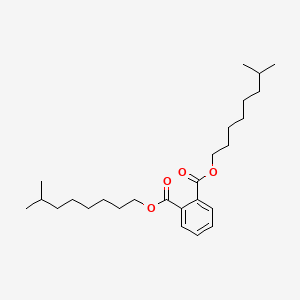

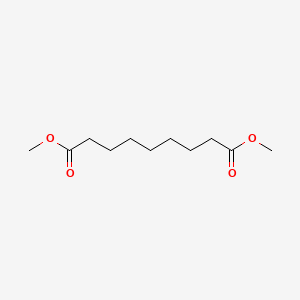

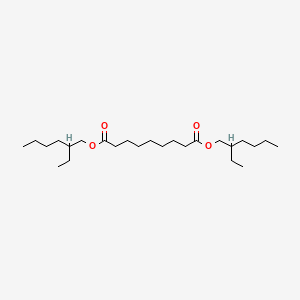

Chemical Structure

Basic Info:

| Melting Point | -4°C |

| Boiling Point | 435.74°C (rough estimate) |

| Density | 0.983 g/mL at 25 °C(lit.) |

| Pour Point | -46 |

| Vapor Pressure | 1 mm Hg ( 200 °C) |

Diisooctyl Phthalate Introduction:

Diisooctyl Phthalate is an essential organic chemical raw material. It plays an integral part in industrial production and has various applications across many fields. Chemically speaking, Diisooctyl Phthalate’s molecular formula is C24H38O4; and its molecular weight approximates to 390.56. Physically speaking, Diisooctyl Phthalate appears as a colorless and transparent viscous liquid with excellent solubility properties; therefore making its use convenient across many application scenarios.

Diisooctyl Phthalate’s physical properties include its density (20), flash point (open), and boiling point, all being around 200. These physical parameters help ensure its safety and stability during processing and use; its boiling point reaches up to 380-400. Furthermore, its refractive index (20) measures at about 1.488 which will come into play in situations requiring material transparency.

Diisooctyl Phthalate belongs to the class of phthalate compounds and features characteristic chemical reaction characteristics of ester compounds, such as hydrolysis under acidic or alkaline conditions to generate phthalic acid and alcohol substances, respectively. Additionally, this compound offers certain redox stability; under typical industrial production and use environments it does not easily undergo oxidation or reduction reactions, thus maintaining performance stability over time.

As one of the largest and most widely used varieties in the phthalate family, Diisooctyl Phthalate is mainly synthesized in industrial production through ester exchange reaction of phthalic anhydride and isooctyl alcohol under the action of acidic catalysts. The process route is mature and the cost is controllable. Despite its large molecular weight, Diisooctyl Phthalate occupies a core position in polyvinyl chloride (PVC) products due to its excellent plasticizing efficiency and compatibility with a variety of polymers, accounting for about 70% of the total global plasticizer consumption.

Nature and Specifications:

| Item | Specification |

| Product Name | Diisooctyl Phthalate |

| CAS No. | 27554-26-3 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Form | Oil |

| Color | Colourless |

| Water Solubility | 40ug/L(25 ºC) |

| LogP | 8.516 (est) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Diisooctyl Phthalate

Diisooctyl Phthalate has long been utilized as the go-to plasticizer in plastic industry production. With long-chain alkyl groups present in its molecular structure, Diisooctyl Phthalate’s long-chain plasticizer molecules can insert between PVC polymer chains to weaken interaction forces between polymers chains while improving flexibility and ductility of materials. This characteristic makes Diisooctyl Phthalate an indispensable ingredient when producing flexible materials like films, cable sheaths or synthetic leather products.

Medical device industry relies heavily on Diisooctyl Phthalate’s plasticizing effect to produce disposable medical consumables like infusion tubes and blood bags made of PVC, such as its transparency and age resistance despite concerns of migration risks. Even so, its technological continuity remains maintained.

Diisooctyl Phthalate can improve adhesion and weather resistance of coatings in coatings and ink industries, while at the same time helping suppress coating cracking in high temperature/humidity environments. Meanwhile, cosmetic companies leverage its low volatility/solubility for nail polish, hair gels and other cosmetics formulas, thus improving texture and performance of their products.

In the electronics and electrical industry, Diisooctyl Phthalate is used to manufacture insulated cables and circuit board packaging materials. Its dielectric constant and volume resistivity can meet the stringent insulation performance requirements of precision electronic components. The automotive industry applies it to the production of interior parts, sealing strips, and other components, balancing vehicle lightweighting and durability requirements by adjusting material hardness and wear resistance.

In the agricultural field, Diisooctyl Phthalate, as a plasticizer for agricultural films, can extend the service life of covering materials and improve their UV resistance. Under environmental pressure, some application scenarios have gradually adopted alternative plasticizers, but Diisooctyl Phthalate’s dominant position in cost sensitive industries is difficult to shake in the short term. This widespread application distribution not only reflects its technological universality, but also reflects the dynamic game between performance requirements and security regulations in the process of industrial upgrading.

Diisooctyl Phthalate also has some applications in other fields. For example, in the cosmetics industry, it can be used as a solvent and thickener for certain cosmetics to improve their texture and stability; In the field of electronic appliances, it can be used to manufacture electronic components and insulation materials with flexibility requirements, ensuring the stability and reliability of electronic devices during use. In addition, in the production of some daily necessities such as raincoats, tablecloths and other PVC products, Diisooctyl Phthalate also plays an important plasticizing role, making these products have good performance and durability.

The Advantages Of Diisooctyl Phthalate

From the perspective of materials science, the core advantage of Diisooctyl Phthalate is first reflected in its excellent processing performance. Its compatibility index with PVC is as high as 0.96, which is much higher than most alternative plasticizers, which ensures that the plasticization system will not phase separate or bleed during long-term use.

From the perspective of material performance balance, PVC products plasticized with Diisooctyl Phthalate can maintain stable mechanical properties in the range of -30℃ to 80℃, with a tensile strength retention rate of more than 85% and an elongation at break of more than 300%. This wide temperature range applicability enables it to meet the use requirements in extreme environments.

In terms of technical compatibility, Diisooctyl Phthalate can form a synergistic effect with auxiliary plasticizers such as epoxy soybean oil and trimellitic acid esters, and regulate the hardness, resilience and flame retardant properties of the material through the compounding system. This flexibility in formula design enables it to adapt to the differentiated requirements of different industries for material properties.

In terms of migration control, although there are controversies, modern processes can control its migration amount to less than 0.5mg/dm² through surface cross-linking treatment, nanofiller doping and other technologies, meeting the international standards for food contact materials. In terms of environmental adaptability, the biodegradation half-life of Diisooctyl Phthalate plasticized products in soil is about 100 years. This durability has become a competitive advantage in the field of engineering materials that require long-term service.

On the application side, the breakthrough of microencapsulation technology has achieved the controlled release of Diisooctyl Phthalate, which has significantly improved its application safety in sensitive fields such as medical catheters. These technological innovations not only continue the technical value of traditional plasticizers, but also open up new possibilities for its continued application under strict environmental standards.

Economic advantages are the key factor for Diisooctyl Phthalate to continue to dominate the market. Its raw material isooctyl alcohol can be mass-produced through the butene carbonylation process, and the unit cost is about 40% lower than that of bio-based plasticizers. Under the same plasticizing effect, its addition amount can be reduced by 15-20% compared with dibutyl phthalate. This cost-effectiveness advantage is particularly prominent in cost-sensitive fields such as thin-walled products and foaming materials.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Diisooctyl Phthalate

Diisooctyl Phthalate Manufacturer

Contact Us

As an experienced Diisooctyl Phthalate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diisooctyl Phthalate CAS 27554-26-3 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.