Triethyl Acetyl Citrate CAS 77-89-4

Factory wholesale Triethyl Acetyl Citrate CAS 77-89-4

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Triethyl Acetyl Citrate

CAS:77-89-4

MOQ: 1KG

Directory Guidance on Triethyl Acetyl Citrate

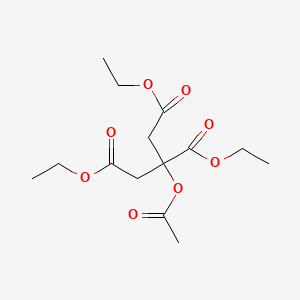

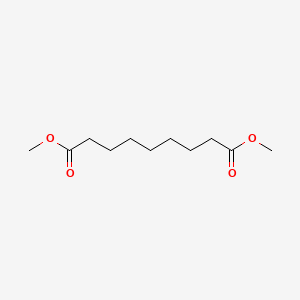

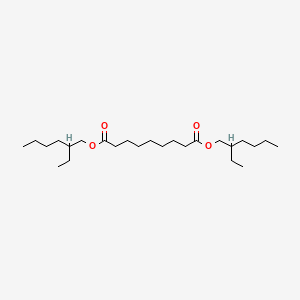

Chemical Structure

Basic Info:

| Melting Point | -42°C |

| Boiling Point | 228-229 °C/100 mmHg (lit.) |

| Density | 1.136 g/mL at 25 °C (lit.) |

| Pour Point | -42 |

Titanium Tetrachloride Introduction:

Triethyl Acetyl Citrate is a multifunctional plasticizer with excellent performance. It belongs to the citrate plasticizer, with a molecular formula of C18H30O8 and a molecular weight of 390.42. At room temperature and pressure, it usually appears as a colorless or light yellow transparent oily liquid with a slight ester odor. This odor is relatively mild and non-pungent, easy to be accepted by people, and has certain advantages in some odor-sensitive application scenarios.

From the perspective of chemical structure, Triethyl Acetyl Citrate is made by esterification of citric acid and ethanol and further acetylation. This unique chemical structure gives it many excellent performance characteristics. First of all, it has good compatibility and can be miscible with a variety of polymers, such as polyvinyl chloride (PVC), polyvinyl acetate (PVAc), cellulose acetate (CA), etc. This wide compatibility allows it to play a role in the production of different types of plastic products to meet diverse processing and application needs.

Triethyl Acetyl Citrate has good oil resistance, light resistance and mildew resistance. These properties enable it to maintain the quality of plastic products in a more complex use environment, extend its service life, and reduce the occurrence of product performance degradation or damage caused by environmental factors.

It also has low volatility and low migration, which means that during the long-term use of plastic products, Triethyl Acetyl Citrate is not easy to volatilize and lose from the material or migrate to other substances, thereby ensuring the lasting stability of the performance of plastic products.

In terms of production and preparation, the synthesis process of Triethyl Acetyl Citrate has been relatively mature after years of research and development. Generally, its synthesis process mainly includes two key steps: esterification reaction and acetylation reaction. The esterification reaction is to react citric acid with ethanol under the action of a catalyst to generate the corresponding ester intermediate. Then, the intermediate is further structurally modified by acetylation reaction to finally obtain the Triethyl Acetyl Citrate product.

In the production process, precise control of reaction conditions, such as temperature, pressure, catalyst dosage, reaction time, etc., has an important impact on product quality and yield. Different manufacturers may adopt different process routes and optimization plans based on their own technical strength and equipment conditions to improve production efficiency, reduce costs and ensure that product quality meets relevant standards.

Nature and Specifications:

| Item | Specification |

| Product Name | Triethyl Acetyl Citrate |

| CAS No. | 77-89-4 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Form | Liquid |

| Color | Colourless |

| Odor | odorless |

| BRN | 1804947 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Triethyl Acetyl Citrate

Triethyl Acetyl Citrate has an extremely wide range of applications, covering numerous fields of plastic product processing. It is one of the important plasticizers in polyvinyl chloride (PVC) products. It has good compatibility with PVC and can penetrate deeply into the interior of PVC resin particles, forming effective lubrication and dispersion between PVC molecular chains, thereby reducing the interaction force between PVC molecular chains, making PVC materials easier to plasticize and shape during processing, and endowing products with good flexibility, elasticity, and cold resistance.

For example, in the production of PVC hoses, soft PVC toys, PVC packaging films, and other products, using Triethyl Acetyl Citrate as a plasticizer can enable the product to maintain good mechanical properties while having flexibility and a certain degree of elasticity, meeting different usage needs.

Triethyl Acetyl Citrate also has important application value in the field of polyvinyl acetate (PVAc) lotion. PVAc lotion is a commonly used adhesive and coating binder, which has the advantages of high bonding strength and low cost, but its water resistance and cold resistance need to be improved. These properties of PVAc lotion can be effectively improved by adding an appropriate amount of Triethyl Acetyl Citrate.

Triethyl Acetyl Citrate can interact with PVAc molecules, regulate the crystallization behavior and intermolecular forces of PVAc molecular chains, so that after the PVAc emulsion is dried and formed into a film, the formed film has better flexibility, water resistance and cold resistance. This is of great significance for improving the bonding performance of PVAc adhesives in humid environments and the construction and use performance of coatings in low temperature environments, so that it can be better used in architectural decoration, wood processing and other fields.

Triethyl Acetyl Citrate has good compatibility with CA, can be uniformly dispersed in CA resin, effectively reduce the glass transition temperature of CA molecular chains, and improve the flexibility and processability of CA materials. This makes CA products easier to form during processing and have better impact resistance and cold resistance during use, which can meet the performance requirements of CA products in different application scenarios, such as in the fields of optical films and packaging materials.

In the production of products such as plastic films and plastic containers for food packaging, the use of Triethyl Acetyl Citrate as a plasticizer can ensure that the packaging materials do not release substances harmful to the human body during contact with food, while also meeting the requirements of packaging materials for properties such as flexibility, oil resistance, and cold resistance. Effectively protect the quality and safety of food and extend its shelf life.

The Advantages Of Triethyl Acetyl Citrate

From the perspective of product advantages, the core competitiveness of Triethyl Acetyl Citrate is first reflected in its excellent environmental performance. Compared with phthalate plasticizers, it does not contain any substances restricted by the EU REACH regulations, and has passed FDA 21 CFR 175.300 certification, and can be directly used in food packaging materials.

The advantage of chemical stability enables Triethyl Acetyl Citrate to maintain stable performance in harsh environments. Experimental data show that after PVC products containing this product are placed in an environment of 85°C and 90% relative humidity for 1000 hours, the tensile strength only decreases by 2.3%, which is much lower than the control group using traditional plasticizers.

In terms of processing performance, Triethyl Acetyl Citrate has a flat viscosity-temperature curve, and there will be no phase separation during the mixing process with the resin. The plasticization efficiency (measured in Shore hardness) is 15%-20% higher than DOP, which means that less addition is required to achieve the same flexibility, thereby reducing production costs. For products that require secondary processing (such as heat sealing or welding), its migration resistance can avoid bonding failure caused by surface precipitation.

From an economic perspective, the synthetic raw materials (citric acid, ethanol) of Triethyl Acetyl Citrate are bulk chemicals with stable supply and small price fluctuations. The esterification acetylation continuous flow technology used in the production process reduces energy consumption by about 30% and wastewater discharge by 40%, meeting the requirements of clean production. For downstream users.

The wide processing window of Triethyl Acetyl Citrate (applicable temperature range -30 ° C to 180 ° C) is compatible with various molding processes such as injection molding, extrusion, and rolling, without the need for additional adjustment of equipment parameters. The Life Cycle Assessment (LCA) indicates that the carbon footprint of plastic products using it is 18% lower than that of traditional solutions.

In terms of technological innovation, the molecular structure of Triethyl Acetyl Citrate has room for further functional modification. By adjusting the ratio of acetyl and ethoxy groups, customized products for specific materials (such as engineering plastics and elastomers) can be developed. At present, studies have combined it with nanofillers (such as montmorillonite and graphene) to successfully prepare smart materials with both high strength and self-healing functions. This scalability ensures its continued competitiveness in future materials science.

Contact Us

Product Package picture:

Related References:

chemicalbook-Triethyl Acetyl Citrate

Triethyl Acetyl Citrate Manufacturer

Contact Us

As an experienced Triethyl Acetyl Citrate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Triethyl Acetyl Citrate CAS 77-89-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.