Dibutyltin Dilaurate CAS 77-58-7

Factory wholesale Dibutyltin Dilaurate CAS 77-58-7

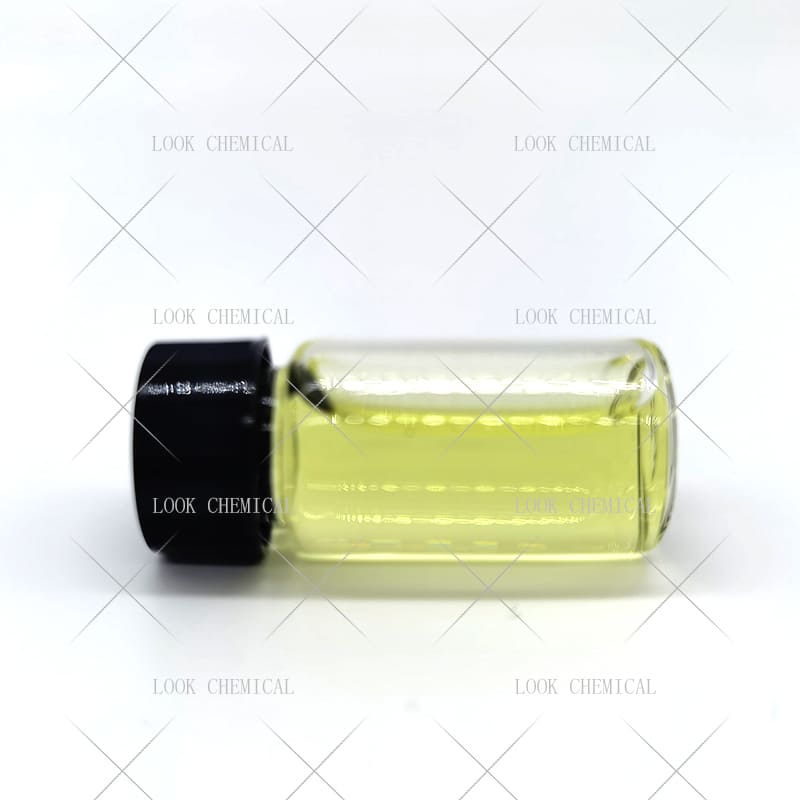

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dibutyltin Dilaurate

CAS: 77-58-7

MOQ: 1KG

Directory Guidance on Dibutyltin Dilaurate

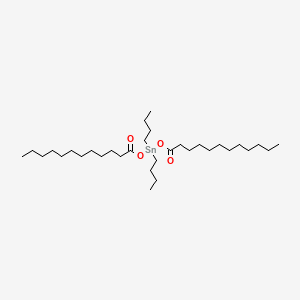

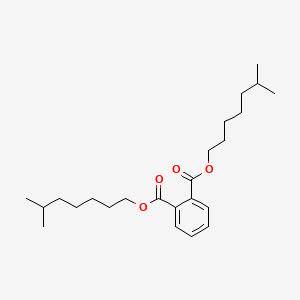

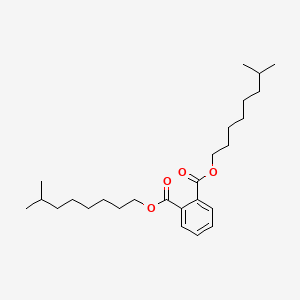

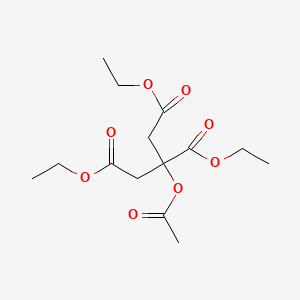

Chemical Structure

Basic Info:

| Melting point | 22-24°C |

| Boiling point | >204°C/12mm |

| density | 1.066 g/mL at 25 °C(lit.) |

| vapor pressure | 0.2 mm Hg ( 160 °C) |

| refractive index | n20/D 1.471(lit.) |

| Fp | >230 °F |

| storage temp. | Store below +30°C. |

Product Introduction:

Dibutyltin Dilaurate is an organotin compound with an intriguing chemical structure and wide range of industrial applications. This light yellow or colorless oily liquid, chemically formulating as C32H64O4Sn, and molecular weight estimated at 631.56g/mol can be found as light yellow liquid with excellent transparency, lubricity, weather resistance characteristics that make it especially suited to plastics, rubber and coating industries.

Dibutyltin Dilaurate finds primary application in both plastics and rubber industries, particularly heat stabilization for soft and semi-soft PVC products such as films, pipes and artificial leather. Furthermore, it can act as a catalyst to aid polyurethane foam’s foaming and curing processes; rubber industries often utilize it as a rubber curing agent that accelerates vulcanization processes; its excellent weather resistance makes it popular choice in coating and electronics applications as well.

Dibutyltin Dilaurate provides many benefits; however, its toxicity may cause adverse impacts to aquatic organisms and the environment. Therefore, safety regulations must be strictly observed during use and handling to minimize harm to both environmental protection efforts and human health. Furthermore, with increased environmental protection standards coming into effect soon, its production process could become more environmentally-friendly – using microwave heating technology and ultrasonic cavitation effects for increased reaction efficiency for example.

Dibutyltin Dilaurate is an organotin compound with multiple uses in several industries such as plastics, rubber and coatings thanks to its diverse physical, chemical and catalytic properties. However, due to its toxic nature it must be handled carefully in order to ensure safety and sustainable development.

Nature and Specifications:

| Item | Specification |

| Product Name | Dibutyltin Dilaurate |

| CAS No. | 77-58-7 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| solubility | <1.43mg/l |

| form | Oily Liquid |

| Specific Gravity | 1.066 |

| color | Clear pale yellow |

| Water Solubility | <0.1 g/100 mL at 20 ºC |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Dibutyltin Dilaurate is an organotin compound widely utilized across industrial fields due to its superior catalytic performance and thermal stability. Dibutyltin Dilaurate’s use in plastics production, specifically as a heat stabilizer/catalyst for polyvinyl chloride (PVC) processing has proven invaluable, preventing discoloration or degradation due to thermal decomposition during processing while improving processing stability as well as performance of final products.

Dibutyltin Dilaurate can help soft PVC products (plastic film, artificial leather, hose etc) achieve increased thermal stability and transparency; for harder PVC products (pipes/profiles etc), Dibutyltin Dilaurate enhances mechanical properties as well as weather resistance of materials; while for polyurethane foam production it acts as an auxiliary catalyst between isocyanates/polols reaction as well as curing process speed up.

Under heating conditions, the material decomposes to form active tin ions that enhance cross-linking reactions between sulfur and rubber chains and form an effective three-dimensional network structure. Dibutyltin Dilaurate is widely utilized in the production of rubber products like tires, hoses and shoes; its use reduces production times significantly while increasing efficiency. Due to its toxicity however, its application in this industry must abide by stringent environmental protection and safety regulations.

Dibutyltin Dilaurate plays an essential role in the coating industry as both a drier and catalyst, speeding up drying times while improving adhesion, weather resistance and adhesion properties of coatings. When used as part of two-component waterborne polyurethane coating systems, Dibutyltin Dilaurate promotes cross-linking reactions between isocyanate and polyol to quickly form tough protective films; additionally it can speed up curing times for two component waterborne coating systems as two component waterborne systems can quickly cure quickly while simultaneously curing and creating tough protective films; finally it can also help enhance chemical resistance as well as weather resistance of coatings significantly.

Dibutyltin Dilaurate is widely utilized in the electronics industry to produce packaging materials and adhesives, such as electronic packaging materials and conductive adhesives. As a catalyst, it promotes curing of silicone rubber while increasing mechanical properties and electrical insulation of packaging materials. When applied directly to electronic component packaging, Dibutyltin Dilaurate can accelerate curing process so as to form good seal effect with electronic components from environmental influence; similarly it helps solidification colloids while improving electrical conductivity and bond strength of adhesive production processes.

1. Highly catalytic activity

Dibutyltin Dilaurate has extremely high catalytic activity and can easily facilitate many chemical reactions at low temperatures. For example, in the synthesis of polyurethanes, it can very significantly increase the reaction rate between isocyanates (-NCO) and polyols (-OH), shorten the reaction time, and thus improve production efficiency. In addition, Dibutyltin Dilaurate also showed good catalytic properties in esterification and condensation reactions, helping to reduce the formation of by-products and improve the purity and quality of the product.

2. Good stability and selectivity

Dibutyltin Dilaurate has the advantages of high selectivity for specific reactions, controllable reaction path and low incidence of side reactions. For example, during polyurethane synthesis, Dibutyltin Dilaurate prevents isocyanates from reacting with water, thereby minimizing carbon dioxide production and increasing product purity. In addition, Dibutyltin Dilaurate has excellent thermal and hydrolytic stability and remains active over a wide pH range. It is suitable for complex reaction systems.

3. Environmental protection, low toxicity

Dibutyltin Dilaurate In the case of toxic heavy metal catalysts, toxicity and effects on the environment and human health are much less. Its low toxicity makes it a good alternative to traditional, highly toxic old catalysts under increasingly stringent environmental regulations. In addition, Dibutyltin Dilaurate can also be recycled by chemical treatment or physical separation, further reducing resource waste and production costs.

4. Versatility and wide range of applications

Dibutyltin Dilaurate is a highly efficient catalyst with thermal stability and lubricity, so it has a variety of uses. Its application fields include polyurethane, polyvinyl chloride, PVC, silicone rubber, coatings, adhesives and so on. For example, in PVC processing, Dibutyltin Dilaurate can be used as a heat stabilizer to effectively prevent high temperature degradation, thereby extending the service life of the material. In flexible electronics applications, Dibutyltin Dilaurate can enhance the flexibility and conductivity of substances, thereby advancing the development of related technologies.

5. Cost-effectiveness and sustainability

The high catalytic activity of Dibutyltin Dilaurate can greatly reduce the reaction time and production costs. Like other compounds, with the development of green chemistry technology, its synthetic route is constantly upgraded, such as microwave heating technology, ultrasonic cavitation effect, etc., can further improve the reaction rate and yield, these improvements can not only be regarded as improving production efficiency, but also meet the requirements of sustainable development, and be more competitive in future industrial applications.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dibutyltin Dilaurate

Dibutyltin Dilaurate Manufacturer

Contact Us

As an experienced Dibutyltin Dilaurate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dibutyltin Dilaurate CAS 77-58-7 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.