Dioctyl Phthalate CAS 117-84-0

Dioctyl Phthalate CAS 117-84-0 With Quality Wholesale

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dioctyl Phthalate

CAS: 117-84-0

MOQ: 1KG

Directory Guidance on Dioctyl Phthalate

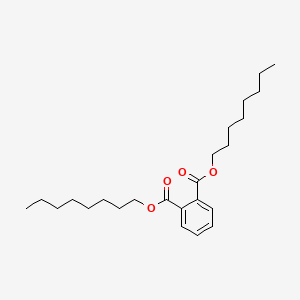

Chemical Structure

Basic Info:

| Melting point | -25℃ |

| Boiling point | 380 °C |

| density | 0.980 g/mL at 20 °C(lit.) |

| vapor pressure | 5(x 10-8 mmHg) at 82 °C, 500 at 132 °C (Gross and Colony, 1973) |

| refractive index | n20/D 1.485 |

| Fp | 219 °C |

Product Introduction:

Dioctyl Phthalate (DOP), commonly referred to by its acronym, is an ester compound widely utilized as an additive plasticizer in plastic and rubber industries – especially polyvinyl chloride plastics. It possesses both two octyl (C8H17) substituents and thus belongs to its ester family of compounds.

Dioctyl Phthalate (DOP) is an insoluble, colorless or pale yellow oily liquid at room temperature with an aromatic scent, insoluble in water but soluble in many organic solvents such as alcohols, ethers and benzene.

Dioctyl Phthalate boasts excellent physical and chemical properties. With a boiling point of around 386degC and melting points as low as 50degC, as well as good heat resistance and cold resistance properties. As it remains liquid over an extensive temperature range it makes an ideal plasticizer material. Furthermore, its density of around 0.986g/cm3 paired with excellent electrical insulating properties means its use in products like cables or insulation materials has increased considerably in recent years.

Chemical stability-wise, Dioctyl Phthalate has proven itself remarkably stable to oxidation, acid and alkali attacks and high temperatures; it may however volatilize or degrade at higher temps but its volatility remains relatively low allowing its plasticizing effects in plastic products to continue for an extended period.

Dioctyl Phthalate can slowly migrate or volatilize over time, altering physical properties of materials. Due to poor light stability and UV radiation exposure, Dioctyl Phthalate’s plasticizing effect could become compromised over time and eventually lose all plasticizing effect altogether.

Dioctyl Phthalate’s stable properties and relatively reasonable cost make it widely applicable across a range of fields, not just PVC plastics plasticizing effects. As well as PVC plastic plasticization effects it also serves as an ingredient or solvent in cosmetics, paints, coatings textiles and agricultural products – as well as providing plasticizing properties in PVC plastics themselves.

Nature and Specifications:

| Item | Specification |

| Product Name | Dioctyl Phthalate |

| CAS No. | 117-84-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 219 °C |

| storage temp. | 2-8°C |

| solubility | Chloroform (Slightly), Methanol (Slightly) |

| form | Oily Liquid |

| color | Colourless |

| Specific Gravity | 0.98 |

| Water Solubility | Insoluble in water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As the most widely used plasticizer variety in the plastic industry field, Dioctyl Phthalate has a market share of more than 30% in the global plasticizer market. Its core value lies in its outstanding plasticizing effect on polyvinyl chloride (PVC) materials: when the addition amount reaches 30-50% of the resin mass, it can reduce the glass transition temperature of PVC products from 80℃ to below -30℃, while maintaining the tensile strength within the range of 10-15 MPa. This unique performance balance makes it the preferred plasticizer for soft PVC products and is widely used in the manufacturing of flexible materials such as artificial leather, cable sheaths, and hoses. During the processing, Dioctyl Phthalate exhibits excellent thermal stability and low volatility, and can effectively adapt to the temperature conditions of different molding processes such as extrusion, calendering, and injection molding.

In the field of rubber products, Dioctyl Phthalate is mainly used as an auxiliary plasticizer to improve the processing performance of rubber compounds. The long-chain alkyl structure in its molecules can penetrate between the rubber molecular chains, reduce the Mooney viscosity of the rubber compound, and improve the mixing efficiency. Especially in polar rubber systems such as nitrile rubber and chloroprene rubber, the plasticizing efficiency of Dioctyl Phthalate is approximately 20% higher than that of traditional petroleum-based plasticizers, while it does not significantly affect the mechanical properties of the vulcanized rubber. In a dynamic usage environment, rubber products with this product added exhibit better resistance to flex fatigue, which is particularly important for components such as seals and shock-absorbing elements that are subject to periodic stress for a long time.

In the coating industry, Dioctyl Phthalate is mainly used as a film-forming aid and leveling agent. In solvent-based coating systems, it can effectively reduce the surface tension of the resin solution and promote the spreading and leveling of the coating on the substrate. For systems such as acrylic resin and alkyd resin, adding 2-5% of this product can increase the gloss of the coating film by 15-20%, while reducing the occurrence of orange peel phenomenon. In the field of powder coatings, the plasticizing effect of Dioctyl Phthalate helps to reduce the melt viscosity of the resin and improve the leveling property and edge coverage of the coating. It is worth noting that in some special coating formulations, it also functions as a flame retardant synergist, and its decomposition temperature has a good match with the activation temperature of common flame retardants.

The application of Dioctyl Phthalate in the field of medical devices is mainly concentrated in products with high requirements for material flexibility, such as infusion bags, catheters, etc. Under strict quality control, the impurity content of medical-grade Dioctyl Phthalate is controlled at the ppb level, especially the limit standards for harmful substances such as heavy metals and peroxides are much higher than those of industrial-grade products. When in contact with human tissue, it shows good biological inertness, and its migration amount is still less than 50 μg/cm² after 30 days of immersion in 37℃ saline, which fully meets the biocompatibility requirements of medical devices. In the pharmaceutical industry, Dioctyl Phthalate is also used as a carrier material for sustained-release preparations, and the release rate of active ingredients is controlled by adjusting its compatibility with drugs.

In the automotive industry, the application of Dioctyl Phthalate runs through multiple links such as interior and exterior trims, sealing systems, and wiring harness protection. Among the dashboard surface materials, Dioctyl Phthalate-modified PVC materials can not only meet the aesthetic requirements of texture clarity, but also have practical properties of aging resistance and scratch resistance.In recent years, with the development of the lightweight trend of automobiles, the application proportion of Dioctyl Phthalate in microporous foaming materials has continued to rise, and its plasticizing efficiency can help reduce the foaming temperature by about 15-20℃.

The demand for Dioctyl Phthalate in the field of environmentally friendly materials shows a structural growth trend. In the biodegradable plastic system, its use as a compatibilizer can effectively improve the interfacial bonding strength between polylactic acid (PLA) and natural materials such as starch, and increase the elongation at break of the composite material from 5% to more than 80%. In the processing of recycled plastics, its addition can compensate for the molecular chain breakage caused by multiple processing and restore the impact strength of the recycled material to 85% of the original material. It is worth noting that the application of Dioctyl Phthalate in new electronic packaging materials is expanding. Its low dielectric loss characteristics are highly consistent with the needs of 5G communication materials, and it shows unique advantages in dielectric substrates, antenna covers and other components.

The advantage of Dioctyl Phthalate lies in its excellent balance. Compared with other types of plasticizers, it achieves the best balance in multiple key indicators such as plasticizing efficiency, durability, and processing adaptability. Compared with diisononyl Phthalate (DINP), the plasticizing efficiency of Dioctyl Phthalate for PVC is approximately 12% higher, and compared with the environmentally friendly plasticizer tributyl acetyl citrate (ATBC), its migration resistance is increased by more than three times. This comprehensive performance advantage enables it to always maintain an irreplaceable position in demanding application scenarios. Especially in a dynamic usage environment, the material modified by Dioctyl Phthalate can withstand more than 10^6 bending cycles without embrittlement and cracking, which is difficult for most alternative products to achieve.

In terms of safety and environmental protection, Dioctyl Phthalate has fully complied with modern industrial standards through continuous technological improvements. In response to the early controversy over the environmental impact of phthalates, the industry has reduced the volatile organic compound (VOC) emissions of Dictyl Phthalate by over 70% through process optimization. At present, the acute oral toxicity (LD50) of the mainstream products is greater than 20 g/kg, and the ecotoxicity test shows that the 96h-LC50 against aquatic organisms exceeds 100 mg/ L. These data all meet the international chemical safety standards. Under the framework of the REACH regulation, Dioctyl Phthalate has completed full registration and meets the compliance requirements of the SVHC candidate substance list. By-products in the production process, such as monoesters of phthalates, can have their content controlled below 0.01% through advanced distillation technology.

Economic advantage is the key element for Dioctyl Phthalate to maintain market competitiveness. From the perspective of raw material cost analysis, its basic raw materials, phthalic anhydride and 2-ethylhexanol, are both bulk chemicals. The global annual production capacity exceeds 5 million tons, and the stable supply chain ensures that the price fluctuation range is controlled within 5%. Compared with new bio-based plasticizers, the unit cost of Dioctyl Phthalate is only 40-60% of it, which is decisive for the plastic processing industry with huge usage. From the perspective of the full life cycle cost, the materials modified by Dioctyl Phthalate can maintain stable performance for more than 10 years under normal usage conditions, and the maintenance and replacement frequency is reduced by more than 30% compared with the alternative products. This economic advantage is particularly evident in long-cycle application scenarios such as infrastructure projects and automotive manufacturing.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dioctyl Phthalate

Dioctyl Phthalate Manufacturer

Contact Us

As an experienced Dioctyl Phthalate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dioctyl Phthalate CAS 117-84-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.